ProductPRODUCT

Featured products

Contact Us

- ABB

- CP630

- Control Panel

- Sweden

- 180 mm × 120 mm × 85 mm

- 2.3kg

- 1SAP530100R0001

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 8

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

ABB CP630 (1SAP530100R0001) — Detailed Product Specification, Introduction, Applications, Advantages, and FAQ

Product Overview

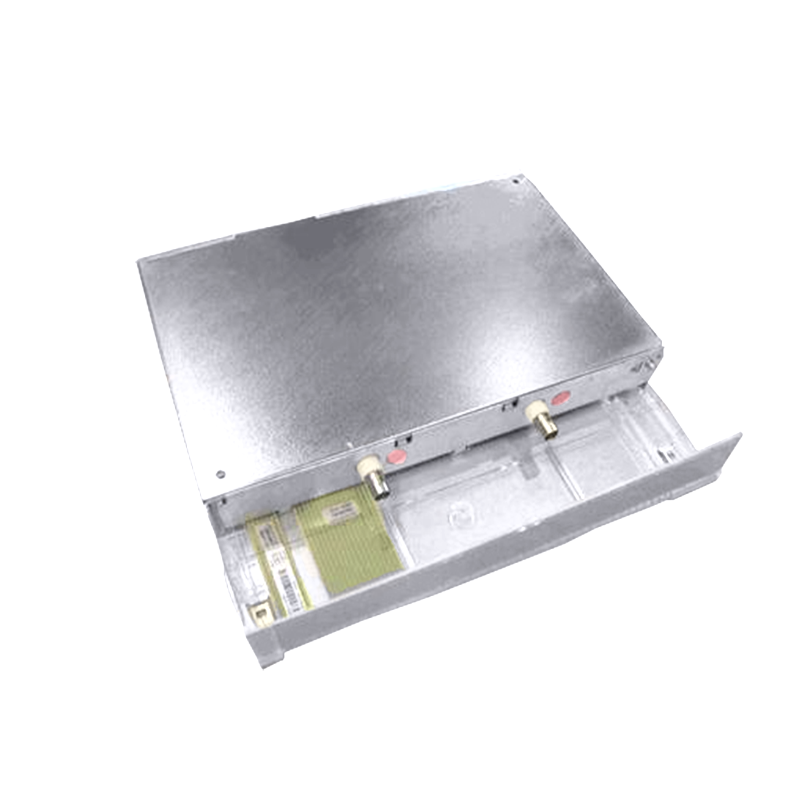

The ABB CP630 (1SAP530100R0001) is a robust industrial programmable control and interface module designed for use in advanced automation systems. It provides powerful logic processing, flexible I/O integration, and reliable communication capabilities for mid‑to‑large scale industrial applications. CP630 combines digital and analog signal handling with deterministic control, enabling real‑time automation tasks in processes such as machine control, process manufacturing, energy management, and building automation.

Equipped with both high‑speed processing capability and extensive input/output capacity, CP630 acts as a local control unit or a dedicated node in distributed control systems. Its rugged industrial design ensures dependable performance in environments with electrical noise, temperature fluctuations, vibration, and other demanding conditions. The module’s architecture supports modular expansion and simplifies system topology by consolidating logic, I/O, and communication in a single compact unit.

Brand and Product Series

-

Brand: ABB

-

Product Series: CP Control & Processing Modules Series

The CP series encompasses a range of programmable control modules that integrate logic processing, analog and digital I/O, and communication interfaces. These modules serve as the core processing units in industrial automation applications, offering flexible I/O configurations, clear diagnostics, and expandable architecture to fit varied control needs.

Product Introduction

The CP630 serves as a unified control and interface platform that acquires signals from field devices (sensors and actuators), executes programmed logic, and sends command signals to actuators or controllers. Its internal processing engine efficiently handles logic execution, timing functions, and communication operations, ensuring stable and predictable performance in real time.

CP630 features a blend of digital inputs, digital outputs, analog inputs, and analog outputs, supporting a wide range of industrial signal types without external converters. Standard communication ports allow connection to higher‑level supervisory systems, remote I/O modules, or networked controllers.

Built‑in diagnostics enable rapid status monitoring through LED indicators that show power presence, communication activity, I/O operations, and error conditions. These indicators assist technicians during installation, commissioning, and maintenance, helping reduce downtime and troubleshooting effort.

Typical Applications

Process Control and Automation

CP630 is suitable for continuous or batch processes in chemical plants, oil & gas, food processing, water treatment, and pharmaceutical industries, where precise control and monitoring of analog variables and digital logic are essential.

Machine Control and Production Automation

In manufacturing settings including discrete and hybrid production lines, CP630 supports machine startup/shutdown logic, safety interlocks, sequence control, and feedback loops for motion control.

Energy Monitoring and Power Management

Used in energy systems to gather input from power meters, transducers, and protective devices, CP630 can execute control algorithms for load balancing, fault detection, and energy reporting.

