ProductPRODUCT

Featured products

Contact Us

- GE

- IS220PVIBH1A

- Mark VIe Vibration Monitor I/O Pack

- USA

- 8.26 cm (H) × 4.19 cm (W) × 12.1 cm (D)

- 0.38kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 157

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Product Introduction

-

Brand: GE

-

Series: Mark VIe I/O Modules (specifically the “PVIB” Vibration Monitoring Pack)

-

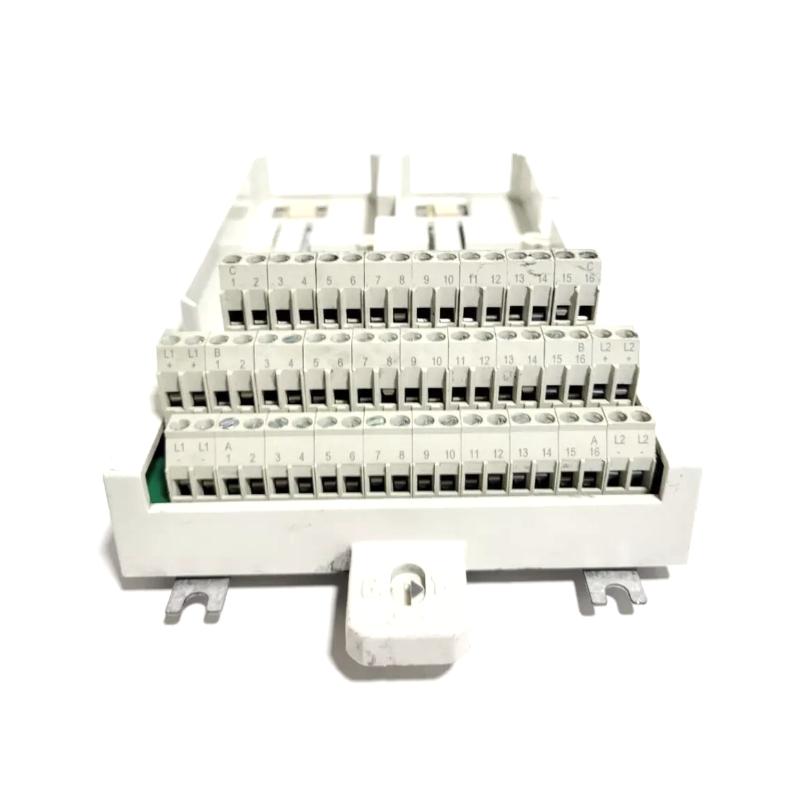

Model: IS220PVIBH1A

-

Product Type: Vibration‑monitoring I/O module / pack

-

Description:

The IS220PVIBH1A is designed as a high‑performance vibration monitoring I/O pack within the Mark VIe control system environment. It accepts input from proximity probes, accelerometers, velomitors or other vibration sensors and processes the signals for the control system. With multiple channels for both vibration and proximity signals, dual‑Ethernet ports for redundancy, and rugged industrial design, the module is intended for critical rotating‑machinery monitoring (such as turbines, compressors, pumps) in power plants and heavy‑industry applications where machinery health, reliability and early fault detection are vital.

Specifications

Below are key reference specifications for IS220PVIBH1A:

| Parameter | Specification |

|---|---|

| Number of channels | 13 channels for proximity and vibration sensors |

| Sensor types supported | Proximity probes, accelerometers, velomitors |

| Frame rates supported | 3.125 Hz, 6.25 Hz, 12.5 Hz, 25 Hz, 50 Hz, 100 Hz |

| Common‑mode voltage | Minimum ~5 V DC for sensor side |

| Probe power supply | ‑24 V DC, 12 mA load per transducer |

| Operating ambient temperature | ‑30 °C to +65 °C |

| Dimensions | Approximately 8.26 cm (H) × 4.19 cm (W) × 12.1 cm (D) |

| Weight | Approx. 0.38 kg |

| Communication interface | Dual Ethernet ports (redundant network paths) |

| Isolation / rugged design | Designed for heavy‑duty environments; supports high‑vibration, humidity etc. |

| Compatible terminal board | Vibration terminal board (TVBA) accessory for sensor connection |

Applications

Typical application scenarios for the IS220PVIBH1A module include:

-

Power generation plants: Monitoring vibration of turbines (gas or steam) – bearings, shafts, couplings – to detect early signs of misalignment, rotor imbalance or wear.

-

Oil & gas / petrochemical: On compressors, pumps, rotating equipment in refineries or offshore platforms where vibration monitoring is essential for reliability and safety.

-

Heavy industrial manufacturing: On large motors, gearboxes or rotating assemblies (e.g., conveyors, compressors) where continuous vibration data supports predictive maintenance and avoiding unplanned downtime.

