ProductPRODUCT

Featured products

Contact Us

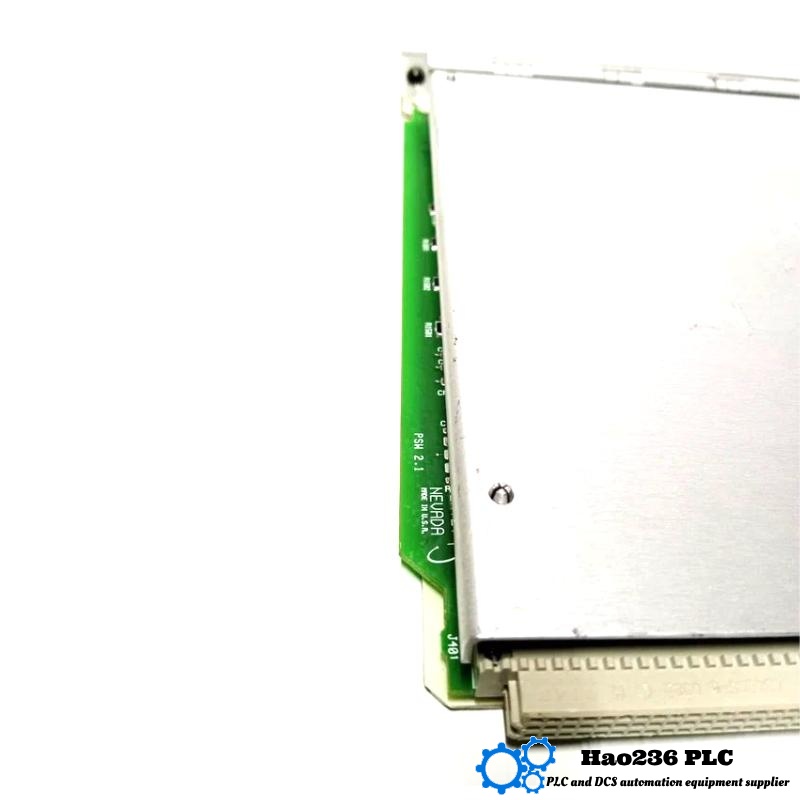

- Bently Nevada

- 3500/72 176449-08

- Recip Impulse Velocity Monitor

- USA

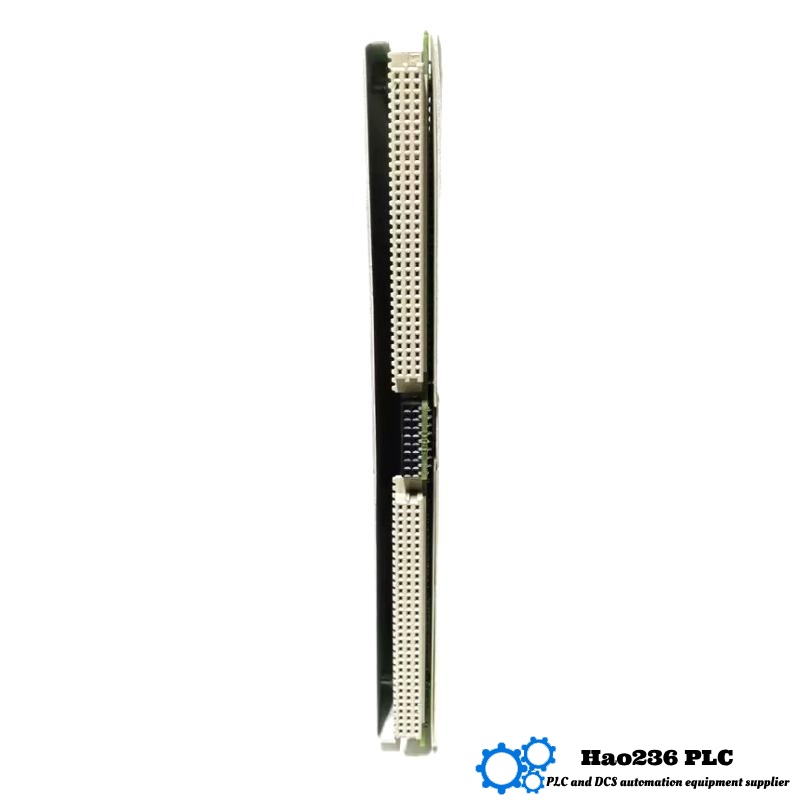

- 241.3 mm × 24.4 mm × 241.8 mm

- 0.91kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 38

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| sales@plc-automations.com | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Bently Nevada 3500/72M 176449-08

Product Introduction

The Bently Nevada 3500/72M 176449-08 is a high-performance proximity/seismic monitor module designed for precise monitoring of reciprocating machinery. It is an integral component of the 3500 Series Machinery Protection System, offering advanced capabilities for detecting and analyzing mechanical issues in critical equipment. This module provides real-time monitoring of rod position and drop, enabling early detection of potential failures and facilitating predictive maintenance strategies.

Applications

The 3500/72M 176449-08 is widely utilized in various industries where reciprocating machinery is prevalent, including:

-

Gas Compression Stations: Ensures reliable performance of reciprocating compressors by detecting mechanical degradation in rods and crossheads.

-

Petrochemical Plants: Critical for avoiding unplanned outages due to component wear in reciprocating compressors.

-

Oil Refineries: Monitors key machinery operating under continuous stress in refining operations.

-

LNG Processing Facilities: Supports real-time diagnostics and condition monitoring of reciprocating equipment.

-

Industrial Manufacturing: Enhances mechanical asset longevity through precision rod movement monitoring.

