ProductPRODUCT

Featured products

Contact Us

- ABB

- SDCS-PIN-205

- Power Interface Board Driver Board

- Sweden

- 203 mm × 635 mm × 330 mm

- 3kg

- 3ADT310500R1

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 132

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Product Overview

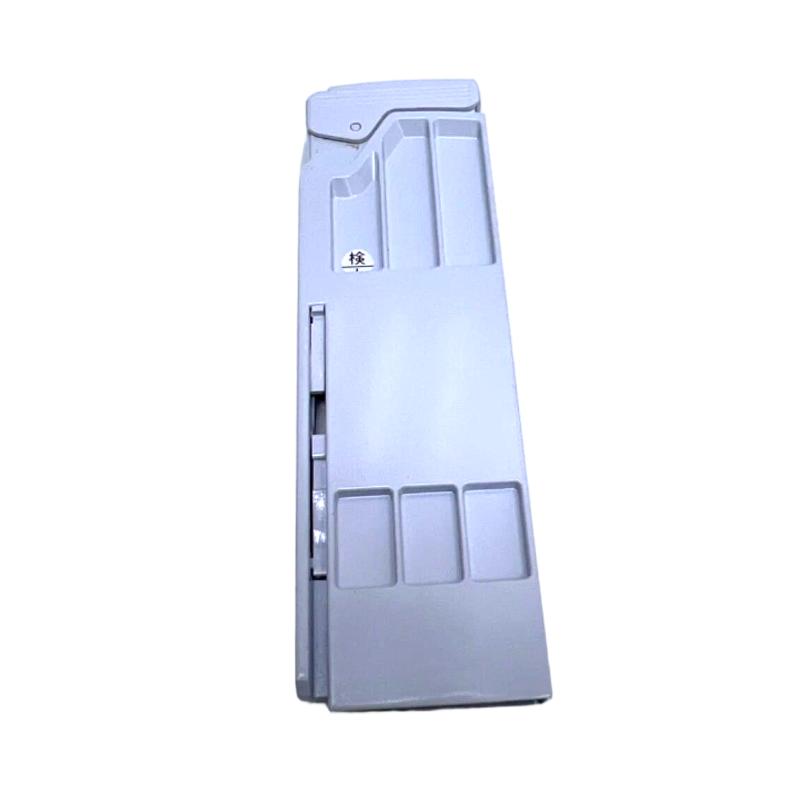

The ABB SDCS‑PIN‑205 (Part No. 3ADT310500R1) is a Power Interface Board designed for ABB’s DCS (Drive Control System) modular architecture. It serves as the interface board between high‑power converter modules and the control electronics in industrial drive systems. This board handles power routing, signal interface, measurement of armature current/voltage, snubber circuits and protects the converter interface in large DC/AC drive systems.

This module is used where modular drive replacement or retrofit is required, especially in heavy‑industrial settings. By using a standard board like the PIN‑205, engineers can replace or service the interface portion of the drive without replacing the entire converter, reducing cost and downtime.

Product Parameters

| Parameter | Description |

|---|---|

| Model | SDCS‑PIN‑205 |

| Part Number | 3ADT310500R1 |

| Product Type | Power Interface Board (Converter Interface Card) |

| Brand | ABB |

| Series | DCS Control System Series — PIN family |

| Rated Operational Use | For converter modules (DCS series) with armature/field ratings e.g. up to 500 V DC, various currents |

| Dimensions (W × H × D) | 203 mm × 635 mm × 330 mm (as one listing) |

| Weight (kg) | Approximately 3.0 kg (as given) |

| Operating Temperature | –25 °C to +60 °C (per one specification) |

| Mounting | Panel‑mount / module rack installation |

| Typical Role | Interface of high‑power converter to control electronics: measurement, snubber, protection circuits |

Product Description

The SDCS‑PIN‑205 board is engineered to function as the interface card within a large modular drive system. In a DCS cabinet, the power converter (thyristor or IGBT modules) require interface boards that connect the high‑voltage and high‑current part of the converter to the control side. This includes circuits for armature current measurement, voltage measurement, zero‑current detection, snubber networks (RC or RCD) for thyristors, and protection fuses.

The PIN‑205 board allows standardisation of the interface portion, making service and spare‑board replacement simpler. Because it deals with power interface and high‑voltage/ high‑current circuits, its form factor is larger (203 × 635 × 330 mm) and heavier (~3 kg) compared to typical logic or I/O boards. In practice, when a drive experiences a failure in the interface section, an engineer can remove the PIN‑205 board and replace with a spare without replacing the full converter stack.

The board supports various converter sizes, depending on system design, and often is used in retrofit or spare‑parts strategies in heavy industry: steel mills, large hoists, mining drives etc. It ensures that signal conditioning, measurement, snubber circuits and protection are all integrated in a standard module.

Product Applications

-

Large DC or AC motor drives in steelmaking, rolling mills and heavy industry where modular DCS architectures are used.

-

Conveyor systems, mining hoists, ship propulsion drives requiring high‑power interface boards for serviceability.

