ProductPRODUCT

Featured products

Contact Us

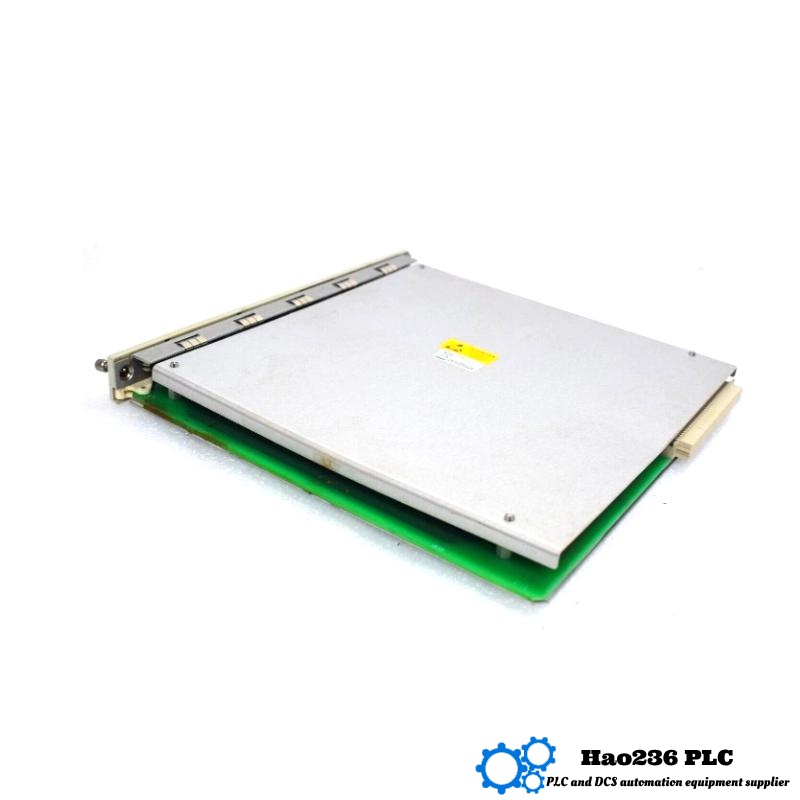

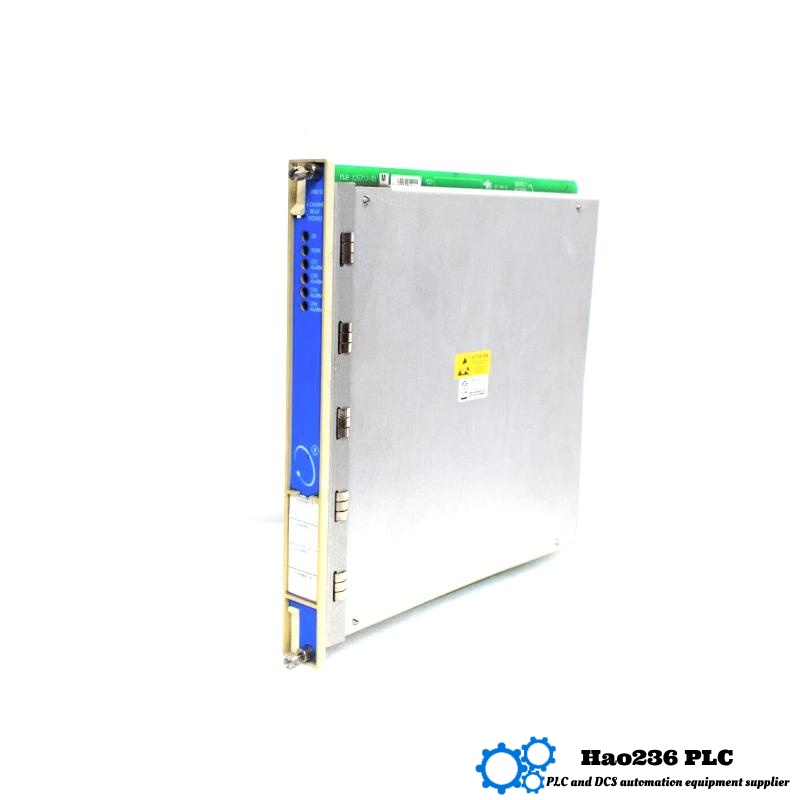

- Bently Nevada

- 3500/32 149986-02+125720-02

- 4-Channel Relay Module

- 280 mm x 170 mm x 60 mm

- 1.6kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 97

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Product Overview: Bently Nevada 3500/32 149986-02 + 125720-02

Product Introduction:

The Bently Nevada 3500/32 149986-02 + 125720-02 is an advanced vibration, displacement, and position monitoring system designed for continuous protection and performance monitoring of critical machinery in industrial environments. Part of the highly regarded 3500 Series, this system helps businesses in diverse industries protect their equipment, minimize downtime, and reduce the costs associated with maintenance and repairs.

