ProductPRODUCT

Featured products

Contact Us

- Bently Nevada

- 3300/16-12-01-03-000

- Dual Vibration Monitor Module

- USA

- 198 mm × 162 mm × 108 mm

- 1.2kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 93

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| sales@plc-automations.com | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

1. Product Overview — Bently Nevada 3300/16‑12‑01‑03‑000

Introduction

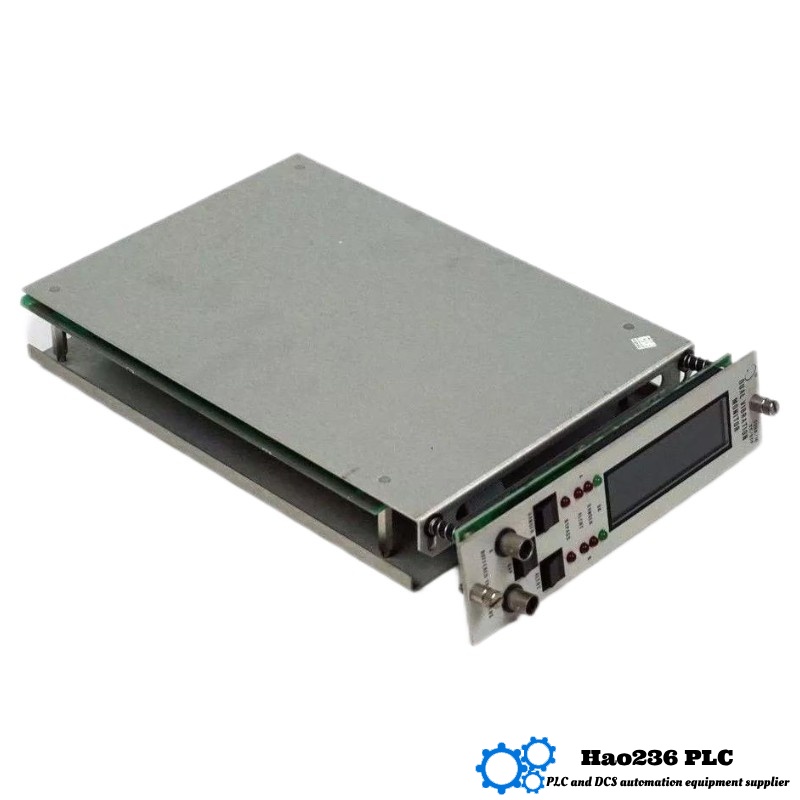

The 3300/16‑12‑01‑03‑000 is a dual-channel vibration monitor in the 3300 series monitoring system. It processes inputs from two proximity probe / Proximitor sensor chains, monitoring radial vibration in two directions (X/Y) and average shaft position (gap). The “16” prefix denotes the dual vibration (XY/gap) monitor variant. The suffix “12‑01‑03‑000” captures internal configuration (scale, alarm modules, barrier presence, etc.).

This module is designed to fit into a 3300 monitor rack, offering continuous online machinery protection compliant with API-670 style demands. It replaces older 3300/15 monitors by adding radial position (gap) alarm capability and flexible digital setpoints.

2. Technical Specifications

| Parameter | Specification / Typical Value |

|---|---|

| Model | 3300/16‑12‑01‑03‑000 |

| Type / Category | Dual Vibration Monitor (XY + Gap) |

| Channels | 2 (radial vibration + shaft gap) |

| Input Signal | Proximitor (eddy-current proximity) sensor chains |

| Full-scale Vibration Range | Up to 500 mm/s (typical) |

| Power Supply | 95–125 VAC or 190–250 VAC (switchable) |

| Dimensions (W × H × D) | 198 mm × 162 mm × 108 mm (19.8 cm × 16.2 cm × 10.8 cm) |

| Weight | ~1.2 kg (1,200 g) |

| Operating Temperature | –20°C to +65°C (typical) |

| Storage Temperature | –40°C to +85°C |

| Alarm Modules | Onboard or slot for relays (configurable) |

| Digital Setpoints | User-programmable alarm and danger thresholds |

| Display / Indicators | LCD bar-graph, LED status indicators (OK, Bypass, Alert, Danger) |

| Internal Barriers | Safety / intrinsic isolation circuits (depending variant) |

| Certification / Compliance | CE, API-compatible for machinery protection |

3. Applications

The 3300/16 dual vibration monitor is typically used in:

