ProductPRODUCT

Featured products

Contact Us

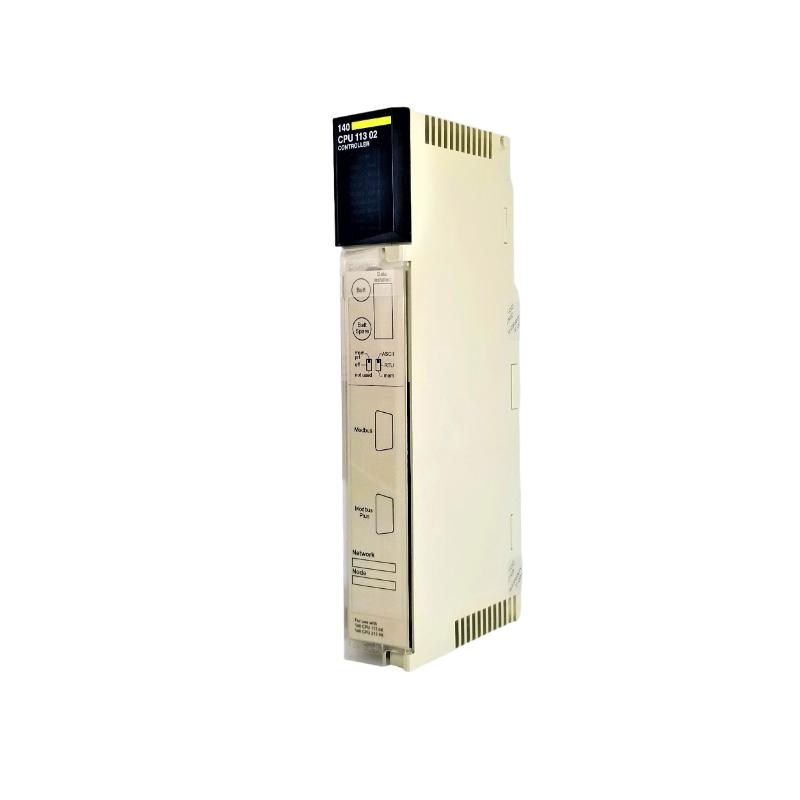

- Schneider Electric

- 140CPU11302C

- Processor 80186 Modicon Quantum

- France

- 120 mm x 130 mm x 90 mm

- 0.6kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 57

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Product Overview: Schneider Electric 140CPU11302C

Introduction to the Product

The Schneider Electric 140CPU11302C is a high-performance programmable logic controller (PLC) designed for a wide range of industrial automation and control applications. As part of the Modicon series, this model combines cutting-edge technology with robust reliability, ensuring seamless performance in demanding industrial environments. Whether used in manufacturing, energy management, or building automation, the 140CPU11302C delivers superior control capabilities with scalability and flexibility.

This PLC is built to handle complex control tasks with minimal latency, making it ideal for real-time data processing and advanced system monitoring. The 140CPU11302C integrates seamlessly with other automation systems, providing an ideal solution for users who need flexibility and performance in a compact design.

Product Applications

The 140CPU11302C is suitable for a variety of applications, including:

-

Manufacturing Automation: It is ideal for controlling assembly lines, robotic arms, conveyors, and packaging systems, allowing for efficient and precise operations.

-

Energy Management: The PLC can be used to monitor and control power consumption, ensuring energy efficiency in industrial and commercial facilities.

-

Water and Wastewater Treatment: This model is used to control pumps, valves, filtration systems, and chemical dosing processes in water treatment plants.

-

Building Automation: The 140CPU11302C is also utilized to manage HVAC systems, lighting, and access control in smart building systems.

-

Process Control: Industries like food and beverage, pharmaceuticals, and chemical processing rely on the 140CPU11302C for precise control over production processes.

Advantages of the Product

The 140CPU11302C offers a number of distinct advantages:

-

High-Speed Processing: With an advanced processor, the PLC can execute complex logic and real-time control tasks with minimal delay.

-

Scalability and Flexibility: This PLC supports a wide range of I/O modules, allowing users to easily expand and customize their system as needed.

-

Robust Communication Options: The 140CPU11302C features multiple communication ports, including Ethernet and USB, for easy integration with other devices and systems.

-

Reliability: Designed for use in industrial environments, it offers long-term performance and durability, minimizing the risk of downtime.

-

Energy Efficiency: The PLC enables real-time monitoring of energy consumption, helping industries optimize their energy usage and reduce costs.

-

Ease of Use: The product is supported by Schneider Electric’s EcoStruxure Control Expert software, which simplifies the programming and configuration of automation tasks.

Brand: Schneider Electric

Schneider Electric is a global leader in energy management and automation solutions. The company offers a comprehensive range of products that improve energy efficiency, automation, and sustainability across various industries. The 140CPU11302C is part of Schneider Electric’s Modicon series of PLCs, which are trusted by industries worldwide for their performance, scalability, and reliability.

