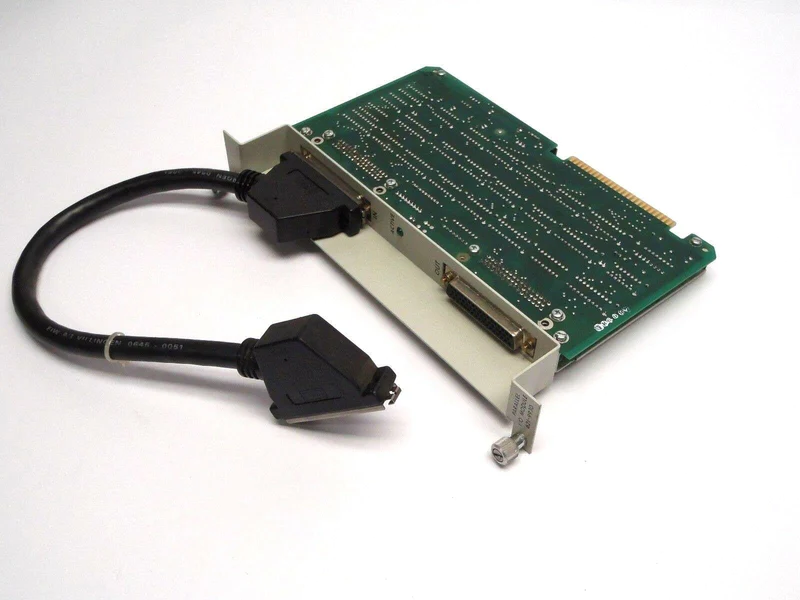

ProductPRODUCT

Featured products

Contact Us

- Bently Nevada

- 330103-00-16-10-12-RU

- 3300 XL 8 mm Proximity Probe

- USA

- 200 mm x 150 mm x 70 mm

- 3.8kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 33

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Bentley Nevada 330103-00-16-10-12-RU – Product Overview, Applications, Advantages, and Related Models

Product Overview

The Bentley Nevada 330103-00-16-10-12-RU is an advanced vibration monitoring and diagnostics system used for monitoring rotating machinery and industrial equipment. This product is part of the Bentley Nevada series, known for providing high-precision data used in predictive maintenance and machinery health monitoring. The 330103-00-16-10-12-RU model is designed to deliver highly reliable real-time condition monitoring data for critical machinery. By offering both analog and digital outputs, it is compatible with various control systems, providing versatility across different industrial applications. This model is particularly useful in industrial sectors such as power generation, oil and gas, manufacturing, and HVAC systems, where machinery uptime is essential.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | Bentley Nevada 330103-00-16-10-12-RU |

