ProductPRODUCT

Featured products

Contact Us

- Honeywell

- 620-0082

- Diagnostics Interface Module

- USA

- 230 × 120 × 60 mm

- 1.1kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 5

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

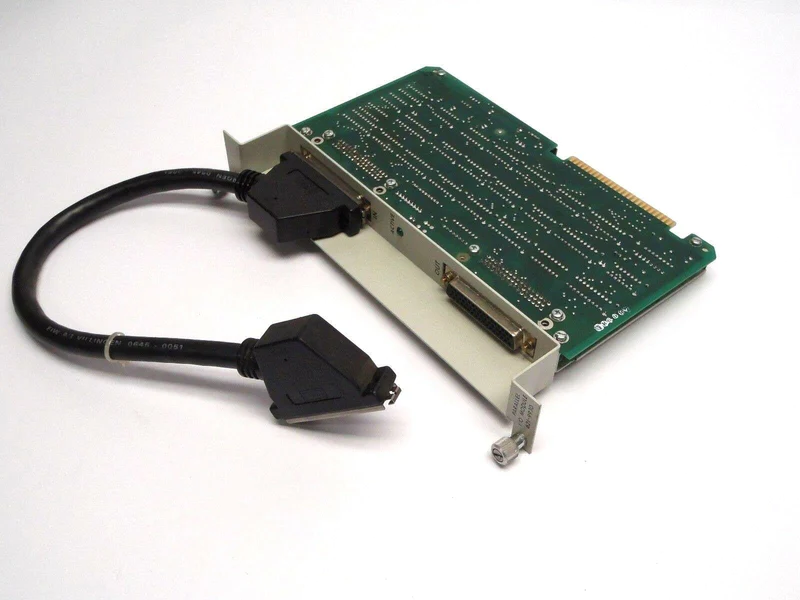

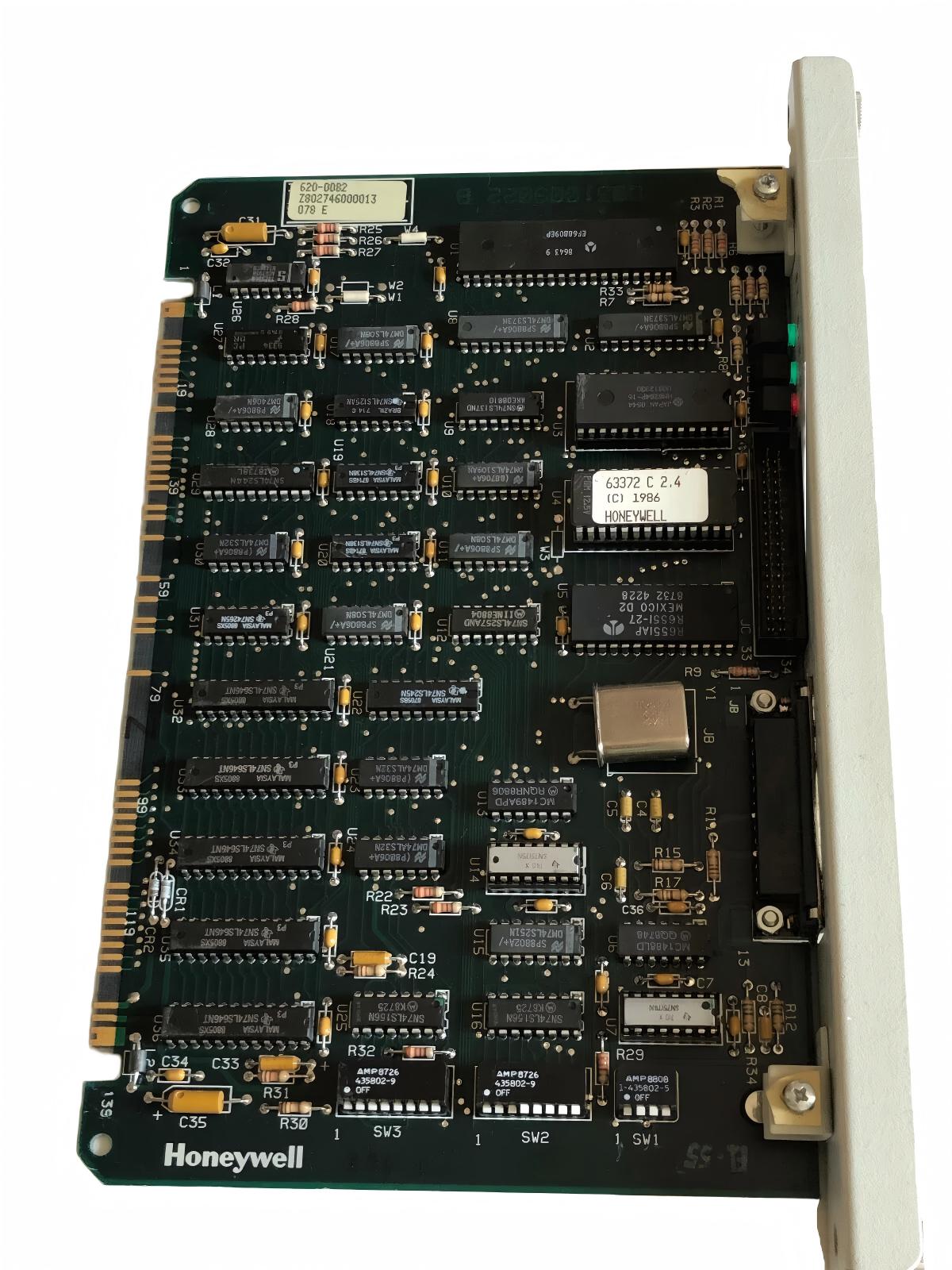

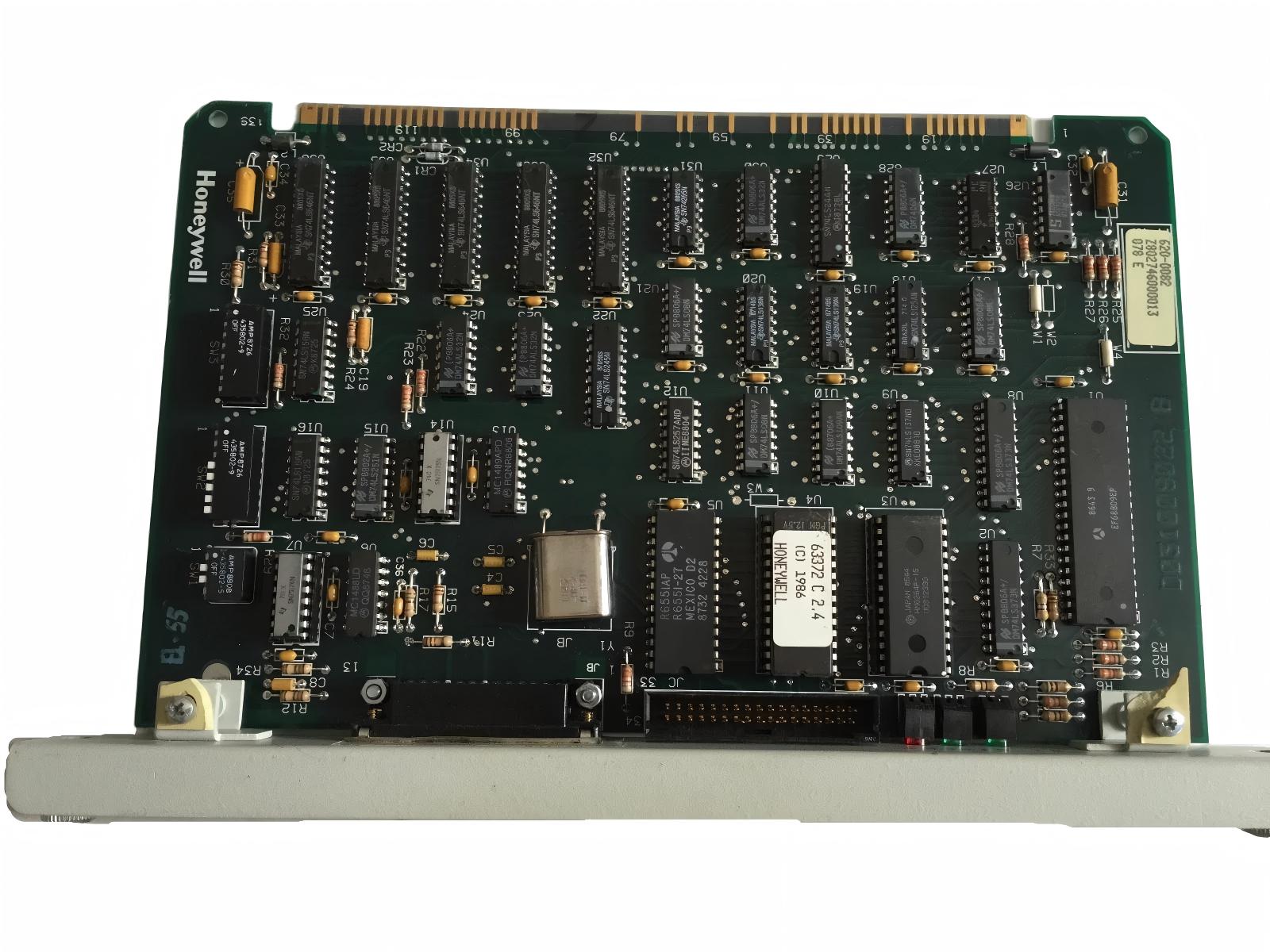

Honeywell 620‑0082 PLC Interface and Control Module

Product Basic Information

-

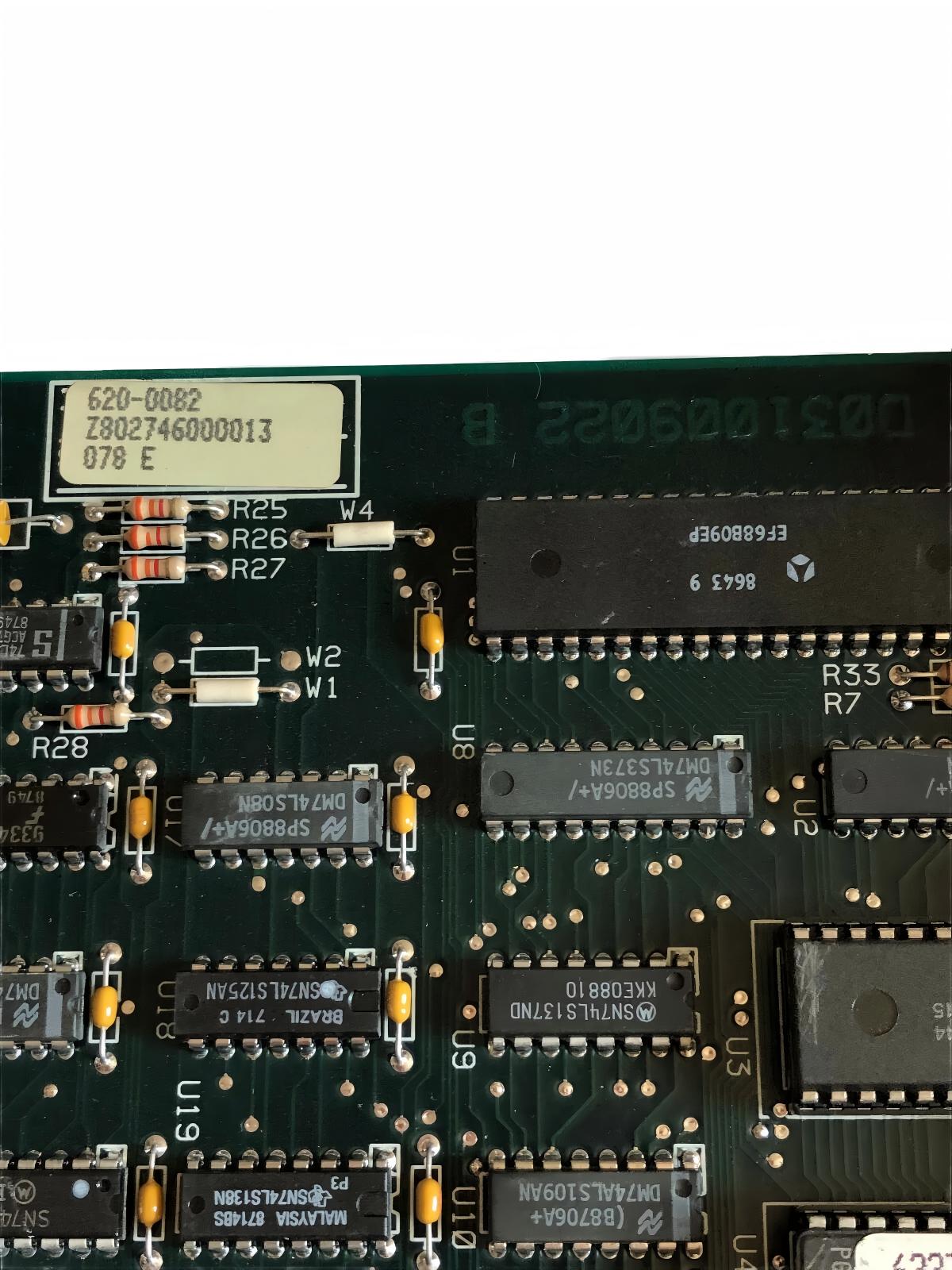

Model: 620‑0082

-

Product Type: PLC Interface and Control Module

-

Brand: Honeywell

-

Series: IPC 620 PLC Module Series

-

Category: Industrial Automation / PLC Interface & Control

