ProductPRODUCT

Featured products

Contact Us

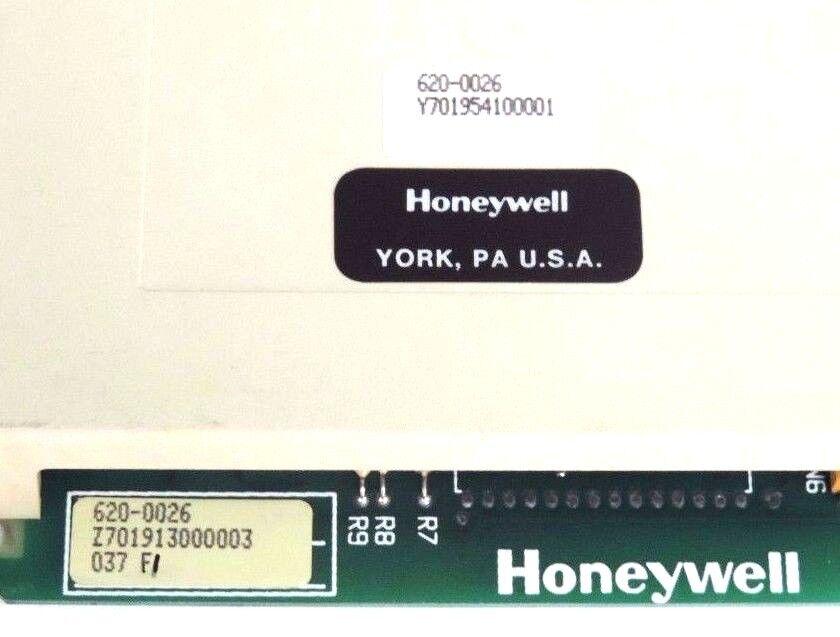

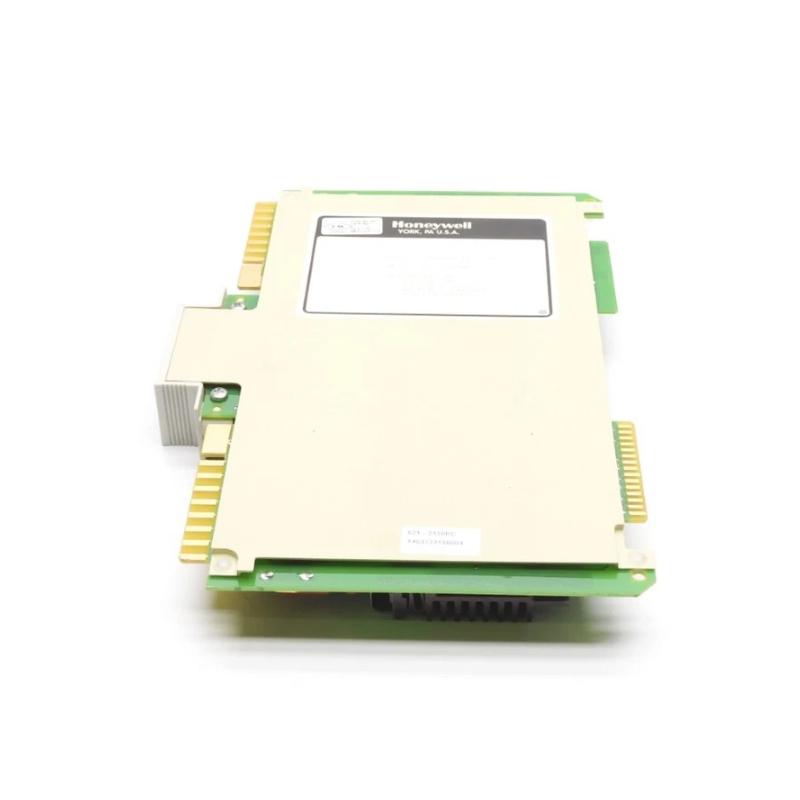

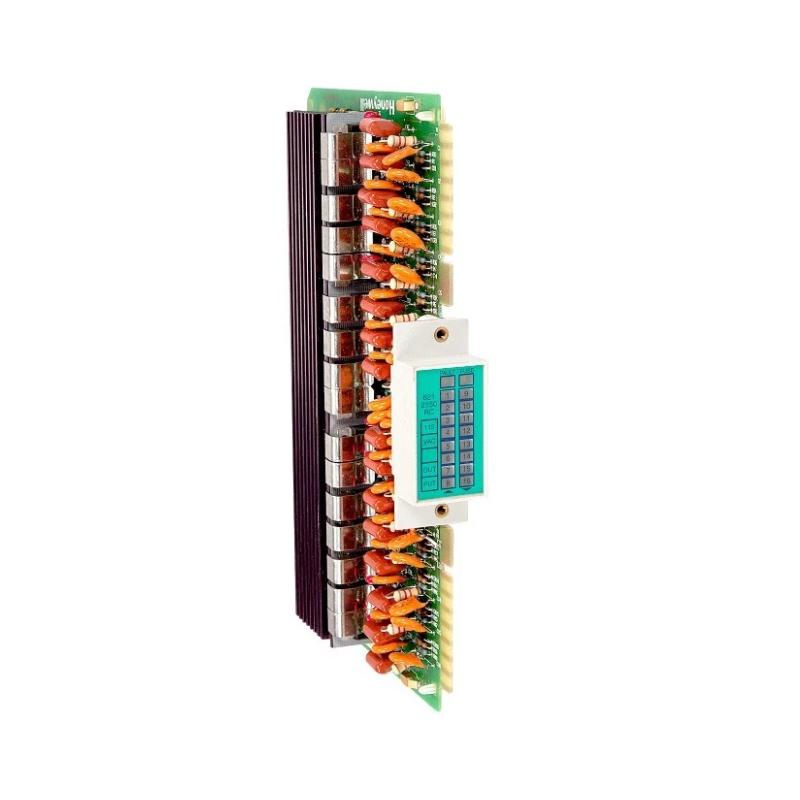

- Honeywell

- 621-2150RC

- 16-Point I/O Module

- USA

- 100 × 55 × 45 mm

- 0.35kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 0

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Honeywell 621-2150RC Pressure Sensor — Comprehensive Product Description, Specifications, Applications, Advantages, Recommended Models, Brand Popular Models, and FAQ