| Operating Voltage | 24V DC |

| Frequency Range | 4-20 mA Output |

| Temperature Range | -40°C to +85°C |

| Dimensions | 200 mm x 150 mm x 70 mm |

| Weight | 3.8 kg |

| Mounting Type | Wall or Rack Mountable |

| Signal Output | Analog and Digital Output |

| Power Consumption | 5W |

| Communication | RS-485, Modbus RTU |

| Enclosure | IP65 |

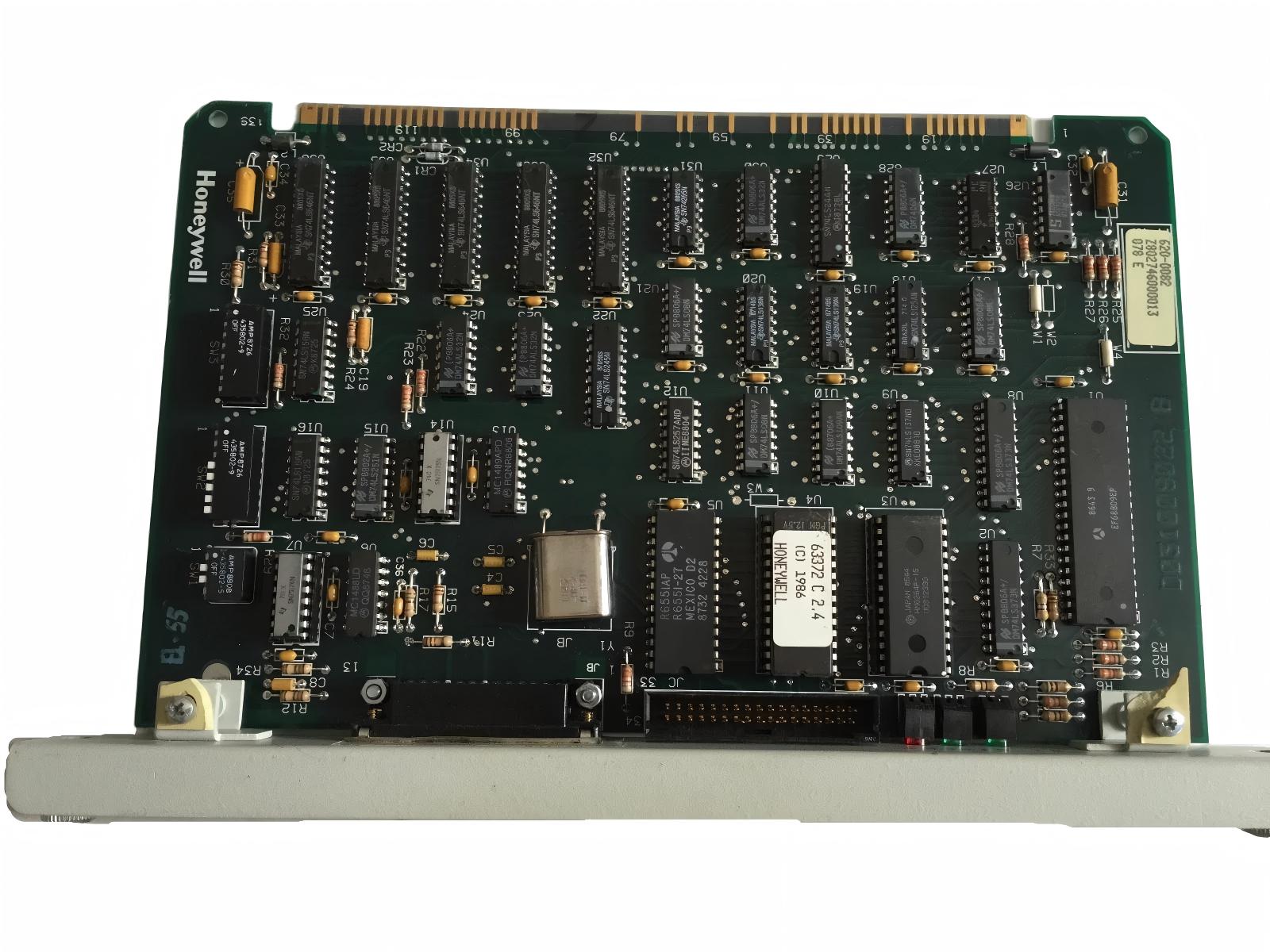

Product Introduction

The Bentley Nevada 330103-00-16-10-12-RU is part of the Vibration Monitoring Systems family and is specifically designed to monitor rotating equipment such as turbines, compressors, and motors. It offers real-time feedback and early detection of mechanical faults like misalignment, imbalance, and bearing issues. This allows maintenance teams to schedule repairs before failures occur, thus minimizing downtime and maximizing equipment lifespan. The 330103-00-16-10-12-RU is built to withstand extreme industrial environments, providing consistent, accurate data for monitoring critical machinery across various sectors.

Applications

The Bentley Nevada 330103-00-16-10-12-RU can be used in a wide range of industrial applications, particularly in situations where the condition of rotating equipment needs to be constantly monitored. Here are the main applications:

-

Power Generation – Monitoring turbines, generators, and other critical power plant equipment.

-

Oil and Gas – Ensuring the health of pumps, compressors, and motors in offshore platforms and refineries.

-

Manufacturing – Vibration analysis for motors, conveyors, and other machinery used in production lines.

-

HVAC Systems – Monitoring large fans, blowers, and pumps in commercial and industrial HVAC systems.

-

Water Treatment – Keeping track of pumps and other equipment in water treatment facilities.

Advantages

-

Early Fault Detection: The 330103-00-16-10-12-RU provides advanced fault detection capabilities, helping users spot issues like unbalance and misalignment before they lead to costly downtime or repairs.

-

Durability: Built with a robust IP65-rated enclosure, the system can withstand harsh environmental conditions, making it suitable for industrial applications that involve exposure to dust, moisture, and high temperatures.

-

Real-Time Data: The system provides real-time data, enabling operators to monitor the health of machinery continuously and respond quickly to potential issues.