Product Introduction

The 620‑0082 module is an industrial‑grade programmable logic controller (PLC) interface and control module designed to operate within modular automation systems built around the IPC 620 series architecture.

Its primary function is to handle real‑time system logic control and communication between the central processing unit and distributed I/O modules, sensors, and actuators within a PLC rack. The 620‑0082 has been engineered to deliver lasting performance in continuous duty environments where stable logic execution and communication integrity are essential.

This module combines reliable control processing with flexible interface capabilities, making it suitable for a wide range of automation tasks where modular expansion and dependable operation are priorities. Its rugged design allows it to endure typical industrial conditions such as temperature variations, vibration, and electrical noise.

Product Applications

The 620‑0082 is applied in industrial control and automation systems requiring reliable logic processing and interface coordination. Typical application scenarios include:

-

Multi‑rack PLC installations for large‑scale manufacturing lines.

-

Continuous process control in energy, chemical, or petrochemical facilities.

-

Integration with distributed I/O for machine control, safety interlocks, or sensor networks.

-

Modular expansions where new control channels or interface capabilities are required.

-

Replacement of aging interface modules in existing PLC systems.

This module’s architecture supports stable communication between control layers and field‑level devices, enabling consistent operation across complex control hierarchies.

Product Advantages

The 620‑0082 module offers several significant industrial advantages:

-

Reliable Logic Control: Designed for deterministic execution of automation logic with minimal variance.

-

Robust Communication: Facilitates stable interfaces with peripheral modules, I/O points, and sensors.

