ProductPRODUCT

Featured products

Contact Us

- Bently Nevada

- 330850-91-CN

- Proximitor Sensor

- USA

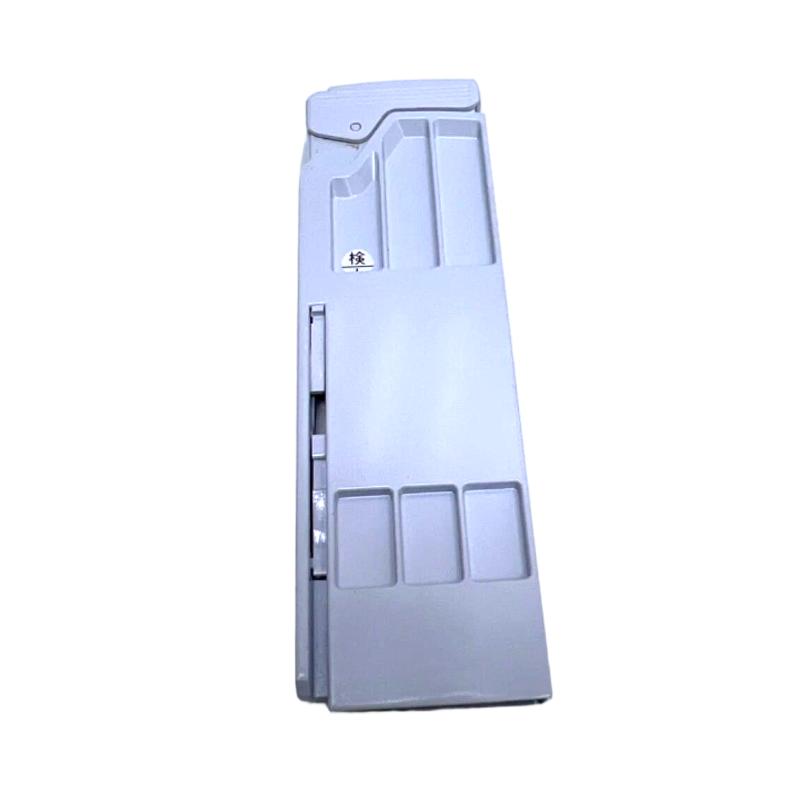

- 78 mm × 60 mm × 65 mm

- 0.22kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 184

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

1. Product Overview — Bently Nevada 330850‑91‑CN

Introduction

The Bently Nevada 330850‑91‑CN is a non‑contact Proximitor / proximity transducer module in the 3300 XL 25 mm sensor family. Its function is to convert minute changes in the gap between a rotating shaft and a fixed reference (via a 25 mm proximity probe and extension cable) into an electrical voltage signal. The “91” designation indicates a 9.1 metre system length and DIN / rack‑oriented mounting compatibility. The suffix “CN” designates a China / regional compliance variant, typically meaning it is labeled, certified, or packaged for the Chinese market, while retaining the same measurement performance as its global-certified peers.

Because of its extended reach and regional variant status, this model is ideal when the sensor electronics must be located remotely from the probe (for layout, environmental, or access reasons) but regional compliance (CN) is required or preferred.

It is a product of the Bently Nevada brand, belonging to the 3300 / 3300 XL proximity sensor ecosystem.

2. Technical Specifications

Below is a table of expected or typical parameters for 330850‑91‑CN. Because “CN” mainly affects compliance/labeling, the core mechanical/electrical specs align with certified models. Dimensions and weight are included.

| Parameter | Specification / Typical Value |

|---|---|

| Model | 330850‑91‑CN |

| Series / Type | 3300 XL 25 mm Proximitor (non‑contact displacement / vibration) |

| Total System Length | 9.1 metres (probe + extension cable + module) |

| Mounting / Mount Style | DIN / rack‑friendly (“91” type) |

| Regional Variant | China / CN variant (regional compliance, labeling) |

| Measurement / Linear Range | ~0.25 mm to ~25 mm (approximate linear zone) |

| Sensitivity | ~0.787 V/mm (nominal standard) |

| Output Voltage Range | –2 V to –18 V (typical proportional output) |

| Supply Voltage | –17.5 VDC to –26 VDC |

| Current Consumption | < 3.5 mA (typical) |

| Operating Temperature | –40 °C to +85 °C |

| Storage Temperature | –50 °C to +100 °C |

| Humidity / Environmental Tolerance | 0 to 95 % RH, non-condensing |

| Dimensions (L × W × H) | ~78 mm × 60 mm × 65 mm |

| Weight (module only, kg) | ~0.22 kg |

| Shipping / Packaged Weight | ~1.8 to 2.0 kg (with packaging and accessories) |

| Terminal / Connector Type | SpringLoc® or equivalent tool‑free terminal strips |

| EMI / RFI Immunity | Industrial shielding and filtering to resist electromagnetic interference |

| Approval / Certification | Regional CN variant compliance (for Chinese market) |

| Material / Enclosure | Aluminum alloy module housing |

Note: The “CN” suffix typically does not change mechanical housing or measurement performance; it primarily addresses regional labeling, certifications, or compliance.

3. Applications

The 330850‑91‑CN is suited for demanding industrial environments where extended wiring distance and regional compliance are necessary. Typical applications include:

-

Steam and gas turbine rotor displacement / vibration monitoring

-

Large generators and motors

-

Compressors, pumps, fans in petrochemical, power, process plants

-

Long cable runs from probe to instrumentation room

-

Retrofitting older proximity systems to modern 3300 XL standards

-

Condition monitoring, vibration diagnostics, predictive maintenance systems

-

Machinery in chemical, refining, oil & gas, power generation sectors

-

Control cabinet layouts where sensors must be physically removed from vibration/noise zones

Its 9.1 m reach gives flexibility in routing and placement of electronics relative to the probe.

