ProductPRODUCT

Featured products

Contact Us

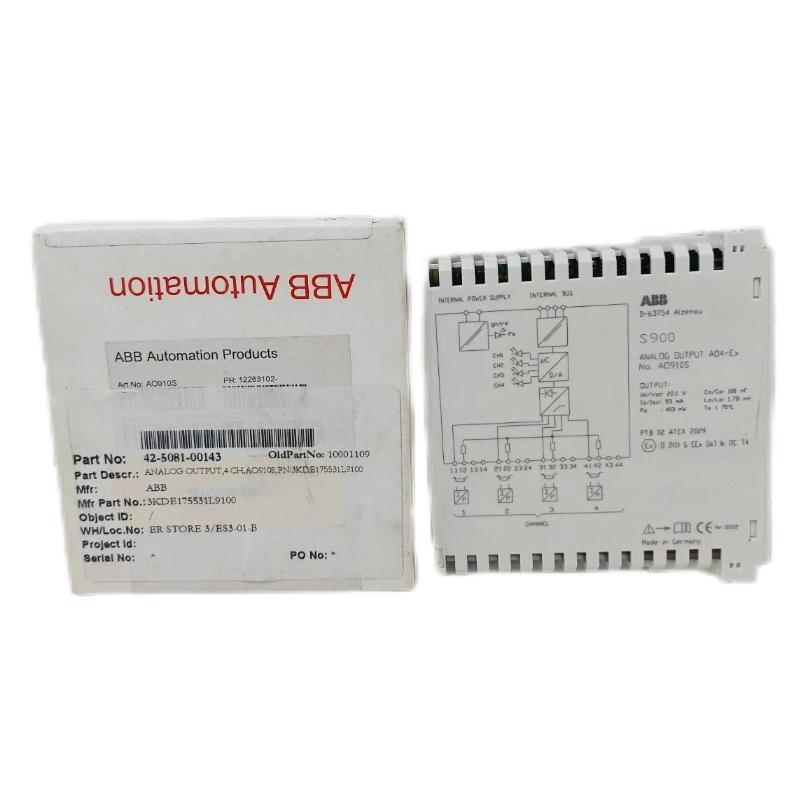

- ABB

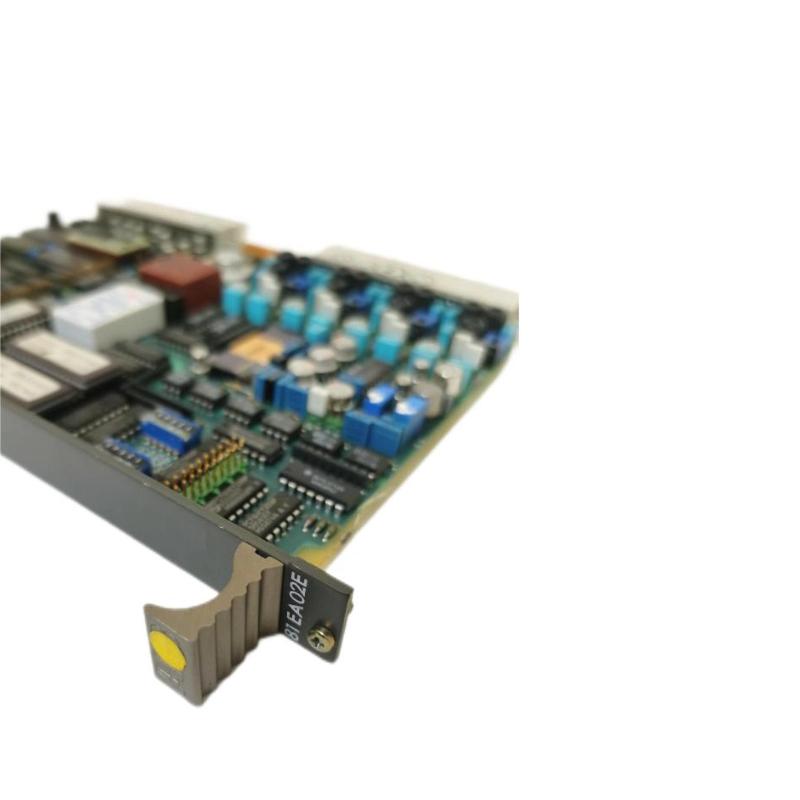

- 81EA02E

- Analog Input Module

- Sweden

- 130mm x 100mm x 60mm

- 0.7kg

- GJR2366000R1000

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 100

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

ABB 81EA02E Product Overview (Part Number: GJR2366000R1000)

Product Introduction

The ABB 81EA02E (Part Number: GJR2366000R1000) is an advanced motor protection relay designed to meet the rigorous demands of industrial applications. It belongs to ABB’s 81EA series, a range of products tailored for motor protection and control in complex industrial systems. The 81EA02E provides comprehensive protection for electric motors by monitoring key parameters such as current, voltage, and temperature. This relay ensures that motors operate within safe parameters and offers early fault detection to prevent system failures and downtime.

