ProductPRODUCT

Featured products

Contact Us

- ABB

- BCU-02

- Control Units Hardware Manual

- Sweden

- 120 mm × 160 mm × 60 mm

- 1.4kg

- Control Units Hardware Manual

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 7

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

ABB BCU‑02 (3AUA0000110429) — Detailed Product Specification, Introduction, and Application Guide

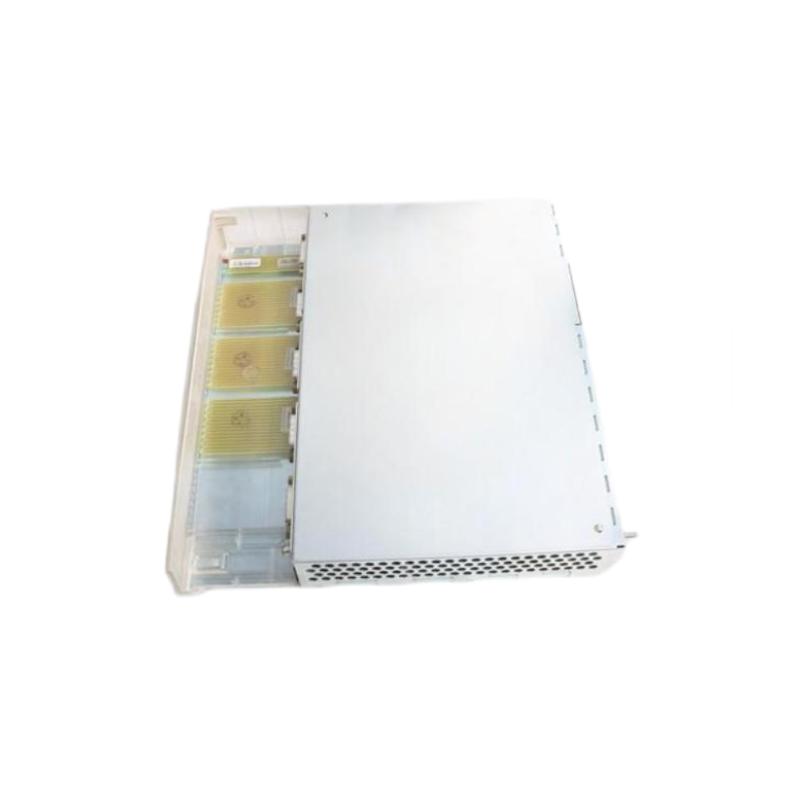

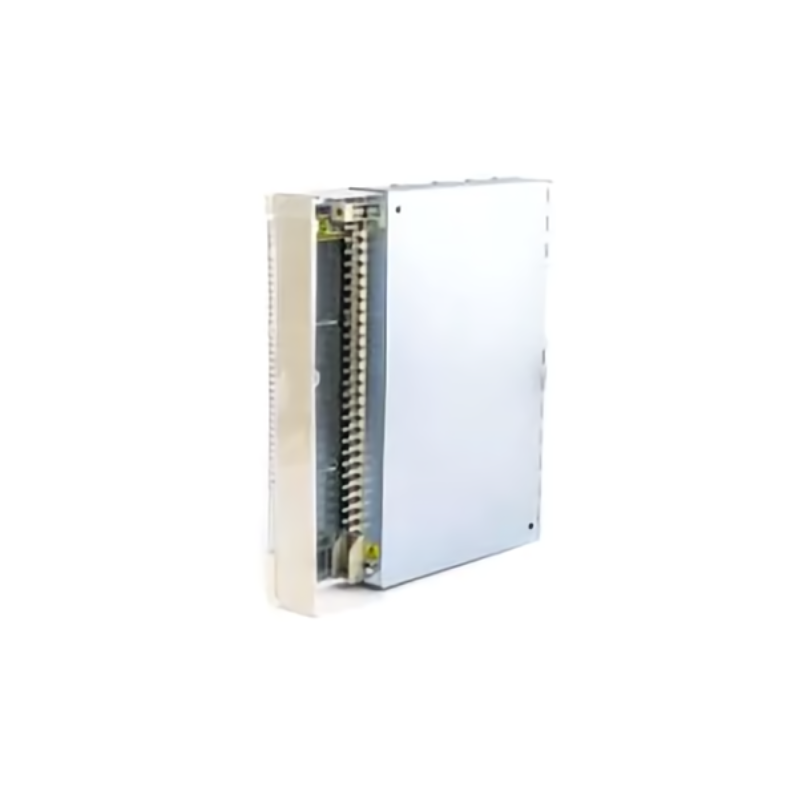

Product Overview

The ABB BCU‑02 (3AUA0000110429) is an industrial control and protection interface unit designed to manage, control, and monitor industrial processes and protective systems. The BCU‑02 serves as a bridge between field sensors, actuators, protective relays, and higher‑level automation controllers, providing reliable signal conditioning, logic processing, and secure communication paths.