-

Control system integration: Within distributed I/O racks of the Mark VIe system – the module brings vibration/proximity data into the automation/control logic, enabling alarm/trip logic, trending, diagnostics, and condition‑based maintenance.

Advantages

The IS220PVIBH1A offers several key advantages:

-

Multi‑channel vibration & proximity support – 13 channels reduce the number of separate modules needed and simplify configuration of multiple monitoring points.

-

High measurement fidelity – Supports both vibration (accelerometer) and proximity (shaft displacement) sensors, enabling comprehensive machine health insight.

-

Dual‑Ethernet redundancy – Network ports allow failover capability, improving system reliability in mission‑critical installations.

-

Robust industrial design – Operates over wide temperature range (‑30 °C to +65 °C), built for vibration/humidity/stress environments typical of power/industrial plants.

-

Compact and lightweight – With less than ~0.4 kg weight and small footprint, it is easier to mount in I/O racks and takes less space.

-

Seamless integration into Mark VIe architecture – Compatible with relevant terminal boards and system infrastructure, reducing engineering and installation complexity.

-

Pre‑emptive maintenance enablement – Real‐time vibration monitoring helps detect wear or failure modes early, reducing downtime and maintenance costs.

-

Reduced wiring and module count – Because of multiple channels in one pack, wiring and cabinet footprint can be optimized.

Recommended Models

Same Series / Related Models (Mark VIe I/O)

Here are five other models from the same series or closely related within the Mark VIe I/O family:

| Model | Series | Key Specifications |

|---|---|---|

| IS220PRTDH1B | Mark VIe RTD Input Module | 8 RTD input channels; temperature measurement support |

| IS220PDIOH1B | Mark VIe Discrete I/O Module | Combined discrete input & output; space‑saving design |

| IS220PDOAH1B | Mark VIe Discrete Output Module | 16 isolated outputs; for driving actuators/relays |

| IS220PAICH1B | Mark VIe Analog I/O Module | 8 analog inputs + 2 outputs; supports ±5 V/±10 V/0‑20 mA |

| IS220YDIAS1A | Mark VIe Discrete I/O Module | 16 channels (8 input + 8 output); 28 V DC nominal |

Popular Models from the Same Brand (GE)

Here are five other highly used models by the same brand (GE) though in different functional classes:

| Model | Application | Key Specifications |

|---|---|---|

| IS220UCSAH1A | Mark VIe Controller Module | Core CPU module; real‑time control; high reliability |

| IS220PAOCH1B | Analog Output Module | 8 analog outputs; high precision 4‑20 mA output range |

| IS220PTCCH1B | Thermocouple Input Module | 12 thermocouple channels + cold‐junction compensation |

| IS220PPRFH1B | PROFIBUS Communication Module | Supports PROFIBUS DP network for I/O communications |

| IS220PHRAH1B | HART I/O Module | 10 analog inputs + 2 outputs; supports HART protocol |

FAQ (Frequently Asked Questions)

Q1: What exactly does the IS220PVIBH1A monitor?

A1: It monitors vibration data (from accelerometers or velomitors) and proximity/shaft‑displacement signals (from proximity probes) on rotating machinery, converting those sensor signals into data for the control system.

Q2: How many sensor channels are supported?

A2: This module supports 13 independent channels for vibration and proximity monitoring.

Q3: What temperature range can it operate in?

A3: It is rated for ambient operation from approximately –30 °C up to +65 °C, suitable for industrial conditions.

Q4: What are the physical size and weight of the module?

A4: The dimensions are roughly 8.26 cm (height) × 4.19 cm (width) × 12.1 cm (depth) and the weight is about 0.38 kg.

Q5: What kind of network connectivity does it have?

A5: It uses dual Ethernet ports in a redundant configuration, allowing data to flow reliably into the control system even if one network path fails.

Q6: What sensor types can be used with it?

A6: The module supports accelerometers, velomitors, proximity probes and other vibration/displacement sensors appropriate for rotating machinery health monitoring.

Q7: Is the module suitable for hazardous or explosive areas?

A7: Yes, when installed with the correct accessory terminal board (e.g., vibration terminal board) and according to the approved configuration, the module is suitable for such environments.

Q8: How does it help reduce maintenance and downtime?

A8: By providing real‑time vibration and displacement data, the module enables early fault detection (bearing wear, imbalance, misalignment), allowing preventive maintenance rather than reactive repairs, thus reducing unplanned downtime.

Q9: Can this module be replaced easily if it fails?

A9: Yes, the pack‑module design allows replacement in the I/O rack; front‑panel status LEDs help identify fault conditions quickly, aiding maintenance response.

Q10: Why choose this module over simpler monitoring devices?

A10: Because it integrates into the Mark VIe control system architecture, supports many channels, offers redundancy, industrial durability and advanced processing – it is designed for mission‑critical rotating equipment monitoring, not just basic vibration sensing.