ProductPRODUCT

Featured products

Contact Us

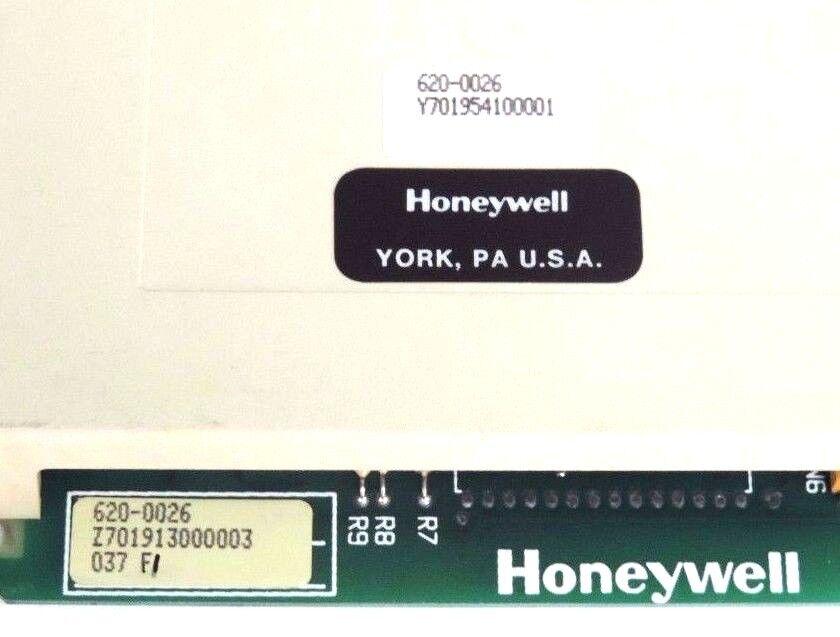

- Honeywell

- 621-2100R

- Industrial Output Module

- USA

- 95 × 50 × 40 mm

- 0.32kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 0

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Honeywell 621-2100R Pressure Sensor — Full Product Description, Specifications, Applications, Advantages, Related Models, Popular Brand Models, and FAQ

1. Product Name and Introduction

Product Name: Honeywell 621-2100R

The Honeywell 621-2100R is an industrial-grade pressure sensor designed to provide accurate, repeatable pressure measurements in demanding environments. It is a ruggedized version of the standard 621-2100 sensor, featuring reinforced materials and environmental protections to withstand harsh industrial conditions, including vibration, moisture, temperature extremes, and mechanical stress.

The sensor delivers a reliable analog output compatible with a wide range of controllers, programmable logic controllers (PLC), data acquisition systems, and industrial monitoring equipment. It is suitable for applications where long-term stability, robust housing, and dependable performance are essential.

This description provides detailed specifications, practical applications, key advantages, related product recommendations, popular models from the same brand, and a carefully written set of frequently asked questions.

2. Brand and Series

Brand: Honeywell

Series: 621 Series Industrial Pressure Sensors

The 621 Series is a family of compact industrial pressure sensors known for their rugged construction, selectable output options, wide temperature tolerance, and dependable operation in pneumatic, hydraulic, and fluid pressure measurement tasks. These sensors are widely used in automation, process control, fluid power systems, and equipment monitoring.

3. Detailed Specifications

| Parameter | Specification |

|---|---|

| Model | 621-2100R |

| Pressure Type | Gauge pressure, relative to ambient |

| Pressure Range | 0–1000 PSI |

| Accuracy | ±0.5% of Full Scale (FS) |

| Output Signal | Selectable: 4–20 mA or 0–10 VDC |

| Supply Voltage | 10–30 VDC |

| Response Time | ≤ 5 ms |

| Temperature Range | –40°C to +125°C |

| Media Compatibility | Air, inert gases, non-corrosive oils |

| Mechanical Connection | 1/4″ NPT Male |

| Electrical Connector | Industrial 3-pin sealed connector |

| Dimensions (L × W × H) | 95 × 50 × 40 mm |

| Weight | 0.32 kg |

| Enclosure Protection | IP68 |

| Vibration Resistance | 10 g |

| Shock Resistance | 50 g |

| Housing Material | Stainless steel with reinforced protective finish |

| Seal Material | Viton or Buna-N elastomer |

4. Product Applications

The Honeywell 621-2100R pressure sensor is engineered for a broad range of industrial and commercial applications where accurate pressure monitoring is required for safety, control, and performance.

Industrial Automation Systems

In automated production lines, this sensor provides feedback to controllers for pneumatic and hydraulic systems. Reliable pressure information helps maintain consistent motion, protects cylinders and actuators, and supports safety interlocks when system pressure deviates from expected values.

Hydraulic Equipment and Mobile Machinery

Used on construction machinery, agricultural equipment, and other mobile systems to monitor hydraulic circuit pressure, ensuring safe operation under heavy load and preventing damage caused by high pressure or fluid starvation.

Process Control and Manufacturing

In chemical, food, pharmaceutical, and packaging facilities, the sensor measures pressure in tanks, reactors, and pipelines. Accurate data supports closed-loop control systems, ensuring product quality and process consistency.

HVAC and Refrigeration Systems

Installed in heating, cooling, and refrigeration systems to measure refrigerant pressure, duct pressure, and line pressures. These measurements assist in optimizing system performance and protecting compressors from operating outside recommended pressure ranges.