Engineered for robustness and accuracy, the BCU‑02 supports continuous operation in demanding industrial environments, including manufacturing plants, power distribution systems, and process automation facilities. Its design focuses on modular expandability, multi‑signal support, diagnostics, and ease of maintenance. The BCU‑02 belongs to a family of control units used for mid‑range control and monitoring tasks where flexible I/O configurations and reliable performance are required.

Brand and Product Series

-

Brand: ABB

-

Product Series: BCU Control Units (Industrial Control & Protection Interface Series)

The BCU series comprises a range of intelligent interface and control modules designed to interface with sensors, PLCs, protection relays, and actuators. These units provide configurable I/O, communication pathways, logic functions, and diagnostics for advanced automation and protection applications in industrial and utility systems.

Product Introduction

The BCU‑02 is built to handle a broad range of analog and digital signals, perform preliminary logic processing, and transmit conditioned data to supervisory controllers or protective relays. It supports multiple signal formats, ensuring compatibility with diverse field devices such as transducers, switches, meters, and actuators.

Constructed with industrial‑grade components, the BCU‑02 incorporates signal isolation, noise suppression, and fault detection features, making it suitable for environments with electrical noise, temperature fluctuations, or mechanical vibration. Visual indicators and diagnostics facilitate rapid troubleshooting and maintenance.

The unit supports flexible configurations, allowing engineers to adapt the module to specific application requirements. Its modular architecture ensures that the BCU‑02 can be integrated into larger automation and control systems with minimal design effort.

Product Applications

Power Distribution Protection and Control

BCU‑02 is used in substations and power distribution networks to monitor electrical parameters, interface with protection relays, and perform logic functions related to fault detection and breaker control.

Process Automation

In manufacturing and process industries, the module acquires signals from temperature, pressure, flow, and level sensors, and transmits them to PLC/DCS for control actions.

Machine Automation and Safety Systems

BCU‑02 interfaces with emergency stop devices, safety interlocks, limit switches, and other safety components to implement machine safety logic and condition monitoring.

Energy Monitoring and Management

Used for energy parameter acquisition, load monitoring, and data collection from meters and sensors in energy management systems.

Facility and Infrastructure Control

In infrastructure automation (buildings, water treatment, HVAC), the BCU‑02 integrates multiple signal types to monitor environmental conditions, equipment status, and facility performance.

Product Advantages

Multi‑Signal Support

BCU‑02 handles a mix of digital inputs/outputs and analog inputs/outputs, providing flexibility for diverse field devices.

Modular and Expandable Design

Designed for modular integration, it can be combined with additional I/O or communication modules to scale system capability.

Industrial Robustness

Engineered to withstand electrical noise, vibration, and thermal stress typical of industrial environments.

Built‑In Diagnostics

LED indicators and status flags provide real‑time feedback on module health, signal status, and fault conditions, reducing troubleshooting time.

Reliable Communication

Supports secure and stable communication paths to controllers and remote units, enabling dependable data flow.

Technical Specifications

| Specification | Details |

|---|---|

| Model | BCU‑02 (3AUA0000110429) |

| Module Type | Control and Protection Interface Unit |

| Digital Inputs | 16 inputs |

| Digital Outputs | 8 outputs |

| Analog Inputs | 8 channels (voltage/current) |

| Analog Outputs | 4 channels (voltage/current) |

| Input Signal Types | Voltage: ±10 V, 0–10 V; Current: 4–20 mA, 0–20 mA |

| Output Signal Types | Voltage: 0–10 V; Current: 4–20 mA |

| Resolution | 16‑bit |

| Sampling Time | ~25 ms per channel |

| Power Consumption | 8.0 W |

| Operating Temperature | –20°C to +60°C |

| Storage Temperature | –40°C to +85°C |

| Isolation | Channel‑to‑system isolation |

| Dimensions (H×W×D) | 120 mm × 160 mm × 60 mm |

| Weight (kg) | 1.40 kg |

| Mounting Method | DIN rail / Modular rack |

| Status Indicators | Power, I/O, and fault LEDs |

Related Models — Same Series or Similar Function

| Model | Digital Inputs | Digital Outputs | Analog Inputs | Analog Outputs | Power (W) | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|

