ProductPRODUCT

Featured products

Contact Us

- Bently Nevada

- 3500/42

- Seismic Monitor

- USA

- 241.3 x 24.4 x 241.8 mm

- 0.91kg

- 140471-01+140734-02

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 106

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| sales@plc-automations.com | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

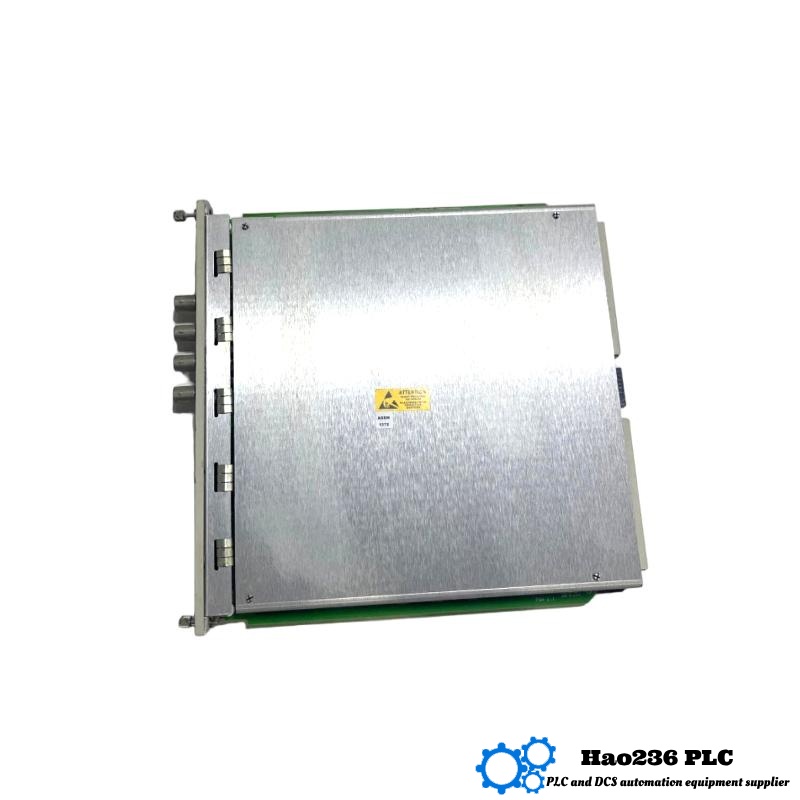

Bently Nevada 3500/42 140471-01 + 140734-02 Seismic Monitor

Product Introduction

The Bently Nevada 3500/42 Seismic Monitor, model 140471-01 + 140734-02, is an advanced monitoring device designed for detecting seismic activity and vibration in critical infrastructure, particularly in industrial and power generation systems. The 3500/42 Seismic Monitor helps prevent equipment failure by providing early warning of potentially damaging seismic events, such as vibrations or ground movements caused by machinery or external sources.

Part of the 3500 Series from Bently Nevada, this Seismic Monitor offers high-precision measurement and monitoring capabilities, enabling operators to take timely corrective actions. It is an essential tool for ensuring the safety and operational integrity of large, complex industrial systems, reducing the risk of costly downtime and potential catastrophic failures.

Product Parameters

| Parameter | Details |

|---|---|

| Dimensions | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Power Supply | 24 V DC |

| Communication | Bently Nevada System Communication |

| Mounting | Panel Mountable, DIN Rail Compatible |

| Seismic Measurement | Vibration Detection, Ground Movement |

| Operating Temperature | -40°C to 85°C |

| Signal Output | Analog, Digital |

| Calibration | Factory calibrated, Field Calibration available |

Product Application

The Bently Nevada 3500/42 Seismic Monitor is used in a variety of industries to monitor seismic activity, ensuring the safety and reliability of critical machinery. Key applications include:

-

Power Plants: Provides early detection of seismic events or vibrations that may affect turbine generators, transformers, or other sensitive equipment.

-

Oil & Gas: Monitors vibrations in drilling equipment, pressure vessels, and production systems to prevent equipment failures.

-

Industrial Manufacturing: Used to detect ground movement or machinery vibrations in factories, helping prevent damage to equipment and ensuring the safety of production lines.

-

Mining Operations: Monitors seismic activity to ensure the stability of machinery and prevent risks related to ground movement during mining operations.

-

Civil Engineering: Deployed in construction sites to monitor vibrations caused by equipment or external factors, ensuring that structures are not impacted.

Product Advantages

-

Early Detection: The seismic monitor provides early warning of vibrations or seismic activity, allowing operators to take timely action to prevent equipment failure.

-

High Precision: Capable of detecting even the smallest vibrations and ground movements, ensuring maximum protection for critical infrastructure.

-

Versatile Communication: Supports both analog and digital outputs, making it compatible with various control systems for ease of integration.