4. Advantages & Key Features

The 330850‑91‑CN delivers several advantages and design strengths:

-

Long-distance capability (9.1 m reach)

Permits placing the electronic module remotely from the probe location without repeaters or signal boosters. -

Regional compliance (CN variant)

Meets Chinese market regulatory and labeling requirements, simplifying deployment in that region. -

DIN / rack-style mounting (91 form)

Designed to integrate into DIN-rail or rack systems, enabling modular installation in control cabinets. -

High measurement fidelity

Stable sensitivity, wide linear zone, and minimal drift enable accurate displacement monitoring over time. -

Robust EMI / RFI resistance

Built-in shielding and filtering help maintain signal integrity in electrically noisy industrial environments. -

Compact, lightweight design

The module’s modest size (~78×60×65 mm) and weight (~0.22 kg) ease installation in tight spaces. -

Compatibility with 3300 XL ecosystem

Compatible with 25 mm probes, extension cables, and monitoring modules, simplifying integration and upgrades. -

Reliability and durability

Engineered for continuous industrial operation with low drift and long service life under proper conditions. -

Tool-free wiring

SpringLoc or equivalent terminals facilitate rapid wiring and secure connections in the field.

5. Related / Same-Series Model Recommendations (5 Models)

Here are five models in or adjacent to the 330850 / 3300 XL 25 mm proximity sensor series. The model column is bolded.

| Model | System Length / Mounting | Approval / Variant | Approx. Weight / Size | Key Differences / Notes |

|---|---|---|---|---|

| 330850‑91‑05 | 9.1 m, DIN mount | Certified (“05”) | ~0.22 kg | Certified version of this 9.1 m DIN model |

| 330850‑90‑05 | 9.0 m, panel mount | Certified (“05”) | ~0.22 kg | Panel-mounted certified 9 m version |

| 330850‑91‑00 | 9.1 m, DIN mount | Non‑approval (“00”) | ~0.22 kg | DIN version without certifications |

| 330850‑50‑05 | 5.0 m, panel mount | Certified (“05”) | ~0.10 kg | Shorter reach, panel certified variant |

| 330850‑51‑05 | 5.0 m, DIN mount | Certified (“05”) | ~0.10 kg | DIN-mounted certified 5 m version |

These variants cover different lengths (5 vs 9.1 m), mounting styles (panel vs DIN), and approval status, providing flexibility depending on layout and certification needs.

6. Popular Models from the Same Brand (5 Examples)

Here are five well-known or commonly used modules / sensors in the Bently Nevada product ecosystem:

| Model | Function / Type | Key Attributes / Role | Typical Use Case |

|---|---|---|---|

| 330105‑02‑12‑05‑02‑00 | Proximity probe / sensor module | Customizable tip / stem | Shaft displacement sensing in 3300 systems |

| 3500 / 05‑01‑01‑00‑00 | Monitoring / rack module | Multi-channel, slot architecture | Central vibration and condition monitoring |

| 9200‑03‑05‑10‑00 | Smart sensor / advanced condition module | High resolution, digital output | Remote diagnostic, IIoT integration |

| 176449‑03 | Signal conditioning / interface module | Filtering, signal translation | Integration support in monitoring systems |

| 330500 Velomitor | Velocity vibration transducer | Outputs velocity rather than displacement | Complementary vibration monitoring |

7. FAQs (10 Q / A)

Q1: What distinguishes 330850‑91‑CN from 330850‑91‑05?

A1: The “CN” suffix indicates a regional variant tailored for Chinese market compliance, while “05” indicates full international approvals. Their measurement behavior is largely the same.

Q2: Why select the 9.1 m reach (91) version?

A2: To accommodate installations where the module must be placed some distance from the probe, such as in separate control rooms, remote panels, or to avoid vibration/noise zones.

Q3: What does the “CN” suffix imply?

A3: It implies local/regional labeling, compliance, or packaging suited for the Chinese market or required local approvals.

Q4: Is 330850‑91‑CN compatible with other 3300 XL components?

A4: Yes. It uses the same probe interface, extension cable standards, and output behavior as other 3300 XL 25 mm components, enabling seamless integration.

Q5: What is the measurement linear range?

A5: The linear displacement window is approximately 0.25 mm to 25 mm; beyond that, output may turn non‑linear or saturate.

Q6: What are the physical size and weight?

A6: The proximitor module measures ~78 × 60 × 65 mm, weighs ~0.22 kg; packaged, shipping weight is about 1.8 to 2.0 kg.

Q7: How strong is its EMI / RFI protection?

A7: It has industrial-grade shielding and filtering to preserve signal integrity under high electromagnetic noise, though not specialized for extremely harsh emission zones.

Q8: Can it be calibrated in the field?

A8: Yes — zero/span can be adjusted in the field, provided appropriate calibration tools and reference standards are used. Factory calibration ensures optimal performance.

Q9: What is the estimated service life?

A9: With proper installation, environment control, and maintenance, it typically operates reliably for many years, often 5–10+ years.

Q10: Can it measure non-ferrous targets accurately?

A10: The sensor is optimized for ferrous metal (steel, iron) surfaces. Using non-ferrous materials may reduce sensitivity or accuracy and is not recommended for critical monitoring.