1. Product Name and Overview

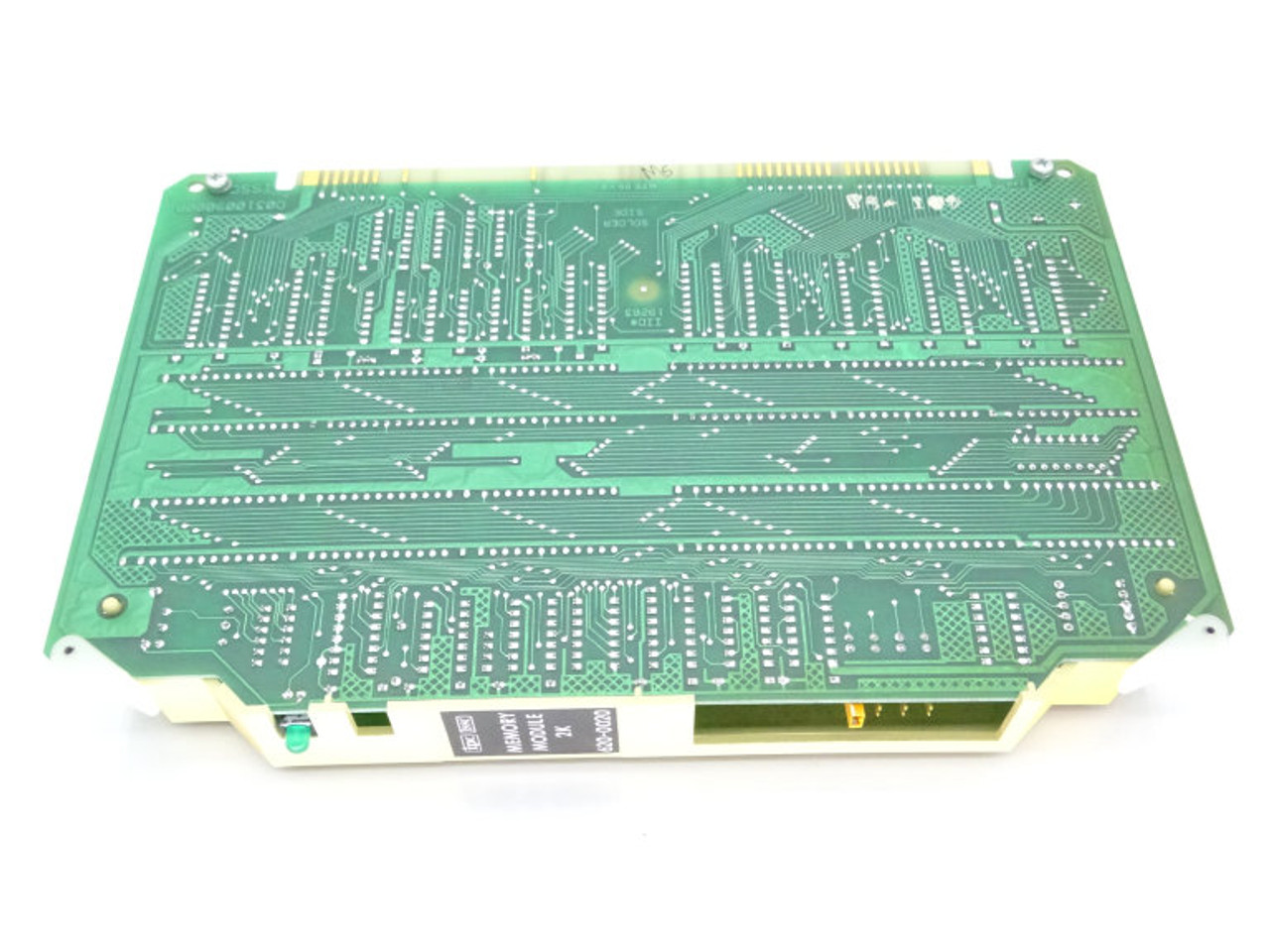

Product Name: Honeywell 621-2150RC / 6212150RC

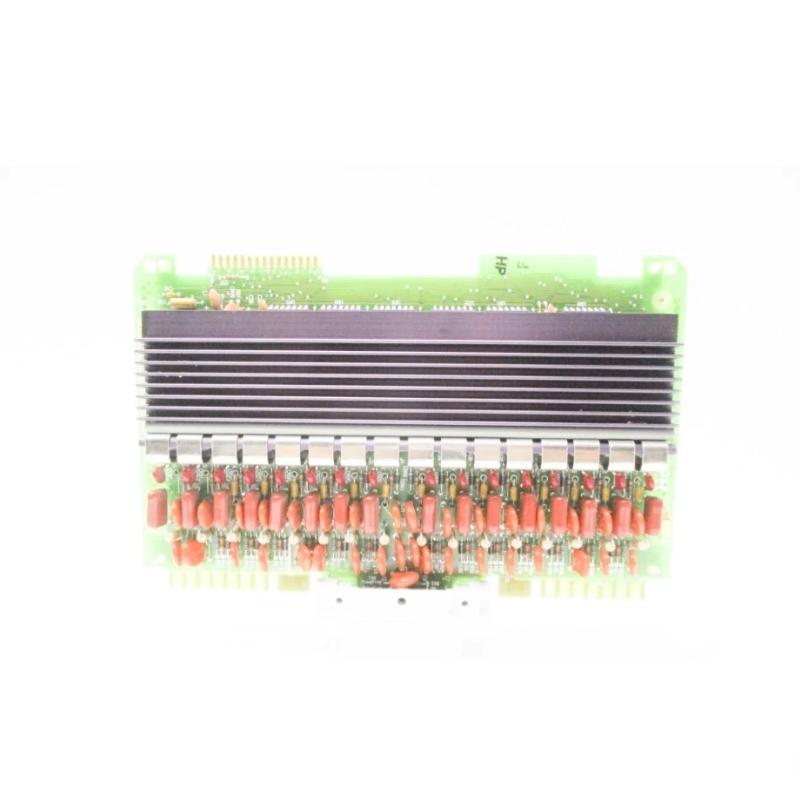

The Honeywell 621-2150RC is a robust industrial pressure sensor designed to measure gauge pressure in demanding environments. This sensor combines high accuracy, long-term stability, and rugged construction to meet the needs of industrial control, automation and system monitoring. The “RC” designation denotes a reinforced corrosion-resistant version, engineered for harsher conditions such as exposure to water spray, humidity, vibration and challenging environmental contaminants.