-

Wide Temperature Range: Designed to operate in harsh industrial environments with an operating temperature range of -40°C to 85°C.

-

Robust Design: Compact and durable design ensures reliability even in tough industrial conditions, with a mounting option for both panel and DIN rail installation.

-

Factory Calibration: The device is factory-calibrated, with field calibration options available, ensuring long-term accuracy.

Brand and Series

-

Brand: Bently Nevada

-

Series: 3500 Series – Machinery Protection and Condition Monitoring

The 3500 Series from Bently Nevada is a suite of products designed for monitoring and protecting critical machinery in industrial environments. The series includes vibration monitors, seismic monitors, and other condition monitoring solutions that help ensure the reliability, safety, and performance of high-value assets. The 3500/42 Seismic Monitor is part of this comprehensive suite, providing essential protection against vibrations and seismic events.

Recommended Related Models

Here are five related models from the Bently Nevada 3500 Series or similar seismic monitoring modules:

| Model | Description | Dimensions | Weight |

|---|---|---|---|

| 3500/45 | Vibration Monitor with Seismic Capabilities | 250 x 30 x 250 mm | 1.0 kg |

| 3500/47 | Rotating Machinery Monitor with Seismic Inputs | 280 x 35 x 270 mm | 1.2 kg |

| 3500/50 | Machinery Protection with Temperature & Seismic Monitoring | 260 x 40 x 260 mm | 1.1 kg |

| 3500/51 | Power Turbine Vibration & Seismic Monitor | 245 x 28 x 255 mm | 0.95 kg |

| 3500/52 | Advanced Vibration Monitoring for Industrial Equipment | 265 x 33 x 265 mm | 1.0 kg |

Popular Bently Nevada Models

Below are five other popular Bently Nevada models for machinery protection and condition monitoring:

| Model | Description | Dimensions | Weight |

|---|---|---|---|

| 3500/42 | Seismic and vibration monitoring module | 241.3 x 24.4 x 241.8 mm | 0.91 kg |

| 3500/20 | Vibration Monitoring for Rotating Equipment | 240 x 28 x 235 mm | 1.0 kg |

| 3500/23 | Accelerometer for Vibration Measurement | 200 x 25 x 200 mm | 0.75 kg |

| 3500/25 | Pressure Monitoring for Industrial Equipment | 220 x 30 x 230 mm | 0.85 kg |

| 3500/30 | Temperature Monitoring and Protection Module | 230 x 35 x 240 mm | 0.9 kg |

FAQs

-

Q: What is the purpose of the 3500/42 Seismic Monitor?

-

A: The 3500/42 is used for monitoring seismic activity and vibrations in critical machinery to prevent potential damage or failure.

-

-

Q: How does the Seismic Monitor detect vibrations?

-

A: It uses high-precision sensors that detect ground movements or vibrations in the machinery and surrounding environment.

-

-

Q: What communication protocols are supported by the 3500/42?

-

A: The 3500/42 supports both analog and digital outputs, allowing for easy integration with various control systems.

-

-

Q: Can the 3500/42 be used in outdoor environments?

-

A: Yes, the 3500/42 is designed to operate in a wide range of temperatures from -40°C to 85°C, making it suitable for harsh industrial environments.

-

-

Q: Is the 3500/42 Seismic Monitor easy to install?

-

A: Yes, it can be easily mounted on a DIN rail or in a panel, allowing for quick and secure installation.

-

-

Q: How is the 3500/42 calibrated?

-

A: The device comes factory calibrated, with options for field calibration available if needed.

-

-

Q: How does the seismic monitor help with preventive maintenance?

-

A: The monitor detects early signs of potential seismic events or vibrations, allowing maintenance teams to take corrective actions before damage occurs.

-

-

Q: What is the weight of the 3500/42 Seismic Monitor?

-

A: The weight of the module is 0.91 kg.

-

-

Q: Can the seismic monitor detect vibrations from external sources?

-

A: Yes, the 3500/42 is capable of detecting vibrations caused by both internal machinery and external seismic sources.

-

-

Q: What types of equipment can be monitored using the 3500/42?

-

A: The 3500/42 is used to monitor a wide range of critical machinery such as turbines, generators, pressure vessels, and other industrial systems.

-

Authenticity guarantee

All product specifications are original and authentic imported products. We have an annual sales volume of 300 million yuan, and we only produce original and authentic products. All customers who cooperate with us directly online can enjoy low discounts.

Free warehouse

We have a complete range of product models, 80% of conventional models are in stock, and we have established channels in Asia, Africa, North America, South America, and Europe, effectively shortening the order processing time and satisfying customers in a timely manner.

Technical Team

Fast delivery. Spot goods can be shipped on the same day, and the delivery time transaction is 20% faster than that of peers on average, with a delivery time accuracy rate of 99%.

Thoughtful after-sales service

24-hour after-sales service guarantee team, professional and standardized management service system.