ProductPRODUCT

Featured products

Contact Us

- GE

- IS215REBFH1BA

- Turbine Control Board Expansion Board

- USA

- 335 mm × 175 mm × 35 mm

- 0.56kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 127

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Basic Information

-

Brand: GE

-

Series: Mark VI / Speedtronic Industrial Control Series

-

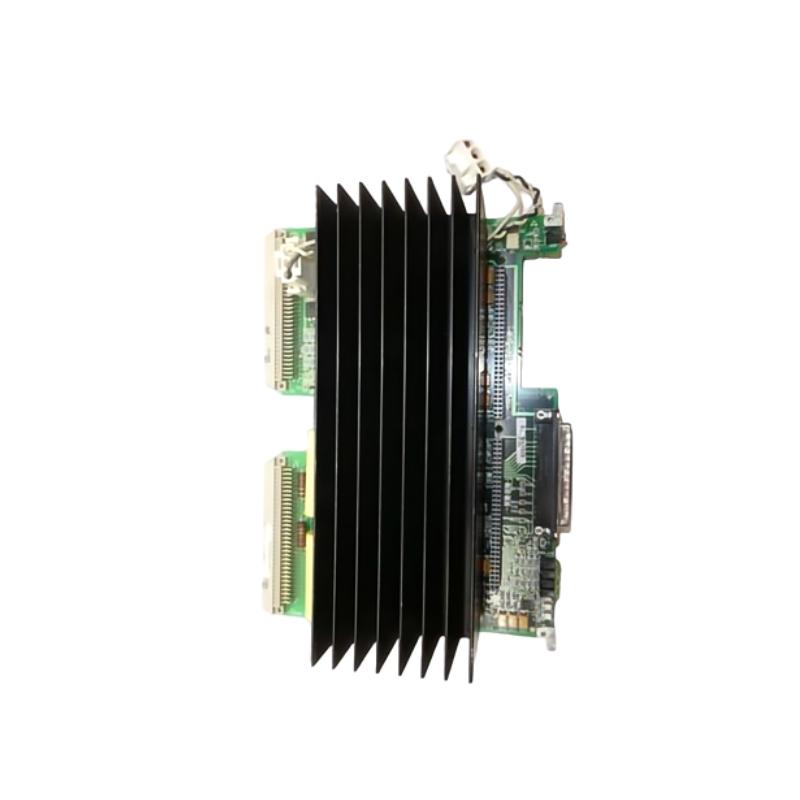

Model: IS215REBFH1BA

-

Product Type: Turbine Control Board / Module (Relay‑Output Control Module)

Technical Specifications

| Parameter | Description |

|---|---|

| Model | IS215REBFH1BA |

| Brand | GE |

| Series | Mark VI / Speedtronic |

| Product Type | Turbine Control Board / Relay‑Output Module |

| Dimensions | 335 mm × 175 mm × 35 mm (≈ 33.5 cm × 17.5 cm × 3.5 cm) |

| Weight | 0.56 kg (approx.) |

| Operating Voltage | 24 V DC nominal |

| Operating Temperature | ‑20 °C to +70 °C (storage ‑40 °C to +85 °C) |

| Communication | RS‑232 / RS‑485 interfaces |

| I/O Points | 16 inputs, 8 outputs (relay outputs) |

| Humidity Range | 5 % to 95 % non‑condensing |

| Certifications | UL, CE, CSA |

Product Description

The IS215REBFH1BA is a high‑performance control board designed for turbine control systems and other industrial automation environments. It is part of the Mark VI series of modules, and functions primarily to provide relay‑output control, signal acquisition and distribution, and interface operations within a larger control rack system.

Its architecture is built for reliability and robustness. With 16 digital inputs and 8 relay outputs, it can manage critical signal switching tasks such as motor drives, valve actuation, alarms or auxiliary control loops. The board’s compact dimensions and light weight make it easy to install as a spare or replacement module. It supports standard industrial communication (RS‑232 / RS‑485) and is engineered for harsh environments.

The module is often used in power‑generation plants (gas turbines, steam turbines) or large process automation installations. It integrates with larger control systems, enabling rapid signal processing and reliable output switching, and helps ensure that critical processes remain under control with minimal downtime risk.

Applications

-

Turbine control systems (gas or steam turbines) where relay outputs drive auxiliary components such as trip solenoids, valves, alarms.

-

Industrial process automation where reliable relay switching is required in harsh conditions (temperature, vibration, humidity).

-

Function as an I/O expansion or interface module within Mark VI control racks, enabling system upgrades or spares replacement.