Designed for use in a variety of industries, the 81EA02E integrates seamlessly into motor control systems, offering users a reliable and efficient solution for motor protection. With its flexible configuration, the ABB 81EA02E relay is ideal for applications that require high performance and accuracy in motor monitoring and protection.

Product Application

The ABB 81EA02E is used in the following industrial applications:

-

Motor Protection: Primarily designed to monitor and protect electric motors from faults such as overcurrent, undercurrent, overload, and thermal damage, ensuring the longevity and reliability of motors.

-

Industrial Automation: The 81EA02E is commonly used in automated manufacturing processes, protecting the motors that drive conveyors, pumps, fans, and other machinery.

-

Energy Systems: In energy generation and distribution systems, this relay helps protect motors involved in pumping, ventilation, and cooling systems.

-

HVAC Systems: Commonly used in heating, ventilation, and air conditioning systems, the relay ensures that motors in HVAC units and large industrial air systems are protected against failures.

-

Pumping and Compressor Systems: Provides essential protection for motors in water pumps, air compressors, and other critical equipment where motor health is key to system efficiency.

Product Advantages

-

Comprehensive Protection: The ABB 81EA02E protects motors against overcurrent, undercurrent, short circuits, and thermal overload, ensuring that motors perform reliably and efficiently throughout their lifecycle.

-

Flexible Configuration: The 81EA02E can be easily configured to meet the specific needs of various industrial applications. Its ability to monitor different motor parameters makes it highly adaptable to different environments.

-

Early Fault Detection: This motor protection relay offers early fault detection capabilities, allowing operators to address potential issues before they cause significant damage or downtime.

-

Advanced Diagnostics: The ABB 81EA02E features built-in diagnostic tools that provide detailed feedback on motor performance, helping operators perform preventative maintenance.

-

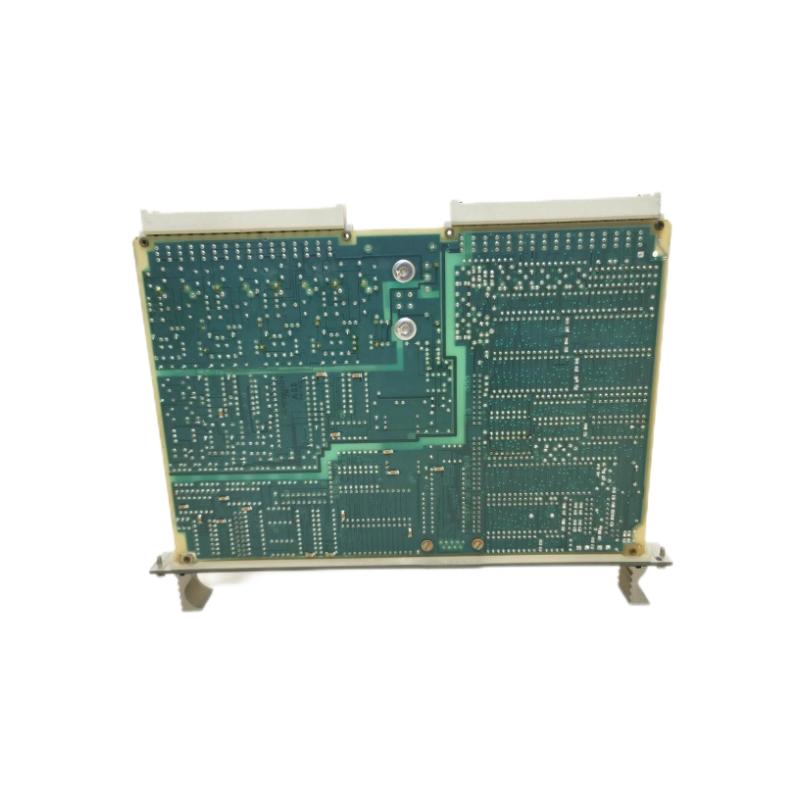

Compact Design: Its compact form factor ensures that the relay can be mounted in tight spaces, making it suitable for a wide range of installations, including control panels and industrial machinery.

-

Ease of Integration: With support for industry-standard communication protocols like Modbus RTU and RS485, the 81EA02E can be easily integrated into existing automation and control systems.

Brand and Series

-

Brand: ABB

-

Product Series: 81EA Series (Motor Protection and Control)

-

Product Line: The 81EA02E is part of ABB’s 81EA Series, designed specifically to offer reliable motor protection and monitoring for industrial motor control systems.