-

Retrofitting older drive systems (DCS500, DCS600 series) where interface card replacement is needed.

-

Service spare‑board strategy in drive control rooms: stocking the PIN‑205 simplifies field replacements.

-

Drive systems in power generation or utility environments where high reliability and modular repair are required.

-

Control cabinets where modular drive parts allow for quick swapping of interface cards rather than full drive sections.

-

Environments with heavy duty usage, where high current, high voltage and high reliability are required for decades of service.

Product Advantages

-

Modular Serviceability – Replace only the interface board rather than the entire drive unit, reducing downtime and cost.

-

Standardised Module – Form‑factor and interface consistent across converter sizes, simplifying spares management.

-

Robust Design for Power Circuits – Built to handle snubbers, measurement circuits and protection in converter interface sections.

-

Large Module for Heavy‑Duty Use – Dimensions and weight reflect its heavy‑duty role, suited for industrial drives.

-

Simplified Maintenance Strategy – Keeping standard interface boards in stock enables faster field repair turnaround.

-

Compatibility with DCS Architecture – Designed specifically for ABB’s DCS modular drive systems, ensuring integration.

-

Cost‑Efficient Upgrade Path – When converting or upgrading drive cabinets, replacing just the interface board is often sufficient.

-

Designed for Industrial Environment – Operational temperature range, high‑voltage isolation, durable build suited for harsh conditions.

Brand Information

Brand: ABB

ABB is a global leader in power and automation technologies. Its DCS drive systems are widely used in heavy industrial applications. The SDCS series (Control System Series) is a key part of ABB’s modular drive and automation offering, and the PIN family (power interface boards) plays a critical role in converter control reliability and serviceability.

Product Series

Series: DCS Control System Series – PIN Family

In ABB’s modular architecture, the series includes categories: control boards (CON), I/O interface boards (IOB), I/O expansion boards (IOE), power interface boards (PIN), excitation boards (FEX) and more. The SDCS‑PIN‑205 is part of the PIN family, intended for power/converter interface roles.

Recommended Models

Same Series / Related Models

| Model | Description | Key Parameters |

|---|---|---|

| SDCS‑PIN‑205B | Variant “B” version of interface board | Weight ~0.5 kg (earlier listing variant) |

| SDCS‑PIN‑22 | Interface board for 450 A / 520 A converter at 500 V | Dimensions ~175 × 87 × 43 mm; Weight ~0.64 kg |

| SDCS‑PIN‑24 | Interface board for 450 A at 600 V converter | Higher rating version |

| SDCS‑PIN‑4 | Earlier interface board version | Weight ~0.91 kg; typical for smaller converter |

| SDCS‑POW‑1 | Power supply board of same modular family | Dimensions ~160 × 120 × 80 mm; Weight ~1.5 kg |

Popular Models (Same Brand)

| Model | Description | Key Parameters |

|---|---|---|

| ACS880‑01‑097A‑3 | High‑performance AC drive module | ~75 kW; 400 V; ~55 kg |

| DCS800‑S02‑0160‑05 | High‑capacity DC drive system | ~160 A; 500 V; ~48 kg |

| CI858A | Communication interface module | 24 V DC logic; ~0.50 kg |

| PM865K01 | Processor/control board module | 24 V DC logic; ~0.55 kg |

| DSQC1047 | Automation control board | 24 V DC logic; ~0.70 kg |

FAQ (Frequently Asked Questions)

Q1: What is the primary role of the SDCS‑PIN‑205 board?

A1: It acts as the power interface board inside an ABB DCS modular drive system, interfacing the high‑power converter modules to the control electronics.

Q2: What are the physical dimensions and weight of the board?

A2: The board is approximately 203 mm × 635 mm × 330 mm in size, and weighs around 3.0 kg.

Q3: What converter ratings does this board support?

A3: It is used for converter modules within the DCS series; typical usage includes systems up to 500 V DC with various current ratings.

Q4: What is the operating temperature range for the module?

A4: The board is specified to operate from –25 °C up to +60 °C under typical industrial drive cabinet conditions.

Q5: In what type of applications is the PIN‑205 used?

A5: Heavy‑duty industrial drive systems such as steel mills, mining drives, large conveyors or marine propulsion systems.

Q6: What advantage does standardising on a board like PIN‑205 provide?

A6: It simplifies maintenance and spare‑board strategy—engineers can stock the interface board and swap quickly rather than replacing the entire converter.

Q7: Is the board suitable for retrofitting older drives?

A7: Yes — since it is part of the modular architecture, it can be used in retrofit installations of drives in the ABB DCS family.

Q8: How does replacement of the interface board impact downtime?

A8: Because only the interface board is replaced rather than the full drive unit, downtime and cost are significantly reduced.

Q9: Does the board handle measurement functions as well?

A9: Yes — it typically includes circuitry for armature current and voltage measurement, snubber networks and zero‑current detection relevant to converter modules.

Q10: Why is the weight and size larger compared to regular I/O boards?

A10: Because the board handles high‑power interface duties, the board must accommodate snubber networks, measurement circuits, high‑voltage insulation and heavier copper paths, hence larger size and weight.