| BCU‑01 | 8 | 4 | 4 | 2 | 5.0 | 100 × 140 × 55 | 0.95 |

| BCU‑03 | 24 | 12 | 12 | 6 | 10.0 | 140 × 170 × 65 | 1.60 |

| BCU‑05 | 32 | 16 | 16 | 8 | 12.0 | 150 × 180 × 70 | 1.95 |

| BCU‑10 | 16 | 16 | 8 | 8 | 9.0 | 130 × 160 × 60 | 1.45 |

| BCU‑20 | 32 | 32 | 16 | 16 | 14.0 | 180 × 200 × 75 | 2.30 |

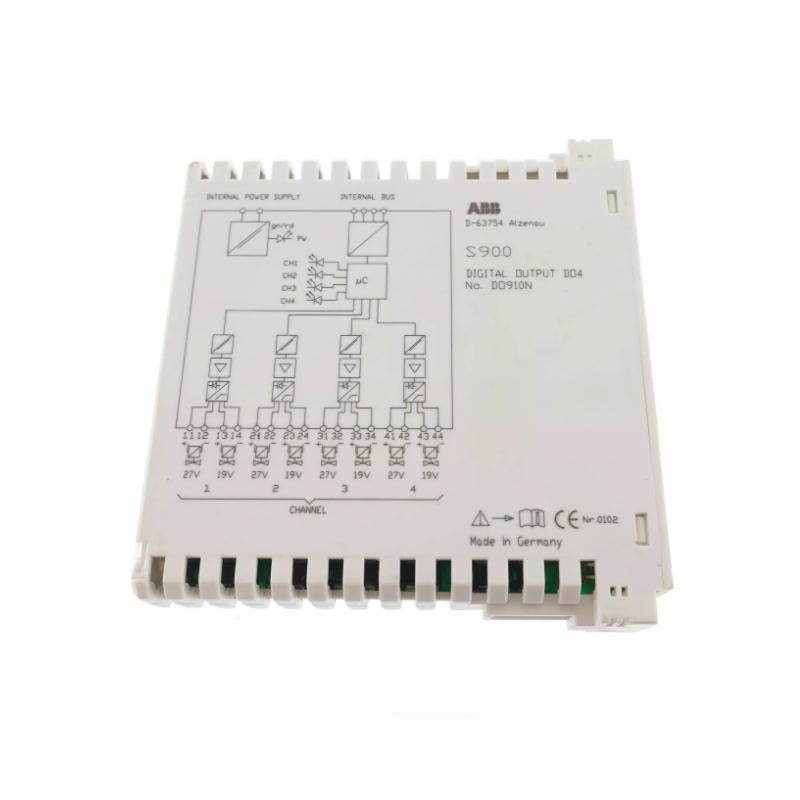

Other Popular Models — Same Brand

| Model | Function | Channels/Outputs | Resolution/Type | Power (W) | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| DI810 | Digital Input Module | 16 digital inputs | Digital | 2.0 | 90 × 120 × 25 | 0.32 |

| DO810 | Digital Output Module | 16 digital outputs | Digital | 2.0 | 90 × 120 × 25 | 0.33 |

| AO820 | Analog Output Module | 16 analog outputs | 16‑bit | 3.0 | 90 × 120 × 40 | 0.50 |

| AI880 | Analog Input Extended Range | 8 analog inputs | 16‑bit | 2.0 | 90 × 120 × 30 | 0.35 |

| CI840 | Communication Interface Module | Network interface | Fieldbus / Ethernet | 3.5 | 90 × 120 × 40 | 0.60 |

Frequently Asked Questions (FAQ)

Q1: What is the main function of BCU‑02?

A1: BCU‑02 is an interface and control unit that acquires analog/digital signals, conditions them, performs logic functions, and communicates data to controllers.

Q2: How many digital inputs are supported?

A2: BCU‑02 supports 16 digital input channels.

Q3: How many analog input channels are provided?

A3: The module provides 8 analog input channels.

Q4: How many analog output channels does BCU‑02 have?

A4: It offers 4 analog output channels.

Q5: What is the resolution of the analog signals?

A5: The analog channels use 16‑bit resolution for accurate data conversion.

Q6: What are the dimensions of the BCU‑02?

A6: The dimensions are 120 mm × 160 mm × 60 mm.

Q7: What is the approximate weight of the unit?

A7: BCU‑02 weighs about 1.40 kg.

Q8: What environments is BCU‑02 designed for?

A8: It is designed for industrial environments with electrical noise, temperature variations, and vibration.

Q9: Does the module offer diagnostics?

A9: Yes, LED indicators display power status, I/O activity, and fault conditions.

Q10: Can BCU‑02 be integrated into larger automation systems?

A10: Yes, its modular design allows integration with other units for scalable control systems.