ProductPRODUCT

Featured products

Contact Us

- Bently Nevada

- 330103-00-16-50-12-RU

- 3300 XL 8 mm Proximity Probe

- USA

- 230 mm x 190 mm x 70 mm

- 4kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 44

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Bentley Nevada 330103-00-16-50-12-RU – Product Overview, Applications, Advantages, and Related Models

Product Overview

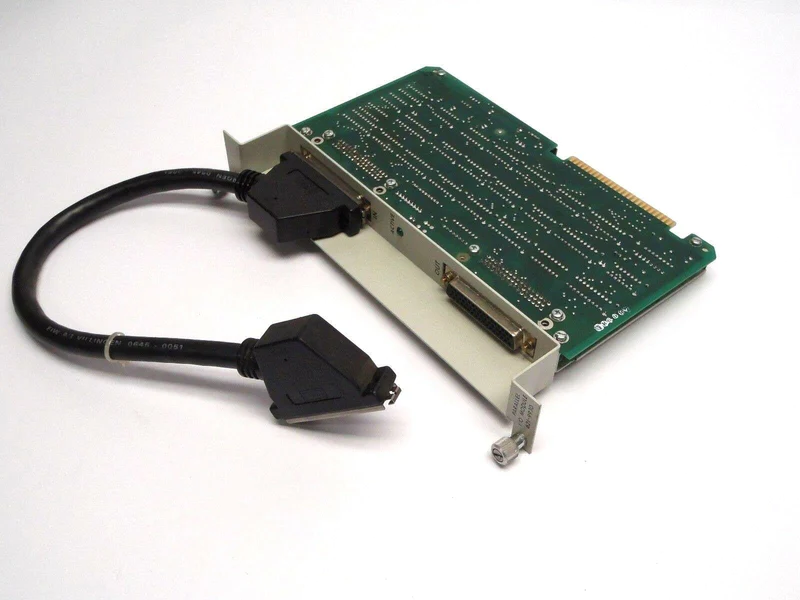

The Bentley Nevada 330103-00-16-50-12-RU is an advanced vibration monitoring module designed for use in critical machinery health monitoring systems. It is specifically engineered to monitor rotating equipment, detecting early signs of mechanical faults such as misalignment, unbalance, or bearing wear. This model is part of the Bentley Nevada Vibration Monitoring Systems, which are renowned for providing reliable and real-time diagnostics for machinery in industrial applications. The 330103-00-16-50-12-RU is ideal for industries where minimizing downtime and preventing equipment failure is crucial, including power generation, oil and gas, manufacturing, and chemical processing.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | Bentley Nevada 330103-00-16-50-12-RU |

| Operating Voltage | 24V DC |

| Frequency Range | 4-20 mA Output |

| Temperature Range | -40°C to +85°C |

| Dimensions | 230 mm x 190 mm x 70 mm |

| Weight | 4.0 kg |

| Mounting Type | Wall or Rack Mountable |

| Signal Output | Analog and Digital Output |

| Power Consumption | 5W |

| Communication | RS-485, Modbus RTU |

| Enclosure | IP65 |

Product Introduction

The Bentley Nevada 330103-00-16-50-12-RU is a highly efficient vibration monitoring system that offers real-time data for rotating machinery health monitoring. Designed to operate in harsh industrial environments, this model is capable of identifying potential issues before they lead to major failures. Its ability to detect subtle changes in vibration patterns provides early warning signs of mechanical faults, helping to avoid costly repairs and downtime. This device is commonly used in industries that rely on the continuous operation of heavy machinery, such as power plants, oil rigs, manufacturing lines, and chemical plants.

Applications

The Bentley Nevada 330103-00-16-50-12-RU is used in a variety of industrial sectors where machinery performance and uptime are critical. Key applications include:

-

Power Generation – Monitoring turbines, compressors, and generators to prevent unexpected failures and optimize plant performance.

-

Oil and Gas – Keeping offshore platforms, pumps, and compressors running smoothly to avoid costly interruptions and safety hazards.

-

Manufacturing – Ensuring the smooth operation of production equipment, such as motors, conveyors, and cooling systems.

-

HVAC Systems – Monitoring HVAC components like blowers and fans, preventing system failures during critical heating and cooling cycles.

-

Water Treatment – Monitoring pumps and motors in water treatment plants to ensure continuous operation and efficient water management.

Advantages

-

Early Fault Detection: The 330103-00-16-50-12-RU is designed to detect mechanical issues at the earliest stages, such as misalignment or imbalance, helping to prevent catastrophic equipment failures.

