ProductPRODUCT

Featured products

Contact Us

- GE

- IS220PRTDH1B

- Resistance Temperature Device (RTD) Input Module

- USA

- 8.26 cm (H) × 4.19 cm (W) × 12.1 cm (D)

- 0.91kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 161

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Product Introduction

-

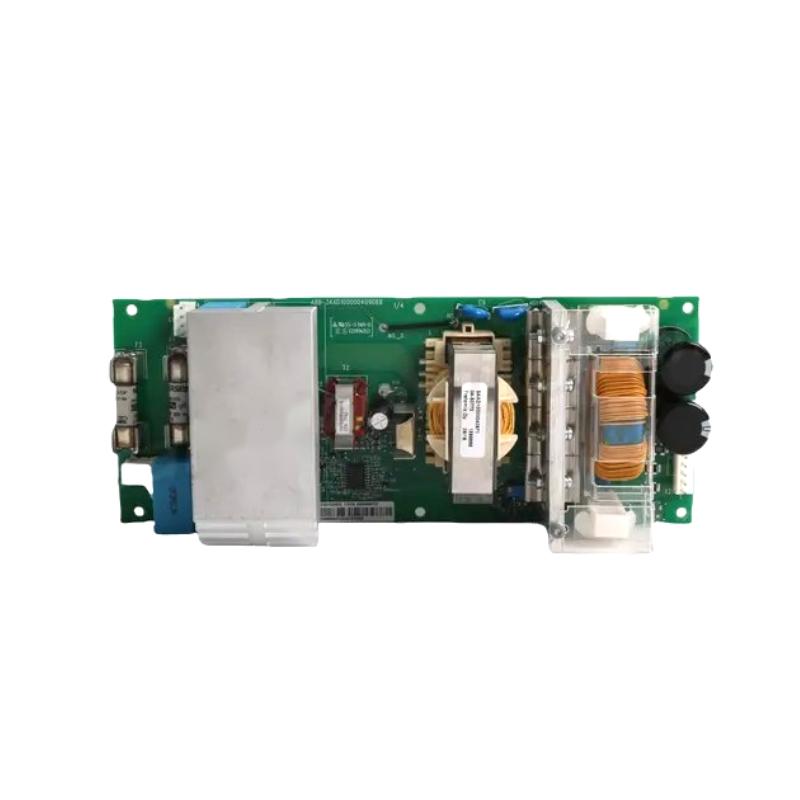

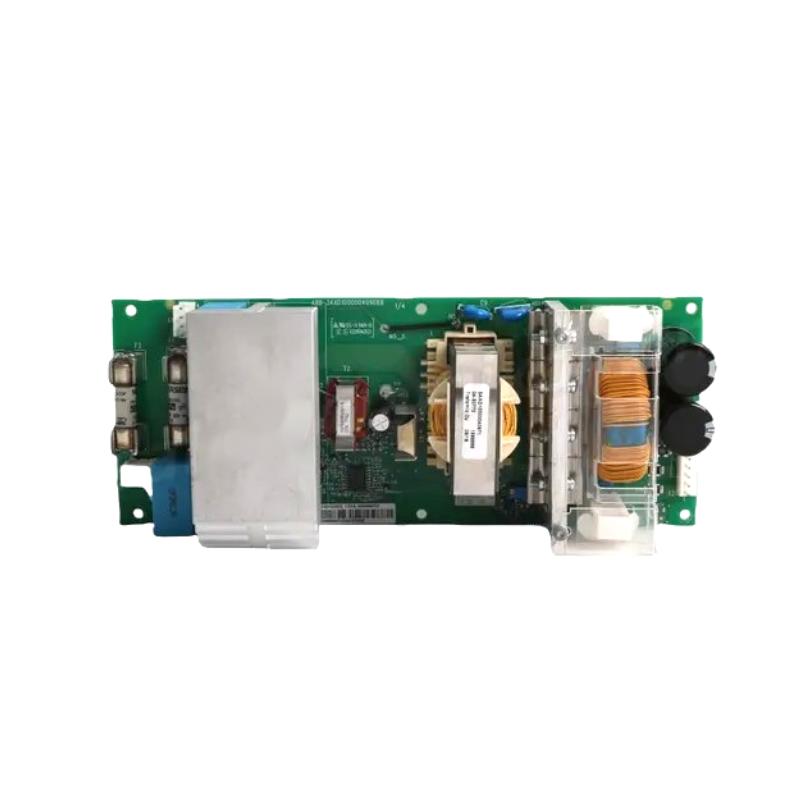

Brand: GE

-

Series: Mark VIe I/O Modules

-

Model: IS220PRTDH1B

-

Product Type: RTD (Resistance Temperature Detector) Input Module

-

Description:

The IS220PRTDH1B is a precision RTD input I/O pack designed for industrial control systems within the Mark VIe architecture. It accepts RTD (platinum resistance) sensor inputs—such as Pt100 or Pt1000 types—and converts the resistance signal into digital data for the control system. This module is engineered for high‑reliability measurement in applications like turbine control, power generation, petrochemical plants, and other heavy‑industrial environments where accurate temperature monitoring is essential. The module supports multiple input channels, high resolution measurement, rugged environmental tolerance, and integration with the Mark VIe backplane and network infrastructure.