-

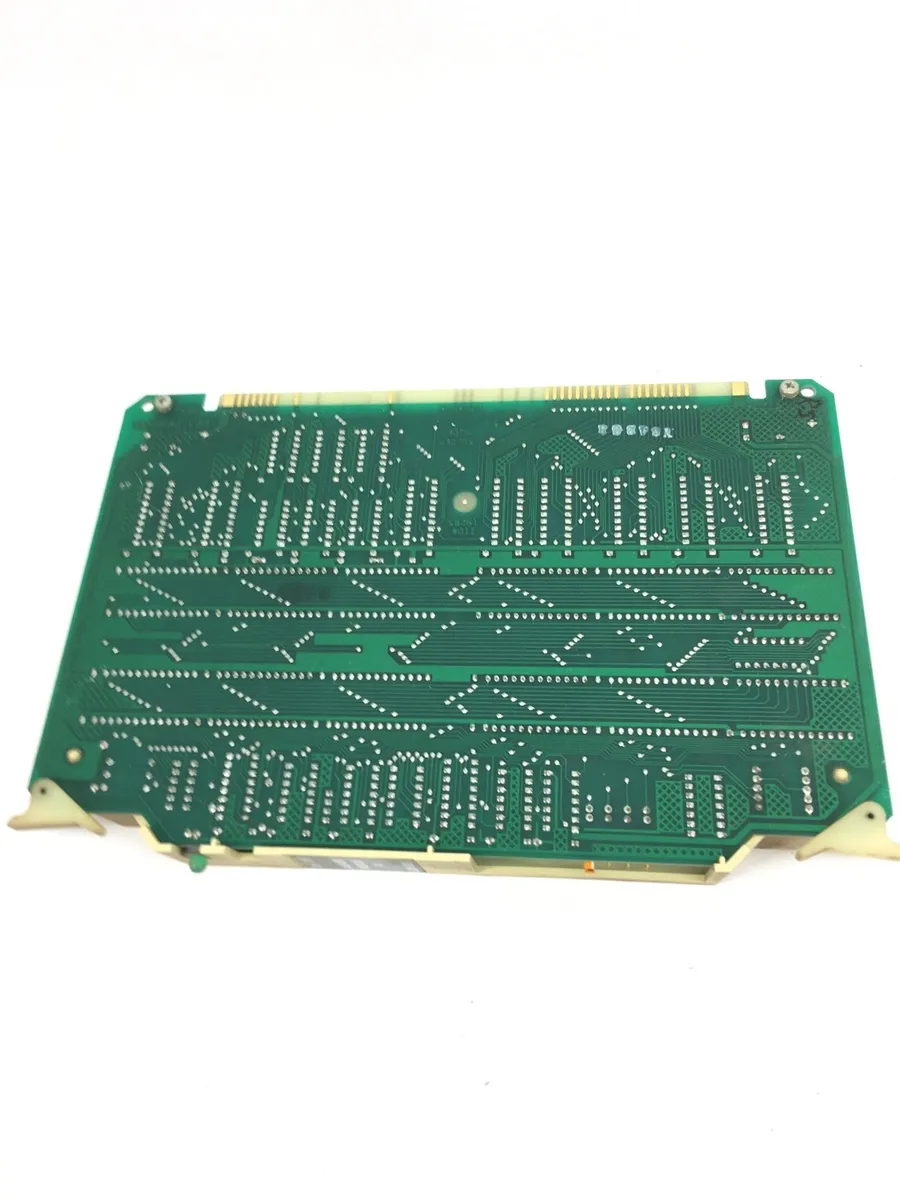

Industrial Durability: Constructed to withstand vibration, temperature shifts, and electrical interference typical of industrial settings.

-

Modular Flexibility: Rack‑mount form factor allows easy insertion, replacement, and future system expansion.

-

Diagnostic Visibility: Integral LEDs provide immediate visual feedback for operational status, faults, and communication activity.

-

Long Service Life: Engineered to maintain performance over extended duty cycles with minimal maintenance.