This product is engineered to monitor turbines, compressors, motors, pumps, and other critical rotating machinery by continuously tracking their vibration patterns and position data. The system provides real-time insights that enable predictive maintenance, helping operators detect early signs of wear or potential failure before they lead to catastrophic damage.

Product Features:

-

Real-Time Monitoring: Continuously monitors key machinery parameters to ensure they are operating within safe limits.

-

Advanced Diagnostics: The 3500/32 offers diagnostic capabilities that allow operators to detect anomalies and predict future failures.

-

Scalability: The system can be expanded to accommodate multiple machines, making it suitable for both small-scale operations and large industrial plants.

-

Ease of Installation and Operation: The system is designed for straightforward installation, reducing setup time and minimizing training requirements for operators.

-

Flexible Communication: The 3500/32 supports various communication protocols like Modbus, Profibus, and Ethernet, allowing it to integrate easily with existing control systems.

-

Environmental Durability: The system features a rugged design with an IP65 rating, ensuring protection from dust, moisture, and harsh environmental conditions, making it ideal for industrial settings.

-

Prolongs Equipment Lifespan: By detecting and addressing potential issues early, the system helps extend the operational life of machinery, improving the overall efficiency of industrial operations.

Product Specifications:

| Specification | Details |

|---|---|

| Model Number | 3500/32 149986-02 + 125720-02 |

| Type | Vibration, Displacement, and Position Monitoring System |

| Dimensions (L x W x H) | 280 mm x 170 mm x 60 mm |

| Weight | 1.6 kg |

| Input Voltage | 24V DC |

| Measurement Range | 0 – 1000 Hz |

| Operating Temperature | -20°C to 60°C |

| Environmental Protection | NEMA 4X / IP65 |

| Mounting Type | Panel or DIN Rail |

| Communication Protocols | Modbus, Profibus, Ethernet |

Product Application:

The 3500/32 is suited for a variety of applications in industries where rotating machinery is critical to operations, including:

-

Power Generation: Used for monitoring the health of turbines, compressors, and other rotating equipment in power plants.

-

Oil & Gas: Essential for ensuring the continuous operation of pumps, compressors, and motors in oil rigs, refineries, and gas plants.

-

Chemical Processing: Helps in monitoring critical machinery like reactors, pumps, and mixers to ensure smooth operation in chemical manufacturing facilities.

-

Manufacturing: Protects motors, conveyors, and other critical machinery from unexpected failures, ensuring seamless manufacturing processes.

-

HVAC: Monitors large-scale HVAC systems used in industrial and commercial settings to ensure proper airflow and system performance.

Product Advantages:

-

Early Fault Detection: The system detects potential issues before they cause catastrophic failures, enabling predictive maintenance and reducing unplanned downtime.

-

Extended Equipment Lifespan: By detecting early signs of wear or malfunction, the 3500/32 helps prolong the life of critical machinery, saving on costly repairs or replacements.

-

Improved Operational Efficiency: With real-time monitoring and diagnostics, the system helps optimize machine performance, reducing the likelihood of unexpected breakdowns.

-

Scalability: The 3500/32 can be expanded to accommodate more machines, making it a versatile solution for both small operations and large industrial plants.

-

Durable Design: Built to withstand harsh industrial environments, the system features rugged IP65 protection, ensuring reliable operation even in dusty or moist conditions.

-

Ease of Integration: It easily integrates with existing control systems via Modbus, Profibus, and Ethernet, reducing installation complexity.

-

Cost Efficiency: By reducing downtime, extending machinery life, and minimizing the need for emergency repairs, the system contributes to significant cost savings over time.