-

Pipeline Transmission Systems: Ensures compressor stations remain operational with early fault detection.

Advantages

-

Dual Measurement Capability: Monitors both rod drop and rod position, delivering comprehensive analysis of mechanical health.

-

Advanced Firmware (176449-08): Provides higher accuracy, resolution, and processing speed compared to earlier models.

-

Buffered and 4–20 mA Outputs: Enables easy integration with DCS, PLCs, and vibration analysis tools.

-

High Compatibility: Seamless use with Bently Nevada 3300 XL proximity transducers.

-

Early Fault Detection: Alerts for misalignment, wear, and crosshead damage before failure occurs.

-

Redundant System Support: Works in critical redundancy configurations for fault-tolerant designs.

-

Compact Rack Integration: Occupies minimal rack space while monitoring two independent channels.

-

Environmentally Hardened: Designed for EMI-resistance and harsh operating conditions.

-

Hot-Swappable: Module can be replaced without shutting down the rack or system.

-

Maintenance Optimization: Enables predictive maintenance, extending compressor life and minimizing downtime.

Brand and Series

-

Brand: Bently Nevada

-

Series: 3500 Series (Machinery Protection System)

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 3500/72M 176449-08 |

| Measurement Type | Proximity/Seismic |

| Number of Channels | 2 |

| Input Signal | Proximity transducer signals for rod position measurement |

| Output | 4–20 mA analog for process control systems |

| Measurement Range | Configurable based on rod travel and machine requirements |

| Accuracy | ±0.25% of full-scale reading |

| Power Supply | Derived from the 3500 rack power supply |

| Operating Temperature | -30°C to +65°C |

| Compliance Standards | API 618 and ISO 10816 for reciprocating machinery |

| Dimensions (L×W×H) | 241.3 mm × 24.4 mm × 241.8 mm |

| Weight | 0.91 kg |

Recommended Related Models

| Model | Description | Channels | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|

| 3500/72M 176449-05 | Velocity Monitoring Module (Non-Modified) | 4 | 241.3 × 24.4 × 241.8 | 0.91 |

| 3500/42M 140471-01 | Proximity/Seismic Input Module | 8 | 160 × 110 × 250 | 1.5 |

| 3500/55 145988-02 | Speed Monitoring Module | 4 | 241 × 24 × 241 | 0.9 |

| 3500/64 176449-05 | Seismic Velocity Monitor | 4 | 241 × 24 × 241 | 0.92 |

| 3500/92 140471-01 | Communication Gateway Module | N/A | 160 × 110 × 250 | 1.2 |

Recommended Popular Models from the Same Brand

| Model | Description | Channels | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|

| 3500/22 140471-01 | Vibration Monitoring Module | 8 | 160 × 110 × 250 | 1.2 |

| 3500/55 140471-01 | Speed Monitoring Module | 4 | 160 × 110 × 250 | 1.3 |

| 3500/60 140471-01 | Temperature Monitoring Module | 16 | 160 × 110 × 250 | 1.6 |

| 3500/72M 140471-01 | I/O Module with External Terminations | 4 | 160 × 110 × 250 | 1.4 |

| 3500/90 140471-01 | System Controller Module | N/A | 160 × 110 × 250 | 1.4 |

Frequently Asked Questions (FAQs)

Q1: What types of machinery is the 3500/72M module best suited for?

A1: It is primarily designed for reciprocating machinery such as compressors and pumps, where rod position and drop monitoring is critical to avoid mechanical failures.

Q2: Can this module be integrated into existing 3500 Series racks?

A2: Yes, the 3500/72M is fully compatible with standard 3500 Series racks and can be hot-swapped without system downtime.

Q3: What is the typical operating temperature range for this module?

A3: The module operates reliably within -30°C to +65°C, suitable for most industrial environments.

Q4: How many channels does the 3500/72M support?

A4: It supports two independent channels, allowing simultaneous monitoring of multiple rod positions.

Q5: What output signals does the module provide?

A5: It provides industry-standard 4–20 mA analog outputs for integration with control systems and data acquisition.

Q6: Is the module resistant to electromagnetic interference (EMI)?

A6: Yes, the 3500/72M is designed with robust EMI shielding to ensure signal integrity in harsh industrial settings.

Q7: What are the benefits of using this module over traditional monitoring methods?

A7: It offers real-time monitoring with higher accuracy and early fault detection, reducing unplanned downtime and maintenance costs.

Q8: Does this module support redundant configurations?

A8: Yes, it supports redundant system setups for enhanced reliability and fault tolerance.

Q9: What are the physical dimensions and weight of the module?

A9: The module measures approximately 241.3 mm × 24.4 mm × 241.8 mm and weighs about 0.91 kg.

Q10: How does this module contribute to predictive maintenance programs?

A10: By providing early warnings on rod position deviations and potential mechanical issues, it enables timely interventions, extending equipment life and optimizing maintenance schedules.

Authenticity guarantee

All product specifications are original and authentic imported products. We have an annual sales volume of 300 million yuan, and we only produce original and authentic products. All customers who cooperate with us directly online can enjoy low discounts.

Free warehouse

We have a complete range of product models, 80% of conventional models are in stock, and we have established channels in Asia, Africa, North America, South America, and Europe, effectively shortening the order processing time and satisfying customers in a timely manner.

Technical Team

Fast delivery. Spot goods can be shipped on the same day, and the delivery time transaction is 20% faster than that of peers on average, with a delivery time accuracy rate of 99%.

Thoughtful after-sales service

24-hour after-sales service guarantee team, professional and standardized management service system.