The 621-2150RC delivers dependable analog output signals that integrate seamlessly with controllers, data acquisition systems and programmable logic controllers (PLC). It is suitable for process measurement, feedback control, safety interlocks and system health diagnostics in fluid power and pressure-dependent systems.

2. Brand and Series

Brand: Honeywell

Series: 621 Series Industrial Pressure Sensors

The 621 Series is a family of industrial pressure sensors known for reliability, compact design, selectable output options and durable housings. These sensors are used widely across industrial automation, HVAC systems, hydraulic and pneumatic machinery, water and wastewater systems, and mobile equipment.

3. Product Specifications

| Parameter | Specification |

|---|---|

| Model | 621-2150RC |

| Pressure Type | Gauge pressure |

| Pressure Range | 0–1500 PSI |

| Accuracy | ±0.5% of Full Scale (FS) |

| Output Signal | Selectable: 4–20 mA or 0–10 VDC |

| Supply Voltage | 10–30 VDC |

| Response Time | ≤ 5 ms |

| Temperature Range | –40°C to +125°C |

| Media Compatibility | Air, inert gases, non-corrosive hydraulic fluids |

| Mechanical Connection | 1/4″ NPT Male |

| Electrical Connector | Industrial sealed 3-pin connector |

| Dimensions (L × W × H) | 100 × 55 × 45 mm |

| Weight | 0.35 kg |

| Housing Material | Stainless steel with corrosion-resistant finish |

| Seal Material | Viton or Buna-N elastomer |

| Environmental Protection | IP68 |

| Vibration Resistance | 10 g |

| Shock Resistance | 50 g |

4. Product Applications

The Honeywell 621-2150RC pressure sensor is ideal for a wide range of industrial and commercial applications where precise pressure measurement and long-lasting performance are required.

Industrial Automation:

Installed in automated production lines to monitor pneumatic and hydraulic pressures that control actuators, valves and safety interlocks. Accurate pressure data helps maintain consistent production rates and reduce system stress.

Hydraulic & Pneumatic Machinery:

Used in hydraulic circuits, pumps, valves, actuators and mobile equipment where high pressure needs monitoring. It supports preventive maintenance by alerting operators to abnormal pressure changes.

HVAC and Refrigeration:

This sensor measures pressure in refrigerant lines, blower ducts and compressor circuits. It helps regulate cooling cycles, improve system efficiency and protect against overpressure events.

Water & Wastewater Systems:

Deployed in pump control systems, filtration lines and distribution networks to ensure correct pressure is maintained. It supports energy-efficient operation and prevents damage caused by pressure surges.

Process Control in Manufacturing:

Used in food processing, chemical plants and pharmaceutical lines where accurate pressure feedback ensures quality control, safety interlocks and regulatory compliance.

Energy & Power Systems:

Monitors oil pressure in generators, steam line pressures, and fluid systems in power plants. Consistent pressure feedback enhances safety and reliability in energy generation equipment.

5. Product Advantages

The 621-2150RC offers several key benefits that make it suitable for demanding pressure sensing tasks:

High Precision and Stability:

With ±0.5% full-scale accuracy, it delivers consistent and repeatable pressure readings, which are essential for process control and monitoring.

Reinforced Corrosion Resistance:

The corrosion-resistant sensor housing extends service life in wet, humid or chemically challenging environments.

Selectable Output Signals:

Selectable 4–20 mA or 0–10 VDC outputs make the sensor compatible with a wide range of PLCs, controllers and data acquisition systems without needing signal converters.

Wide Operating Temperature Range:

Capable of operating from –40°C to +125°C, it remains stable in both cold outdoor environments and hot industrial enclosures.