Building and Facility Automation

CP630 integrates with environmental sensors, HVAC systems, lighting controls, and access controls to provide centralized monitoring and automated responses for building systems.

Test, Measurement, and Laboratory Control

In engineering and industrial test facilities, CP630 provides reliable signal capture, conditional logic, and control for test benches where multiple analog and digital channels are involved.

Product Advantages

High Integration Density

CP630 supports a substantial number of digital and analog channels in one module, reducing the need for multiple interface devices and simplifying installation.

Reliable Real‑Time Processing

The module’s deterministic execution ensures consistent timing and control performance, critical for automated sequences and process regulation.

Flexible Expansion and Modularity

The design allows integration with additional I/O or communication modules to expand capabilities without redesigning system architecture.

Industrial‑Grade Durability

Engineered for harsh environments, CP630 offers resistance to temperature swings, electrical noise, and vibration, ensuring long operational life.

Comprehensive Diagnostics

Status LEDs provide immediate visual feedback on power, communication, I/O activity, and fault conditions, aiding quick field diagnosis.

Technical Specifications

| Specification | Details |

|---|---|

| Model | CP630 (1SAP530100R0001) |

| Module Type | Programmable Control & Interface Module |

| Digital Inputs | 48 inputs |

| Digital Outputs | 40 outputs |

| Analog Inputs | 32 channels |

| Analog Outputs | 16 channels |

| Communication Ports | RS‑485, Ethernet, Fieldbus (configurable) |

| Processor Type | Industrial logic controller core |

| Memory | 2 MB–8 MB application/data (configurable) |

| Execution Cycle | ~1 ms per 1000 instructions (typical) |

| Power Supply | 24 V DC |

| Power Consumption | 20 W |

| Operating Temperature | –20°C to +60°C |

| Storage Temperature | –40°C to +85°C |

| Isolation | Field-to‑logic isolation |

| Dimensions (H×W×D) | 180 mm × 120 mm × 85 mm |

| Weight (kg) | 2.30 kg |

| Mounting Method | Panel/DIN Rail |

| Status Indicators | Power, Comm, Error, I/O Activity LEDs |

Related Models — Same Series or Similar Function

| Model | Digital Inputs | Digital Outputs | Analog Inputs | Analog Outputs | Power (W) | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|

| CP601 | 32 | 24 | 16 | 8 | 15 W | 140 × 100 × 70 | 1.25 |

| CP602 | 36 | 28 | 18 | 9 | 16 W | 145 × 105 × 70 | 1.35 |

| CP605 | 48 | 32 | 24 | 12 | 20 W | 160 × 110 × 75 | 1.60 |

| CP620 | 56 | 40 | 32 | 16 | 22 W | 180 × 120 × 85 | 2.10 |

| CP650 | 64 | 48 | 40 | 20 | 28 W | 220 × 140 × 95 | 3.40 |

Other Popular Models — Same Brand

| Model | Function | Channels / Type | Power (W) | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|---|

| DI810 | Digital Input Module | 16 digital inputs | 2.0 | 90 × 120 × 25 | 0.32 |

| DO810 | Digital Output Module | 16 digital outputs | 2.0 | 90 × 120 × 25 | 0.33 |

| AI820 | Analog Input Module | 12 analog inputs | 3.0 | 90 × 120 × 40 | 0.50 |

| AO820 | Analog Output Module | 12 analog outputs | 3.0 | 90 × 120 × 40 | 0.50 |

| CI560 | Communication & I/O Interface | 32 DI / 16 AI | 15.0 | 180 × 240 × 85 | 3.10 |

Frequently Asked Questions (FAQ)

Q1: What is CP630 designed for?

A1: CP630 is a programmable control module used to collect field signals, execute control logic, and communicate with supervisory systems.

Q2: How many digital inputs are available on CP630?

A2: CP630 provides 48 digital input channels.

Q3: How many analog inputs does CP630 support?

A3: It supports 32 analog input channels.

Q4: What communication options does CP630 offer?

A4: CP630 includes RS‑485, Ethernet, and configurable Fieldbus interfaces for flexible networking.

Q5: What is the operating temperature range of CP630?

A5: The operating range is –20°C to +60°C.

Q6: What are the dimensions of CP630?

A6: The module measures 180 mm × 120 mm × 85 mm.

Q7: What is the weight of CP630?

A7: CP630 weighs approximately 2.30 kg.

Q8: Can CP630 be expanded with additional I/O modules?

A8: Yes, it can be integrated with additional modules for scalable automation solutions.

Q9: Does CP630 provide diagnostics?

A9: Yes, LEDs indicate power, communication, I/O activity, and error status.

Q10: Is CP630 suitable for industrial environments?

A10: Yes, CP630 is designed for harsh industrial environments with robust temperature and electrical noise tolerance.