ProductPRODUCT

Featured products

Contact Us

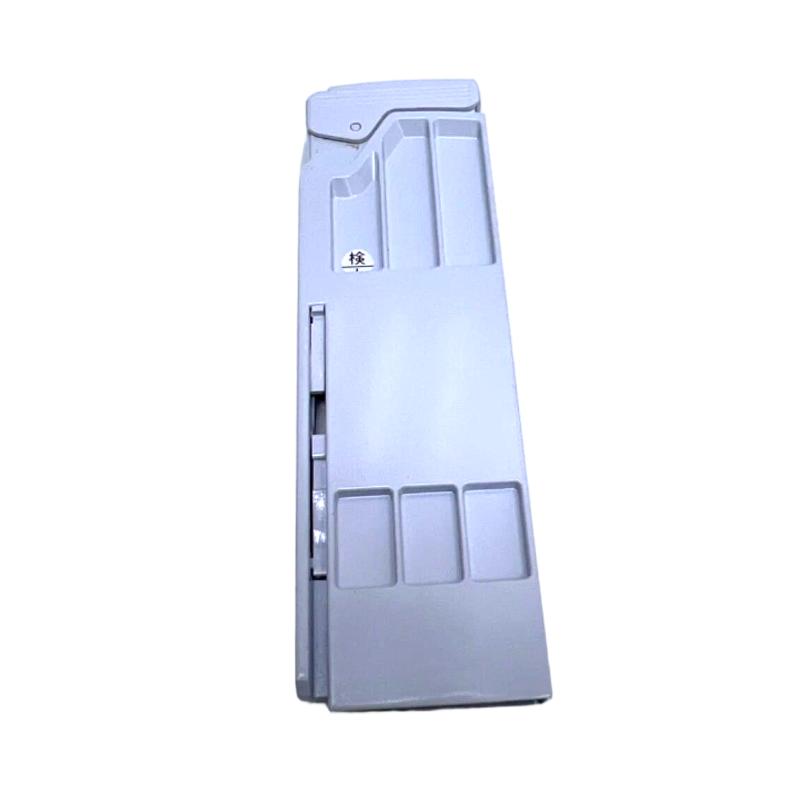

- Bently Nevada

- 330850-51-05

- Proximitor Sensor

- USA

- 105 mm (L) × 75 mm (W) × 25 mm (H)

- 0.255kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 135

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

📌 Product Overview – Bently Nevada 330850-51-05

The Bently Nevada 330850-51-05 is a non-contact proximity sensor system that is part of the 3300 XL 25 mm Proximitor Sensor Series. It is engineered for precise, reliable measurement of shaft displacement, radial vibration, and position in rotating machinery.

This model is primarily used with turbine generators, compressors, pumps, fans, and other high-value assets in industrial environments requiring continuous condition monitoring. The 330850-51-05 version features a 5.0-meter system length and DIN-rail mounting, with global compliance certifications under the “-05” suffix.

📊 Technical Specifications – Bently Nevada 330850-51-05

| Parameter | Specification |

|---|---|

| Model | 330850-51-05 |

| Series | 3300 XL 25 mm Proximitor Sensor |

| System Length | 5.0 meters (probe + extension cable + proximitor) |

| Mounting Type | DIN rail installation |

| Approvals | Multiple certifications (-05 suffix) such as CE, ATEX, IEC |

| Power Supply | -17.5 to -26 VDC (no isolator); -23 to -26 VDC (with isolator) |

| Power Sensitivity | < 2 mV/V power variation impact |

| Temperature (Operating) | -35°C to +85°C |

| Temperature (Storage) | -51°C to +100°C |

| Measurement Range | Approx. 0.25 mm to 12.5 mm (linear range, depending on probe) |

| Output | Voltage proportional to target proximity |

| Frequency Response | Suitable for high-speed rotating machinery (typically up to 10 kHz) |

| EMI/RFI Immunity | High protection against electrical noise |

| Enclosure Material | Industrial-grade aluminum alloy |

| Connection Terminals | SpringLoc™ terminals (tool-free wiring) |

| Dimensions | Approx. 105 mm (L) × 75 mm (W) × 25 mm (H) (estimated) |

| Weight | Approx. 0.255 kg |

| Shipping Weight | Approx. 1.3 kg (including packaging and accessories) |

🧠 Product Features & Advantages

-

Non-contact Sensing: Eliminates wear and friction while ensuring precise shaft displacement and vibration monitoring.

-

High Accuracy: Delivers accurate, linear output with minimal drift or deviation, ideal for predictive maintenance.

-

Strong Environmental Tolerance: Functions in extreme temperatures, high-vibration areas, and electrically noisy environments.

-

DIN Rail Mounting: Allows for compact, space-saving installations within control panels.