-

Control panels in power generation: providing discrete signal handling and output switching for auxiliary turbine systems.

-

Retrofit or spare part for existing Mark VI control architecture where original modules are aged or obsolete.

Product Advantages

-

Compact and lightweight: With dimensions of approximately 335 × 175 × 35 mm and weight of only ~0.56 kg, installation and replacement are simplified.

-

High reliability: Designed for extended industrial operating ranges (‑20 °C to +70 °C), non‑condensing humidity, robust design for control environments.

-

Standard communication interfaces: RS‑232 and RS‑485 enable easy integration with existing control systems without need for major redesign.

-

Flexible I/O capacity: 16 digital inputs and 8 relay outputs allow for comprehensive auxiliary control in turbine or process systems.

-

Easy system integration: Compatible with Mark VI series racks and architecture, making it suitable for replacement, upgrade or system extension.

-

Rapid deployment as spare: Light weight and standardized format facilitate fast change‑out in critical power generation or industrial environments.

-

Lower maintenance downtime: By being a drop‑in module with known specification and high reliability, downtime for repair or replacement is minimized.

-

Longevity and serviceability: Built with industrial‑grade components and standardized interface, this board supports long term service life in demanding applications.

Related Models (Same Series / Related)

Here are five models that belong to the same series or are directly related, with key specification highlights:

| Model | Description | Key Specifications (Dimensions / Weight) |

|---|---|---|

| IS215REBFH1BA | Current product: turbine control board with relay outputs | 335 × 175 × 35 mm / ~0.56 kg |

| IS215REBFH1A | Earlier version of the circuit board with similar function | ~330 × 178 × 20 mm / ~0.5 kg |

| IS215REBFH1BB | Variant in the same series with enhanced I/O or revision | ~330 × 178 × 20 mm / ~0.6 kg |

| IS215REBGH1BA | Control board specializing in analog/digital I/O interface | ~330 × 100 × 200 mm / ~2.0 kg |

| IS215REBFH2BA | Next‑generation in the “REBFH” family with higher capacity | ~335 × 175 × 35 mm / ~0.7 kg |

Popular Models from the Same Brand

Below are five other popular modules from GE used in turbine or industrial control systems:

| Model | Description | Key Specifications (Dimensions / Weight) |

|---|---|---|

| IS215WEPAH2AB | Turbine pitch axis control module | 200 × 150 × 50 mm / ~1.2 kg |

| IS200AEPAH1ACB | Power supply / control interface module | 100 × 150 × 50 mm / ~0.8 kg |

| IS215VCMH2B | Communication / monitoring module (VME architecture) | ~258 × 160 × 40 mm / ~1.9 kg |

| IS215PMVPH1AA | Processor control board for turbine logic | 330 × 100 × 200 mm / ~2.0 kg |

| IS215UCVEM06A | Universal control module / VME card | 159 × 178 × ~? mm / ~1.0 kg |

FAQ (Frequently Asked Questions)

Q1: What is the primary function of the IS215REBFH1BA board?

A1: It is a relay‑output control board intended for turbine or process control systems, providing discrete inputs and relay outputs to command auxiliary devices such as valves, motors or alarms.

Q2: Which series does this board belong to?

A2: It belongs to the GE Mark VI / Speedtronic control system series.

Q3: What are its dimensions and weight?

A3: The dimensions are approximately 335 × 175 × 35 mm and the weight is about 0.56 kg.

Q4: What input voltage does it use?

A4: It uses a nominal 24 V DC power supply.

Q5: What is its operating temperature range?

A5: The typical operating temperature range is from ‑20 °C to +70 °C, with storage conditions to ‑40 °C to +85 °C.

Q6: How many I/O channels does it support?

A6: It supports 16 digital inputs and 8 relay outputs.

Q7: What communication interfaces are available?

A7: It supports RS‑232 and RS‑485 serial communication interfaces for integration with control systems.

Q8: Is it suitable for high‑risk or industrial turbine environments?

A8: Yes, it is designed for industrial automation and power generation environments with rigorous reliability requirements.

Q9: How easy is it to replace or retrofit this board?

A9: It is relatively easy because it uses standard form factor, standardized connections, and is compatible with the Mark VI system. Proper slot, wiring and system compatibility must be verified.

Q10: What should be checked before ordering this board?

A10: You should verify the exact model number and revision (IS215REBFH1BA), check compatibility with your control rack/backplane, confirm the voltage and I/O requirements, and ensure the environment (temperature, vibration) is within specifications.