These advantages make the 620‑0082 suitable for demanding automation tasks where reliability and performance are critical.

Product Specifications

| Parameter | Description |

|---|---|

| Model | 620‑0082 |

| Product Type | PLC interface and control module |

| Core Function | Real‑time logic control with communication management |

| Compatible Platform | IPC 620 PLC systems |

| Installation Method | Rack‑mounted plug‑in module |

| Rated Voltage | 115 / 230 VAC |

| Processor Architecture | Industrial PLC processor |

| Memory | Non‑volatile program memory |

| Operational Mode | Deterministic real‑time control |

| Operating Temperature | 0°C to 55°C |

| Storage Temperature | ‑20°C to 70°C |

| Relative Humidity | 5% to 95% non‑condensing |

| Diagnostic Indicators | Status, run, fault, communication LEDs |

| Dimensions | 230 × 120 × 60 mm |

| Weight (kg) | 1.10 kg |

Recommended Models – Same Series or Related Modules

Below are five modules from the same IPC 620 PLC family or related interface/control modules that serve similar or complementary roles:

| Model | Description | Dimensions | Weight (kg) |

|---|---|---|---|

| 620‑0086 | Parallel link driver and interface module | 220 × 120 × 60 mm | 0.90 kg ( ) |

| 620‑0088 | Communication interface module | 225 × 125 × 60 mm | 0.95 kg ( ) |

| 620‑0052 | Control processor and interface module | 250 × 140 × 70 mm | 1.50 kg ( ) |

| 620‑0057 | Integrated control and communication module | 250 × 140 × 70 mm | 1.50 kg ( ) |

| 620‑0038 | Processor interface module | 245 × 135 × 65 mm | 1.40 kg ( ) |

Recommended Popular Models – Same Brand

Below are five popular automation and control models from the same brand that are widely used in industrial control environments:

| Model | Product Type | Dimensions | Weight (kg) |

|---|---|---|---|

| 900G‑01 | PLC CPU / Central Processing Module | 240 × 140 × 65 mm | 1.20 kg ( ) |

| 900H‑02 | High‑Capacity I/O Controller | 260 × 150 × 70 mm | 1.40 kg ( ) |

| 900P‑05 | Industrial Power Supply Module | 180 × 120 × 60 mm | 0.90 kg ( ) |

| 900C‑10 | Communication Gateway Module | 220 × 130 × 65 mm | 1.00 kg ( ) |

| 900R‑08 | Redundant Control / Backup Module | 250 × 150 × 70 mm | 1.50 kg ( ) |

Frequently Asked Questions (FAQ)

Q1: What is the main purpose of the 620‑0082 module?

A1: It provides real‑time logic control and communication interfacing for distributed industrial automation systems.

Q2: Which PLC platforms support this module?

A2: The 620‑0082 is designed for modular IPC 620 series programmable logic controller platforms.

Q3: Can the 620‑0082 operate continuously in industrial environments?

A3: Yes, it is designed for continuous industrial operation with stable performance.

Q4: Does the module include diagnostic indicators?

A4: Yes, it features LED indicators for status, run, fault, and communication activity.

Q5: Is installation and replacement straightforward?

A5: Yes, its standardized rack‑mount plug‑in design allows easy installation and field replacement.

Q6: What types of signals does the module support?

A6: It supports digital logic signals and communication interfaces appropriate for control modules and I/O subsystems.

Q7: Does this module require special cooling?

A7: No special cooling is required; normal rack ventilation is sufficient.

Q8: Can it operate in high‑humidity industrial areas?

A8: Yes, it supports a relative humidity range of 5% to 95% non‑condensing.

Q9: Is the 620‑0082 suitable for system expansions?

A9: Yes, it supports modular expansion within the IPC 620 PLC series architecture.

Q10: What is the expected lifespan of this module in industrial duty?

A10: With proper installation and maintenance, it is engineered to provide long‑term reliable operation.