-

Ease of Integration: The model supports both analog and digital output, ensuring compatibility with various industrial control and monitoring systems.

-

Cost-Efficiency: By offering predictive maintenance capabilities, the Bentley Nevada 330103-00-16-10-12-RU helps reduce unnecessary maintenance costs and unplanned downtime.

Brand and Series

-

Brand: Bentley Nevada

-

Series: Vibration Monitoring Systems

Bentley Nevada is a world leader in the field of machinery health monitoring and predictive maintenance. Their systems are widely trusted across industries for providing critical information regarding the health of rotating equipment. The 330103-00-16-10-12-RU is part of their well-regarded Vibration Monitoring Systems series, offering highly reliable data collection and analysis for proactive maintenance management.

Recommended Models in the Same Series

Below are five other models from the Bentley Nevada series or related models that provide similar features and capabilities:

| Model | Description | Specifications |

|---|---|---|

| 330103-00-16-10-12-03 | Vibration Monitoring System | Similar to the 330103-00-16-10-12-RU, with slight differences in frequency response range. |

| 330103-00-16-10-12-04 | Vibration Sensor | Enhanced signal processing and diagnostics for rotating equipment. |

| 330103-00-16-10-12-05 | Industrial Vibration Monitoring | Compact form factor designed for tight spaces. |

| 330103-00-16-10-12-06 | Advanced Vibration Analysis System | Offers multi-channel monitoring for large setups. |

| 330103-00-16-10-12-07 | Machinery Health Monitoring | Supports higher bandwidth frequencies for precision monitoring. |

Recommended Models from Bentley Nevada

Here are five popular models from Bentley Nevada that are known for their reliability and performance in the field of vibration monitoring:

| Model | Description | Specifications |

|---|---|---|

| 3500/42M | Vibration Monitoring for machinery | 24V DC, 4-20 mA output, temperature range -40°C to +70°C |

| 3500/22M | Multi-channel monitoring system for motors | Analog and digital output, precise data collection |

| 330700 | Vibration sensor for pumps and turbines | Wide frequency range, high sensitivity for fault detection |

| 3500/15 | Machinery protection system | Compact design with RS-485 communication support |

| 3500/50M | Vibration analysis for large machinery | Real-time diagnostics with enhanced signal processing |

FAQ (Frequently Asked Questions)

Q1: What kind of equipment can the Bentley Nevada 330103-00-16-10-12-RU monitor?

A1: It is used for monitoring rotating machinery such as turbines, compressors, pumps, and motors in industries like power generation, oil and gas, and manufacturing.

Q2: What are the key features of the Bentley Nevada 330103-00-16-10-12-RU?

A2: The main features include real-time vibration monitoring, early fault detection, analog and digital outputs, and a rugged IP65-rated enclosure for industrial environments.

Q3: How does this system help in predictive maintenance?

A3: The system continuously monitors equipment for signs of potential failure, such as imbalance or misalignment, allowing operators to take action before a failure occurs.

Q4: Is this product easy to install?

A4: Yes, it is designed for easy installation with options for wall or rack mounting, and it can integrate seamlessly with existing monitoring systems via RS-485 or Modbus RTU communication.

Q5: Can this product operate in extreme temperatures?

A5: Yes, it can operate in a wide temperature range of -40°C to +85°C, making it suitable for a variety of industrial environments.

Q6: Can the Bentley Nevada 330103-00-16-10-12-RU be used with other monitoring systems?

A6: Yes, it supports both analog and digital output, making it compatible with a wide range of control and monitoring systems used in industrial applications.

Q7: What industries typically use this product?

A7: It is used across industries such as power generation, oil and gas, manufacturing, HVAC, and water treatment.

Q8: Does the Bentley Nevada 330103-00-16-10-12-RU require constant maintenance?

A8: The system is designed for minimal maintenance. Regular checks are recommended to ensure optimal performance, but it is built for long-term use in harsh environments.

Q9: How does the Bentley Nevada 330103-00-16-10-12-RU communicate with other equipment?

A9: It uses RS-485 communication and Modbus RTU protocols, which are industry standards for industrial equipment.

Q10: How accurate is the data provided by the Bentley Nevada 330103-00-16-10-12-RU?

A10: The system provides highly accurate vibration data, allowing operators to detect faults with high precision, which is crucial for effective predictive maintenance.