-

Global Compliance: Certified for hazardous area usage with multiple global standards.

-

High Interchangeability: Compatible with other Bently Nevada 3300 XL probes, extension cables, and monitoring systems.

-

Long-term Reliability: Designed to operate for years in industrial applications with minimal maintenance.

-

Proven Brand Trust: Backed by decades of reliability in power plants, petrochemical sites, and offshore platforms.

🏭 Application Areas

-

Steam & gas turbine shaft vibration/displacement monitoring

-

Compressors, gearboxes, and fan rotor dynamic analysis

-

Large electric motors and generators in critical process environments

-

Oil & gas and petrochemical plants

-

Hydropower and wind turbine monitoring systems

-

Condition-based maintenance (CBM) and predictive monitoring systems

🏷️ Brand and Series

| Attribute | Detail |

|---|---|

| Brand | Bently Nevada |

| Series Name | 3300 XL |

| Sensor Sub-series | 25 mm Proximitor Sensors |

| Installation Type | DIN Rail |

| Mounting Option | “51” indicates DIN mounting |

| Certification Type | “05” indicates multi-approval |

🔁 5 Related Models from the Same Series

| Model | System Length | Mounting Type | Certification | Weight | Notes |

|---|---|---|---|---|---|

| 330850-50-05 | 5.0 m | Panel Mount | Multi-Approved | ~0.1 kg | Same length, different mounting |

| 330850-51-00 | 5.0 m | DIN Rail | No Certification | ~0.255 kg | Basic certified-free variant |

| 330850-90-05 | 9.0 m | Panel Mount | Multi-Approved | ~0.5 kg | Extended length version |

| 330850-91-05 | 9.0 m | DIN Rail | Multi-Approved | ~0.5 kg | DIN version of extended system |

| 330850-50-00 | 5.0 m | Panel Mount | No Certification | ~0.1 kg | Lowest-cost variant, unapproved version |

🌟 5 Popular Models from the Same Brand (Bently Nevada)

| Model | Type / Function | Key Feature | Applications |

|---|---|---|---|

| 330105-02-12-05-02-00 | Proximitor Probe System | Configurable proximity probe assembly | Shaft monitoring with 3300 systems |

| 3500/05-01-01-00-00 | Monitoring System Chassis | Part of the 3500 Series with slot-based design | Centralized vibration systems |

| 9200-03-05-10-00 | Intelligent Monitoring Sensor | High-speed data output for IIoT and analytics | Remote asset diagnostics |

| 176449-03 | Signal Conditioning Module | Supports signal interface and data conversion | System integration setups |

| 330500 Velomitor | Velocity Vibration Transducer | Converts vibration into voltage output | Used in critical rotating machines |

❓ 10 FAQs – Bently Nevada 330850-51-05

Q1: What components are needed for this sensor to function properly?

A1: It requires a compatible 3300 XL 25 mm proximity probe and extension cable. Together with the proximitor sensor, they form a complete measuring chain.

Q2: Can this model replace older 3300 systems?

A2: Yes, the 3300 XL series is designed with backward compatibility in mind, allowing for integration or upgrades with older systems. Always verify voltage, cable length, and connector type before replacement.

Q3: Is this sensor suitable for EMI/RFI-heavy environments?

A3: Absolutely. It includes enhanced electromagnetic immunity and complies with international EMC standards, making it suitable for high-noise industrial settings.

Q4: What voltage does it need to operate?

A4: It requires –17.5 to –26 VDC without isolation and –23 to –26 VDC with isolation components. Voltage outside this range may affect performance or linearity.

Q5: Can it work under extreme temperature conditions?

A5: Yes. The operating temperature range is –35°C to +85°C, with storage capability down to –51°C and up to +100°C.

Q6: Does shaft material affect measurement accuracy?

A6: Yes. The proximity system is calibrated for standard materials like AISI 4140. For other materials (e.g., stainless steel), correction factors should be applied.

Q7: What’s the recommended gap between the probe and shaft?

A7: Maintain the probe within the specified linear range (typically 0.25 to 12.5 mm) and avoid contact. Installation clearance should factor in thermal expansion and shaft movement.

Q8: What’s required during maintenance or recalibration?

A8: Disconnect power, use the proper calibration tools, and document the settings. Ensure compatibility when replacing cables or probes and check signal integrity post-calibration.

Q9: How can I handle longer cable runs or distance?

A9: Consider models with longer system lengths (e.g., 9 m options like 330850-90-05) and ensure shielded cables are used to maintain signal quality over distance.

Q10: How long can this device last in the field?

A10: With proper installation and routine inspections, these sensors can last for 5–10+ years. Lifespan depends on environment, vibration levels, and electrical stress.