Specifications

Here are the reference specifications for IS220PRTDH1B:

| Parameter | Specification |

|---|---|

| Number of channels | 8 RTD input channels (typical) |

| Supported RTD sensor types | Pt100, Pt1000 (and other standard platinum RTDs) |

| Input measurement range | e.g. ‑200 °C to +850 °C (sensor‑dependent) |

| Resolution / A/D converter | Typically 14‑bit (or higher resolution indicated) |

| Power supply voltage | 24 V DC nominal (or 28 V DC typical for I/O pack) |

| Current draw | ~0.24 A at 28 VDC (example) |

| Operating temperature | ‑30 °C to +65 °C (industrial environment) |

| Storage temperature | ‑40 °C to +85 °C (storage) |

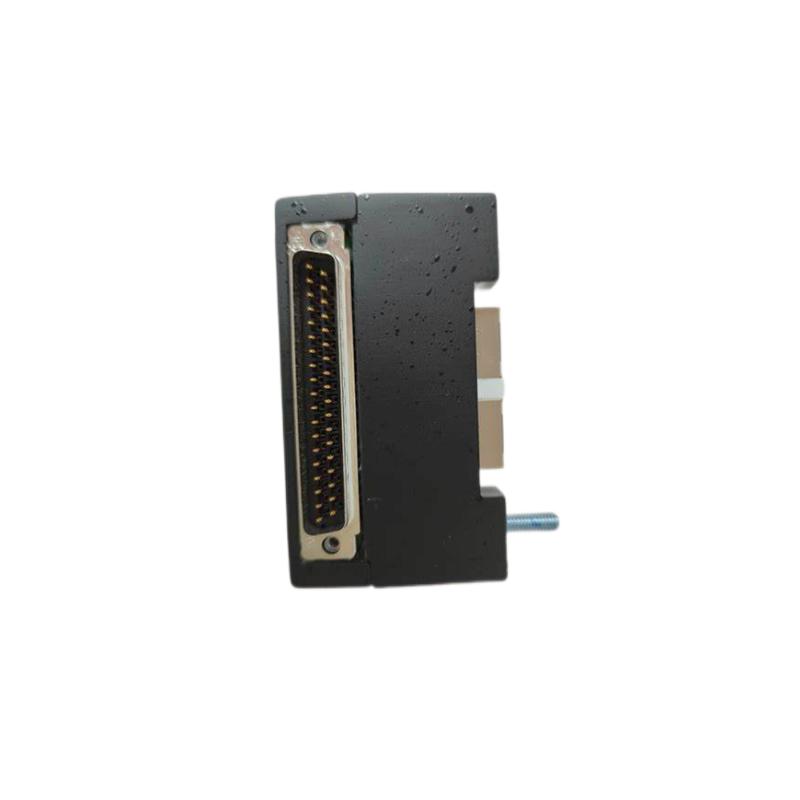

| Dimensions | ~8.26 cm (H) × 4.19 cm (W) × 12.1 cm (D) (example) |

| Weight | < 0.91 kg (2 lbs) (≈0.9 kg) (example) |

| Communication interface | Backplane / rack compatible with Mark VIe I/O architecture |

| Wiring/support | Supports 2‑wire, 3‑wire, 4‑wire RTD connections; maximum lead resistance ~15 Ω |

| Certifications | UL listing, ATEX/Zone/Division 2 hazardous‑area support (depending version) |

Applications

Typical application fields for the IS220PRTDH1B module include:

-

Power generation plants: Monitoring critical temperature points such as turbine casings, bearing temperatures, exhaust gas paths, feedwater heaters.

-

Oil & gas / petrochemical industries: Using RTD sensors for temperature measurement on pipelines, heat exchangers, reactor vessels, process pipes—especially in hazardous/explosive zones.

-

Heavy industrial automation: In plants with harsh environmental conditions (vibration, temperature extremes, dust), the RTD module provides reliable temperature input data for control systems.

-

DCS / PLC / turbine control systems: As part of the Mark VIe I/O rack architecture, the module feeds temperature data into the control logic, allowing precise monitoring, alarm/trip logic, optimization of thermal processes.