Product Parameters

| Specification | Details |

|---|---|

| Model | ABB 81EA02E (GJR2366000R1000) |

| Type | Motor Protection Relay |

| Nominal Current | 0.3A to 100A |

| Control Voltage | 24V DC / 110V AC |

| Operating Temperature | -20°C to 60°C |

| Dimensions (L x W x H) | 130mm x 100mm x 60mm |

| Weight | 0.7 kg |

| Material | High-grade plastic and metal |

| Mounting Type | DIN Rail Mountable |

| Environmental Protection | IP20 |

| Certifications | CE, UL, RoHS |

| Communication Interface | Modbus RTU, RS485 |

Recommended Models (Same Series/Related Models)

| Model | Description | Nominal Current | Control Voltage | Dimensions (mm) | Weight (kg) | Certifications |

|---|---|---|---|---|---|---|

| ABB 81EA01E | Basic Motor Protection Relay | 0.3A to 50A | 24V DC / 110V AC | 120 x 90 x 50 | 0.45 | CE, UL, RoHS |

| ABB 81EA03E | Advanced Motor Protection with Communication | 0.3A to 100A | 24V DC / 110V AC | 140 x 105 x 60 | 0.75 | CE, UL, RoHS |

| ABB 81EA04E | Motor Protection with Real-Time Diagnostics | 0.3A to 100A | 24V DC / 110V AC | 130 x 100 x 55 | 0.7 | CE, UL, RoHS |

| ABB 81EA05E | Motor Protection Relay with Modular Design | 0.3A to 100A | 24V DC / 110V AC | 135 x 110 x 65 | 0.8 | CE, UL, RoHS |

| ABB 81EA06E | High-Performance Motor Protection Relay | 0.3A to 100A | 24V DC / 110V AC | 145 x 110 x 70 | 0.85 | CE, UL, RoHS |

Recommended Popular ABB Models

| Model | Description | Nominal Current | Control Voltage | Dimensions (mm) | Weight (kg) | Certifications |

|---|---|---|---|---|---|---|

| ABB 5SX21 | Miniature Circuit Breaker | 6A to 25A | 230V AC | 70 x 45 x 80 | 0.2 | CE, RoHS |

| ABB 3BSE041521R1 | Motor Controller with Protection | 1A to 100A | 24V DC / 110V AC | 200 x 120 x 60 | 1.2 | CE, UL |

| ABB ACH550 | Variable Frequency Drive | 0.75 kW to 75 kW | 380V AC | 200 x 180 x 160 | 5.6 | CE, UL, RoHS |

| ABB 81MR5 | Multifunction Motor Protection Relay | 0.3A to 100A | 24V DC / 110V AC | 150 x 110 x 90 | 0.8 | CE, UL, RoHS |

| ABB DS201 | Digital Power Meter | 0.3A to 100A | 24V DC / 110V AC | 120 x 90 x 70 | 0.5 | CE, RoHS |

FAQ (10 Questions)

Q1: What is the primary purpose of the ABB 81EA02E?

A1: The ABB 81EA02E is designed to protect and monitor motors by detecting faults such as overcurrent, undercurrent, and thermal overload, ensuring that motors operate safely and efficiently.

Q2: How does the ABB 81EA02E monitor the motor?

A2: The 81EA02E continuously monitors key motor parameters such as current, voltage, and temperature. If any abnormal conditions are detected, the relay can trigger an alarm or shut down the motor to prevent damage.

Q3: What communication protocols does the ABB 81EA02E support?

A3: The 81EA02E supports Modbus RTU and RS485 communication protocols, allowing it to be easily integrated into larger control systems for centralized monitoring and control.

Q4: What is the weight of the ABB 81EA02E?

A4: The ABB 81EA02E weighs approximately 0.7 kg, making it compact and easy to install in a variety of control systems and industrial environments.

Q5: Can the ABB 81EA02E be used in harsh environments?

A5: Yes, the ABB 81EA02E is designed to operate in industrial environments with temperatures ranging from -20°C to 60°C, making it suitable for use in a wide range of applications.

Q6: What industries benefit from using the ABB 81EA02E?

A6: The ABB 81EA02E is used across various industries, including manufacturing, HVAC, energy systems, and automation, to protect motors in critical applications such as pumping, ventilation, and machinery.

Q7: How does the ABB 81EA02E contribute to energy savings?

A7: By ensuring that motors are operating within optimal parameters, the ABB 81EA02E helps prevent inefficient operation, thus saving energy and reducing operational costs over time.

Q8: Is the ABB 81EA02E easy to integrate into existing systems?

A8: Yes, the 81EA02E is designed for easy integration into industrial control systems, thanks to its support for widely used communication protocols like Modbus RTU.

Q9: What mounting options are available for the ABB 81EA02E?

A9: The ABB 81EA02E can be easily mounted on a DIN rail, making installation simple and flexible for a wide range of industrial control panel setups.

Q10: Does the ABB 81EA02E have diagnostic capabilities?

A10: Yes, the ABB 81EA02E includes built-in diagnostics that provide detailed information on motor performance, allowing operators to identify and address issues before they lead to failure.