Brand:

-

Brand: Bently Nevada

-

Brand Overview: Bently Nevada is a trusted leader in machinery condition monitoring and vibration analysis. Known for their high-quality, reliable solutions, Bently Nevada offers products that help industries monitor and protect critical machinery, minimizing downtime and maximizing operational efficiency. Their products are widely used in industries such as power generation, oil and gas, chemical processing, and manufacturing.

Series:

-

Series: Bently Nevada 3500 Series

Recommended Products in the Same Series or Related Models

| Model Number | Key Features | Weight (kg) | Dimensions (L x W x H) |

|---|---|---|---|

| 3500/40 | Vibration and displacement monitoring for turbines | 1.5 | 280 mm x 170 mm x 60 mm |

| 3500/45 | High-speed rotating equipment protection | 1.7 | 280 mm x 170 mm x 60 mm |

| 3500/53 | Machinery protection for compressors and pumps | 1.6 | 275 mm x 165 mm x 58 mm |

| 3500/22 | Vibration monitoring for motors and fans | 1.4 | 265 mm x 160 mm x 58 mm |

| 3500/77 | Protection system for turbines and motors | 1.5 | 270 mm x 165 mm x 60 mm |

Recommended Popular Models from the Same Brand

| Model Number | Key Features | Weight (kg) | Dimensions (L x W x H) |

|---|---|---|---|

| 3500/42 | Vibration and displacement sensor for rotating machinery | 1.3 | 250 mm x 160 mm x 55 mm |

| 3500/53M | Machinery protection for compressors and turbines | 1.4 | 275 mm x 160 mm x 60 mm |

| 3500/35 | Diagnostic system for gas turbines | 1.5 | 280 mm x 170 mm x 60 mm |

| 3500/22M | Monitoring and diagnostics for motors and pumps | 1.4 | 260 mm x 155 mm x 55 mm |

| 3500/90 | High-speed rotating equipment protection | 1.6 | 275 mm x 165 mm x 58 mm |

FAQ (10 Questions and Answers)

Q1: What types of machinery does the 3500/32 monitor?

A1: The 3500/32 is designed to monitor a wide range of rotating machinery, including turbines, compressors, motors, and pumps. It tracks parameters like vibration, displacement, and position to ensure the health of critical assets.

Q2: How does the 3500/32 help with predictive maintenance?

A2: The system continuously monitors the health of machinery, alerting operators to any abnormal behavior or early signs of failure. This allows for predictive maintenance, meaning issues can be addressed before they result in unplanned downtime.

Q3: What is the environmental protection rating of the 3500/32?

A3: The 3500/32 has an IP65 protection rating, meaning it is fully protected against dust and can withstand water ingress, making it suitable for challenging industrial environments.

Q4: Can the 3500/32 be used for hazardous locations?

A4: The 3500/32 is built for rugged industrial settings and can be used in areas where there are dust or moisture concerns. However, for hazardous environments with explosive gases or vapors, it’s important to verify that the product meets relevant certifications.

Q5: What is the operating temperature range for the 3500/32?

A5: The system is designed to operate in temperatures ranging from -20°C to 60°C, which makes it suitable for a wide variety of industrial settings.

Q6: Can the 3500/32 integrate with SCADA systems?

A6: Yes, the 3500/32 supports Modbus, Profibus, and Ethernet, enabling seamless integration with most SCADA and control systems.

Q7: How does the system detect faults in machinery?

A7: The 3500/32 monitors parameters such as vibration, displacement, and position. If any value exceeds preset limits, the system triggers alarms, helping operators identify potential issues before they cause damage.

Q8: How easy is it to install the 3500/32 system?

A8: The 3500/32 system is designed for easy installation, with options for both DIN rail mounting and panel mounting. Its modular design allows it to be integrated quickly into existing machinery setups, minimizing downtime during installation.

Q9: Can the 3500/32 monitor multiple machines simultaneously?

A9: Yes, the 3500/32 can be expanded to monitor multiple pieces of machinery, making it suitable for large industrial operations that require continuous monitoring of several critical machines at once.

Q10: Does the 3500/32 require a dedicated operator?

A10: While the 3500/32 provides real-time data and alerts, it is designed to be user-friendly, with intuitive interfaces and clear diagnostic information. Operators do not need to be full-time dedicated personnel, but should regularly check the system and respond to alarms when necessary.