-

Real-Time Monitoring: The device offers continuous monitoring, providing operators with up-to-date data on machinery health, so that issues can be addressed before they escalate.

-

Durability: Built with an IP65-rated enclosure, this system is designed to withstand harsh conditions, such as high humidity, dust, and extreme temperatures.

-

Cost-Efficiency: By enabling predictive maintenance, the system helps companies avoid the high costs associated with unplanned downtime and emergency repairs.

-

Versatility: The system supports both analog and digital outputs, which ensures easy integration into existing machinery monitoring setups.

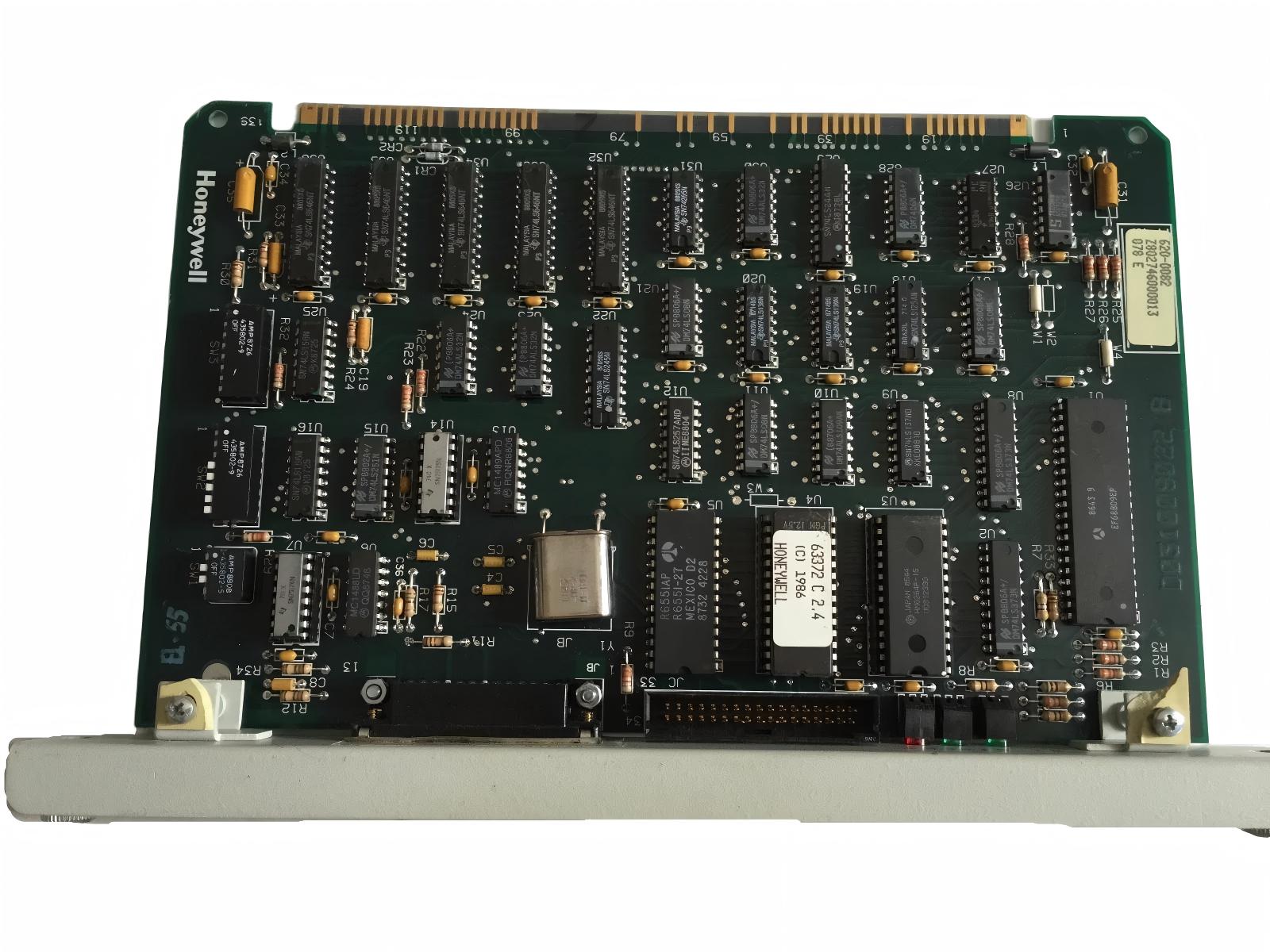

Brand and Series

-

Brand: Bentley Nevada

-

Series: Vibration Monitoring Systems

Bentley Nevada is a leading manufacturer of machinery health monitoring and predictive maintenance systems. The 330103-00-16-50-12-RU is part of the Vibration Monitoring Systems series, which is known for providing precise, reliable, and real-time diagnostics for the health of critical industrial machinery.