Water and Wastewater Treatment Plants

Monitors pressure in pump stations, distribution lines, and filtration systems. Consistent feedback helps prevent overpressure events, supports energy efficiency, and ensures reliable operation of treatment and distribution systems.

Power Generation and Equipment Monitoring

Used in power plants and auxiliary systems to monitor lubricating oil pressure, steam system pressures, and hydraulic pressures associated with turbines, valves, and support machinery.

5. Product Advantages

The 621-2100R model offers a number of significant advantages that make it well suited for challenging industrial environments.

High Accuracy and Stability

With ±0.5% full-scale accuracy, this sensor provides pressure readings with minimal error. This high degree of precision supports effective system regulation and reliable feedback.

Ruggedization and Reinforced Protection

Enhanced mechanical design and protective housing extend the sensor’s service life in environments exposed to vibration, physical shock, moisture, and temperature extremes.

Selectable Output Options

The ability to choose between a 4–20 mA current loop or 0–10 VDC voltage output allows seamless interface with a variety of industrial controllers and data systems without additional converters.

Wide Operating Temperature Range

Operation from –40°C to +125°C makes the sensor suitable for outdoor installations and industrial enclosures without loss of performance across temperature extremes.

Industrial-Grade Environmental Resistance

An IP68 protection rating against dust ingress and prolonged immersion in water ensures dependable performance in wet and dusty conditions often encountered in manufacturing floors and outdoor installations.

Compact and Efficient Footprint

The compact dimensions and standard 1/4″ NPT mechanical connection enable easy mounting into existing systems without large space requirements or special adapters.

6. Related Models in the Same Series

Below are five related or comparable models within the 621 Series or closely related industrial pressure sensors. These models share similar design philosophies but vary in pressure range, output options, or specific application focus.

| Model | Pressure Range | Output | Accuracy | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|---|

| 621-1100R | 0–50 PSI | 0–5 VDC | ±0.75% FS | 70 × 40 × 30 | 0.18 |

| 621-1180R | 0–100 PSI | 4–20 mA | ±0.5% FS | 75 × 42 × 35 | 0.22 |

| 621-1201R | 0–200 PSI | 4–20 mA | ±0.5% FS | 80 × 45 × 35 | 0.24 |

| 621-1500R | 0–500 PSI | 0–10 VDC | ±0.5% FS | 90 × 50 × 40 | 0.30 |

| 621-2500R | 0–1500 PSI | 4–20 mA | ±0.5% FS | 100 × 55 × 45 | 0.38 |

7. Popular Models from the Same Brand

Below are five popular sensor models from the same brand, chosen for their broad usage and performance across industrial measurement applications.

| Model | Type | Key Feature | Output | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|---|

| PX90 Pressure Transducer | Industrial Pressure Transducer | High accuracy industrial grade | 4–20 mA / 0–10 V | 90 × 50 × 45 | 0.32 |

| SCX Differential Sensor | Differential Pressure Sensor | Measures small differential ΔP | 4–20 mA | 80 × 40 × 30 | 0.22 |

| FTL300 Flow Sensor | Flow Measurement Sensor | Airflow rate monitoring | Pulse / Analog | 95 × 60 × 35 | 0.28 |

| TCR600 Temperature Probe | Temperature Sensor | Wide temperature detection range | 4–20 mA | 60 × 20 × 15 | 0.12 |

| RH600 Humidity Sensor | Humidity & Temperature Sensor | Dual humidity and temperature | Digital | 45 × 45 × 15 | 0.10 |

8. Frequently Asked Questions (FAQ)

Q1: What exactly does the Honeywell 621-2100R measure?

A1: It measures gauge pressure, which is pressure relative to ambient atmospheric conditions. This allows monitoring and control of pressures in systems where relative rather than absolute measurement is required.

Q2: What output options are available with this sensor?

A2: The 621-2100R offers selectable analog outputs: a 4–20 mA current loop or a 0–10 VDC voltage signal. These outputs are commonly supported by industrial controllers and acquisition systems.

Q3: What is the pressure range of this model?

A3: The standard configuration for the 621-2100R covers a pressure range from 0 PSI up to 1000 PSI, making it suitable for many industrial pressure monitoring tasks.

Q4: How accurate is the 621-2100R?

A4: This model has a typical accuracy of ±0.5% of full scale, meaning the sensor output will be within this tolerance of the actual pressure value over its specified range.

Q5: Is this sensor suitable for outdoor installations?

A5: Yes. With an operating temperature range from –40°C to +125°C and IP68 environmental protection, it can be used outdoors and in industrial environments with temperature extremes.

Q6: What media can this sensor measure?

A6: It is designed to measure air, inert gases, and many non-corrosive hydraulic fluids or oils. It is important to check the compatibility of the specific fluid used in each application.

Q7: What type of mechanical connection does the sensor use?

A7: The 621-2100R uses a standard 1/4″ NPT male threaded mechanical connection for easy installation into pipelines, manifolds, or instrument ports.

Q8: How should the sensor be mounted to maintain accuracy?

A8: Install the sensor in a location with minimal vibration, secure the threaded connection with appropriate sealant, and ensure electrical connectors are protected from environmental exposure.

Q9: Does this sensor require periodic calibration?

A9: The sensor is factory-calibrated, but periodic verification or calibration may be recommended depending on the criticality of the application and operational requirements.

Q10: What industries are common users of this sensor model?

A10: Industries that commonly use this sensor include manufacturing automation, process control, water and wastewater treatment, HVAC systems, mobile machinery, and energy systems where reliable pressure feedback is necessary.