Advantages

The IS220PRTDH1B module offers several distinct advantages:

-

High‑precision measurement – Supports accurate RTD input with low drift and high resolution, enabling reliable temperature control.

-

Multi‑channel input – Up to 8 channels in one module reduce rack space and wiring complexity compared to single‑channel solutions.

-

Rugged industrial design – Capable of withstanding harsh conditions (temperature range, vibration, electrical noise) common in power plants and heavy industry.

-

Seamless integration – Fully compatible with Mark VIe rack/backplane systems, sharing diagnostics, communications and maintenance infrastructure.

-

Flexible wiring support – Works with 2/3/4‑wire RTD sensors and compensates for lead resistance, improving installation flexibility.

-

Hazardous‑area capable – Versions include certifications for ATEX/UL/Zone/Division 2, enabling use in explosive gas environments.

-

Efficient maintenance – Front‑panel diagnostics and integration with system tools allow quicker fault identification and replacement, reducing downtime.

-

Cost‑effective footprint – Multiple measurement channels in a compact module help reduce overall cabinet size and wiring cost.

Recommended Models

Same Series / Related Models (Mark VIe I/O)

Here are five other models from the same series or closely related I/O modules:

| Model | Series | Key Specifications |

|---|---|---|

| IS220PDIIH1B | Mark VIe Discrete Input | 16 isolated discrete input channels; ~1 kg |

| IS220PDIAH1B | Mark VIe Discrete Input | 24 input channels; 24 V DC; broader temperature rating |

| IS220PDOAH1B | Mark VIe Discrete Output | 16 isolated output channels; 24‑28 V DC; ~1.42 kg |

| IS220PAICH1B | Mark VIe Analog I/O | 8 analog input + 2 output channels; supports ±5 V/±10 V |

| IS220PCLAH1B | Mark VIe Analog I/O | High‑load analog I/O; designed for turbine applications |

Popular Models from the Same Brand (GE)

Here are five other highly used models from the same brand (GE) but different functional classes:

| Model | Application | Key Specifications |

|---|---|---|

| IS220UCSAH1A | Mark VIe Controller Module | CPU module; 18‑36 V DC; compact size |

| IS220PAOCH1B | Mark VIe Analog Output Module | 8 analog outputs; 4‑20 mA; high precision |

| IS220PTCCH1B | Mark VIe Thermocouple Input Module | 12 thermocouple input channels + 1 cold junction |

| IS220PPRFH1B | Mark VIe PROFIBUS Communications | PROFIBUS DP interface; 28 V DC nominal |

| IS220PHRAH1B | Mark VIe HART I/O Module | 10 analog input + 2 analog output; HART protocol support |

FAQ (Frequently Asked Questions)

Q1: What sensor types does the IS220PRTDH1B support?

A1: It supports platinum resistance temperature detectors (RTDs) such as Pt100 and Pt1000, allowing 2‑wire, 3‑wire or 4‑wire sensor connections.

Q2: How many channels are on this module?

A2: The module typically has 8 RTD input channels in one pack module.

Q3: What is the allowed input temperature range for sensors?

A3: It can accommodate RTD sensor measurement ranges such as roughly –200 °C to +850 °C depending on sensor type, wiring and configuration.

Q4: What is the operating ambient temperature for the module?

A4: The module is rated for an ambient operating temperature of approximately –30 °C to +65 °C (industrial grade).

Q5: What power supply is required for this module?

A5: The module requires a 24 V DC nominal supply (or 28 V DC typical in I/O rack) and draws around 0.24 A or similar under full load.

Q6: Is the module suitable for hazardous area installation?

A6: Yes. There are versions of the module that are certified for hazardous locations (e.g., ATEX Zone or Class I Division 2) when installed according to approved wiring practices.

Q7: How is the module installed in the control system rack?

A7: It is installed in the Mark VIe I/O rack/backplane. Wiring from the terminal board to the RTD sensors must be correct (2‑wire/3‑wire/4‑wire), and the module must be connected to the communication network.

Q8: What diagnostics or status indicators are available?

A8: Front‑panel LEDs indicate power, communication status, channel fault or attention. The control system can use diagnostics to log sensor open/short conditions, channel failure, or communication loss.

Q9: How does the module handle lead resistance in RTD wiring?

A9: The module supports 2/3/4‑wire RTD connections and can compensate for lead resistance (up to ~15 Ω) to maintain measurement accuracy.

Q10: What is the expected service life or reliability of the module?

A10: The module is built for long‑term industrial operation; its actual service life depends on installation environment (temperature, vibration, humidity) and maintenance practices. With regular inspection, it can reliably serve many years.