Product Series: Modicon

The 140CPU11302C is part of the Modicon series, which has long been a benchmark in programmable logic control. The Modicon PLCs are known for their flexibility, modularity, and support for complex automation tasks. These PLCs are widely used in industries such as manufacturing, energy, water treatment, and process control, offering solutions that meet the diverse needs of industrial automation.

Product Specifications

Here is a table summarizing the key specifications of the Schneider Electric 140CPU11302C:

| Parameter | Specification |

|---|---|

| Model | 140CPU11302C |

| Type | Programmable Logic Controller (PLC) |

| Series | Modicon |

| Input Voltage | 24V DC |

| Output Voltage | 24V DC |

| Operating Temperature | -20°C to 60°C |

| Storage Temperature | -40°C to 85°C |

| Dimensions (L x W x H) | 120 mm x 130 mm x 90 mm |

| Weight | 0.6 kg |

| Mounting Type | DIN Rail |

| Communication Ports | 1 x Ethernet, 1 x USB |

| I/O Modules Supported | Up to 16 Digital/Analog Modules |

| Programming Language | Ladder Logic, Function Block, Structured Text |

| Protection | IP20 (Ingress Protection) |

| Certification | CE, UL, cULus |

| Status Indicators | LEDs (Power, Communication, Fault) |

| Warranty | 1 Year |

Recommended Products from the Same Series or Related Models

Here are five additional models from the Modicon series or similar related models:

| Model | Specification |

|---|---|

| Modicon 140CPU11303 | 24V DC, 3 communication ports, 10 Digital I/O, Ethernet, 2 x USB |

| Modicon 140CRA31200 | Analog I/O modules, 8 analog inputs, 2 outputs |

| Modicon 140DRA84000 | 24V DC, 16 digital relay outputs |

| Modicon 140CPS11400 | 24V DC, 16 digital I/O, Ethernet communication, modular design |

| Modicon 140CPU65150 | Advanced CPU, supports EtherNet/IP, CANopen, Modbus TCP |

Recommended Popular Models from Schneider Electric

Here are five other popular models from Schneider Electric that are widely used across various industries:

| Model | Specification |

|---|---|

| Schneider 140DTA86400 | 24V DC, 16 digital inputs, 16 relay outputs, compact design |

| Schneider 140XBP93100 | Expansion module, 24V DC, 8 analog inputs, 4 outputs |

| Schneider 140ACO77100 | Analog input/output, 8 channels for industrial applications |

| Schneider 170STP10000 | Motion control system, 2 communication ports, high precision |

| Schneider 2210SM7 | Smart relay module, 16 inputs, 8 outputs for small automation tasks |

Frequently Asked Questions (FAQ) about the 140CPU11302C

Q1: What is the primary function of the 140CPU11302C?

A1: The 140CPU11302C is a programmable logic controller (PLC) used to automate and control industrial processes, machinery, and equipment. It provides real-time control, monitoring, and data processing for a wide range of applications.

Q2: What are the main advantages of using the 140CPU11302C in automation systems?

A2: The key advantages include its high-speed processing capabilities, modular design for easy expansion, reliable communication ports for seamless integration, and ease of use with Schneider Electric’s EcoStruxure Control Expert software.

Q3: How many I/O modules can the 140CPU11302C support?

A3: The 140CPU11302C supports up to 16 digital and analog I/O modules, making it highly customizable for various applications.

Q4: What programming languages can be used with the 140CPU11302C?

A4: The PLC can be programmed using Ladder Logic, Function Block Diagram (FBD), and Structured Text (ST), providing flexibility for users with different programming preferences.

Q5: What communication protocols are supported by the 140CPU11302C?

A5: The 140CPU11302C supports Ethernet and USB communication, enabling easy integration with other systems and devices for data exchange and monitoring.

Q6: What is the operating temperature range of the 140CPU11302C?

A6: The 140CPU11302C operates in temperatures ranging from -20°C to 60°C, making it suitable for a variety of industrial environments.

Q7: How is the 140CPU11302C mounted?

A7: The 140CPU11302C is designed to be mounted on a DIN rail, which simplifies installation in control cabinets and other industrial settings.

Q8: Does the 140CPU11302C support remote monitoring and control?

A8: Yes, the 140CPU11302C can be integrated into a remote monitoring and control system using its Ethernet port, allowing operators to access real-time data and control operations from a central location.

Q9: What certifications does the 140CPU11302C have?

A9: The 140CPU11302C is certified with CE, UL, and cULus certifications, ensuring it meets global safety and performance standards.

Q10: What is the warranty period for the 140CPU11302C?

A10: The 140CPU11302C comes with a 1-year warranty, which covers any manufacturing defects or issues with the product under normal operating conditions.