Recommended Models in the Same Series

Here are five other models from the Bentley Nevada series or related models that offer similar functionality and capabilities:

| Model | Description | Specifications |

|---|---|---|

| 330103-00-16-50-12-01 | Vibration Monitoring System | Similar to the 330103-00-16-50-12-RU, with different signal output configurations. |

| 330103-00-16-50-12-02 | Vibration Monitoring for Turbines | Enhanced performance for high-speed turbine monitoring. |

| 330103-00-16-50-12-04 | Multi-Channel Vibration Sensor | Provides simultaneous monitoring for multiple machines. |

| 330103-00-16-50-12-05 | Vibration Monitoring for Pumps | Specialized for pump monitoring with a high-frequency response. |

| 330103-00-16-50-12-06 | Industrial Vibration Monitoring System | Compact model designed for smaller, space-constrained setups. |

Recommended Models from Bentley Nevada

Here are five popular models from Bentley Nevada, known for their reliability and precision in vibration monitoring:

| Model | Description | Specifications |

|---|---|---|

| 3500/42M | Vibration Monitoring for machinery | 24V DC, 4-20 mA output, temperature range -40°C to +70°C |

| 3500/22M | Multi-channel monitoring system for motors | Supports real-time data acquisition for multiple machines |

| 330700 | Vibration sensor for pumps and turbines | High sensitivity, wide frequency range, and easy integration |

| 3500/15 | Machinery protection system | Features RS-485 communication, providing fast diagnostics |

| 3500/50M | Vibration analysis for large machinery | Designed for large-scale machinery with advanced signal processing |

FAQ (Frequently Asked Questions)

Q1: What types of equipment can be monitored with the Bentley Nevada 330103-00-16-50-12-RU?

A1: This model is designed to monitor critical rotating machinery such as turbines, compressors, motors, pumps, and other equipment in industrial settings.

Q2: How does the Bentley Nevada 330103-00-16-50-12-RU detect faults in machinery?

A2: The system monitors vibration frequencies and amplitudes. Deviations from normal vibration patterns indicate mechanical issues, such as misalignment or imbalance, which are early signs of potential failure.

Q3: Can the Bentley Nevada 330103-00-16-50-12-RU be used in extreme environments?

A3: Yes, the system is designed to operate in extreme environments, with an operating temperature range from -40°C to +85°C and an IP65-rated enclosure that protects it from dust and moisture.

Q4: What is the advantage of using this model for machinery health monitoring?

A4: This model provides early fault detection, allowing operators to perform maintenance before a major failure occurs, thus minimizing downtime and reducing maintenance costs.

Q5: Can this model be integrated into existing machinery monitoring systems?

A5: Yes, the Bentley Nevada 330103-00-16-50-12-RU supports both analog and digital output, making it compatible with most existing control systems.

Q6: Is this system suitable for large-scale industrial applications?

A6: Yes, the Bentley Nevada 330103-00-16-50-12-RU is ideal for both large-scale and smaller industrial setups, providing scalable solutions for a variety of machinery monitoring needs.

Q7: What industries commonly use the Bentley Nevada 330103-00-16-50-12-RU?

A7: This system is used across various industries, including power generation, oil and gas, manufacturing, HVAC, and water treatment, where rotating machinery plays a critical role.

Q8: How does the real-time monitoring feature benefit operations?

A8: Real-time monitoring allows for continuous assessment of machinery health, enabling prompt detection of issues and allowing for faster response times to prevent failures.

Q9: How long can I expect the Bentley Nevada 330103-00-16-50-12-RU to last?

A9: With proper maintenance and care, the Bentley Nevada 330103-00-16-50-12-RU can provide reliable service for many years, typically over 10 years, depending on usage conditions.

Q10: What type of maintenance is required for the Bentley Nevada 330103-00-16-50-12-RU?

A10: The system requires minimal maintenance. Regular inspections to ensure the sensors are clean and free of debris, as well as ensuring that connections are secure, are recommended.