Industrial Protection:

IP68 environmental protection rating ensures dust resistance and temporary immersion protection, lowering the risk of field failures.

Compact and Space-Efficient:

Despite its rugged construction, the sensor is compact and mountable in tight spaces using standard 1/4″ NPT fittings.

High Shock and Vibration Resistance:

Designed to withstand mechanical shocks up to 50 g and vibrations up to 10 g, making it suitable for mobile equipment and heavy machinery.

6. Related Models in the Same Series or Similar Types

Below are five related or comparable models from the 621 Series that offer similar functionality but differ in pressure range or specific features:

| Model | Pressure Range | Output | Accuracy | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|---|

| 621-1201RC | 0–200 PSI | 4–20 mA | ±0.5% FS | 80 × 45 × 35 | 0.24 |

| 621-1500RC | 0–500 PSI | 0–10 VDC | ±0.5% FS | 90 × 50 × 40 | 0.29 |

| 621-2100RC | 0–1000 PSI | 4–20 mA | ±0.5% FS | 95 × 52 × 42 | 0.33 |

| 621-2500RC | 0–2000 PSI | 4–20 mA | ±0.5% FS | 105 × 58 × 48 | 0.41 |

| 621-3000RC | 0–3000 PSI | 4–20 mA | ±0.5% FS | 110 × 60 × 50 | 0.47 |

7. Popular Models from the Same Brand

Below are five widely used sensor models from the same brand. These are known for excellent performance across various industrial measurement tasks:

| Model | Sensor Type | Key Feature | Output | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|---|

| PX90 | Pressure Transducer | High accuracy for industrial use | 4–20 mA / 0–10 V | 92 × 50 × 45 | 0.33 |

| SCX Series | Differential Pressure Sensor | Accurate ΔP measurements | 4–20 mA | 80 × 40 × 30 | 0.21 |

| ABP Series | Board-Mount Pressure Sensor | Compact design for OEM integration | Analog / Digital | 30 × 20 × 12 | 0.05 |

| TCR700 | Temperature Sensor | Wide temperature range | 4–20 mA | 65 × 22 × 15 | 0.14 |

| RH700 | Humidity & Temperature Sensor | Dual parameter sensing | Digital | 48 × 48 × 16 | 0.11 |

8. Frequently Asked Questions (FAQ)

Q1: What type of pressure does the 621-2150RC measure?

A1: The sensor measures gauge pressure, which is pressure measured relative to atmospheric pressure rather than absolute pressure.

Q2: What is the maximum pressure range of this model?

A2: The 621-2150RC is designed to reliably measure pressures from 0 to 1500 PSI.

Q3: What makes the “RC” version different from standard models?

A3: The “RC” indicates reinforced corrosion resistance, with enhanced housing materials and sealing to perform better in wet, humid or contaminant-rich environments.

Q4: What output signals are available on this sensor?

A4: Users can select between 4–20 mA current loop or 0–10 VDC voltage output, depending on system requirements.

Q5: Can the sensor be used in outdoor environments?

A5: Yes. With a wide operating temperature range (–40°C to +125°C) and IP68 protection, it is suitable for outdoor and industrial environments.

Q6: What fluids or gases can this sensor measure?

A6: The sensor is compatible with air, inert gases and most non-corrosive hydraulic fluids. Always confirm compatibility with specific media before use.

Q7: What mechanical connection does the sensor use?

A7: It uses a 1/4″ NPT male threaded mechanical connection, which is a standard industrial interface.

Q8: How should the sensor be installed to ensure accurate readings?

A8: The sensor should be securely threaded into a fitting with appropriate sealing compound, mounted on a surface with minimal vibration, and protected from direct impact or shock.

Q9: Is periodic calibration necessary?

A9: Although the sensor is factory calibrated, periodic verification or calibration may be recommended for critical or safety-related applications.

Q10: Which industries commonly use this model?

A10: Industries such as manufacturing automation, hydraulics, HVAC/R systems, water/wastewater treatment, power generation, and mobile machinery commonly use this pressure sensor for reliable pressure monitoring.