-

Turbine and generator rotor monitoring

-

Industrial compressors, pumps, motors

-

Gearboxes and large rotating assemblies

-

API 670-style machinery protection systems

-

Critical asset monitoring where dual-channel vibration + gap detection is needed

-

Retrofit of older 3300/15 systems to add gap alarm capability

4. Advantages & Key Features

-

Dual-channel capability: Simultaneous vibration (X/Y) and gap measurement

-

Gap alarm logic: Adds rotor position (gap) thresholds beyond mere vibration alarms

-

Digital setpoints: User-adjustable alarm / danger levels for flexibility

-

Modular design: Fits into standard 3300 racks, easy to replace or upgrade

-

Visual feedback: LCD and LED indicators support quick diagnostics

-

Adaptable input: Works with standard proximitor sensor chains

-

Compliant format: Designed to satisfy API-style machinery protection needs

-

Solid mechanical design: Supports rugged industrial use

5. Related / Same‑Series or Variant Models

| Model | Type / Variant | Dimensions / Weight | Notes / Differences |

|---|---|---|---|

| 3300/16‑12‑01‑01 | Dual vibration monitor variant “01” | 19.8 × 16.2 × 10.8 cm, ~1.2 kg | Base version with fewer alarm options |

| 3300/16‑12‑01‑02 | Dual vibration monitor “02” variant | Similar dimensions, ~1.2 kg | Possibly includes additional relays |

| 3300/16‑12‑01‑03 | The model above (XY + Gap) | 19.8 × 16.2 × 10.8 cm, ~1.2 kg | Adds gap (position) capability |

| 3300/16‑13‑01‑01 | 16-series variant with alternate input | ~same footprint | Slight internal configuration difference |

| 3300/16‑15‑01‑03 | Enhanced 16-series variant | similar footprint, ~1.2 kg | High range / extra features variant |

6. Popular Models from the Same Brand

| Model | Type / Function | Typical Use | Notes |

|---|---|---|---|

| 3500/05‑01‑01‑00‑00 | Monitoring rack / module | Multi-channel vibration monitoring | Core rack for modern machinery systems |

| 9200/03/05/10/00 | Smart monitoring module | Remote diagnostics / IIoT integration | Digital / network-enabled module |

| 330105‑02‑12‑05 | Proximity probe + extension cable | Shaft displacement sensing | Typical sensor front-end unit |

| 330500 Velocity Sensor | Vibration velocity transducer | Velocity-based vibration measurement | Often paired with displacement sensors |

| 330450‑10‑05 | Compact probe assembly | Tight-space sensor placement | Useful where space is constrained |

7. FAQs (Q & A)

Q1: What does “3300/16” designate?

A1: It denotes a dual‑channel vibration monitor (X/Y + gap) in the 3300 series.

Q2: What is the weight of the module?

A2: Approximately 1.2 kg.

Q3: What are the dimensions?

A3: 198 × 162 × 108 mm (19.8 cm × 16.2 cm × 10.8 cm).

Q4: Which sensors can it interface with?

A4: It supports standard proximity probe / Proximitor sensors in the 3300 ecosystem.

Q5: What is the operating temperature range?

A5: –20°C to +65°C.

Q6: What additional function does 3300/16 have over earlier monitors?

A6: It adds gap (shaft position) alarm capability beyond vibration-only alarms.

Q7: Are the alarm setpoints adjustable?

A7: Yes, digital user-configurable alarm and danger thresholds.

Q8: Does it include internal safety barriers?

A8: It may contain isolation/barrier circuits depending on variant.

Q9: What power inputs are supported?

A9: 95–125 VAC or 190–250 VAC switchable.

Q10: How are status and diagnostics provided?

A10: Via LCD bar-graph display and LED indicators (OK, Bypass, Alert, Danger).

Authenticity guarantee

All product specifications are original and authentic imported products. We have an annual sales volume of 300 million yuan, and we only produce original and authentic products. All customers who cooperate with us directly online can enjoy low discounts.

Free warehouse

We have a complete range of product models, 80% of conventional models are in stock, and we have established channels in Asia, Africa, North America, South America, and Europe, effectively shortening the order processing time and satisfying customers in a timely manner.

Technical Team

Fast delivery. Spot goods can be shipped on the same day, and the delivery time transaction is 20% faster than that of peers on average, with a delivery time accuracy rate of 99%.

Thoughtful after-sales service

24-hour after-sales service guarantee team, professional and standardized management service system.