ProductPRODUCT

Featured products

Contact Us

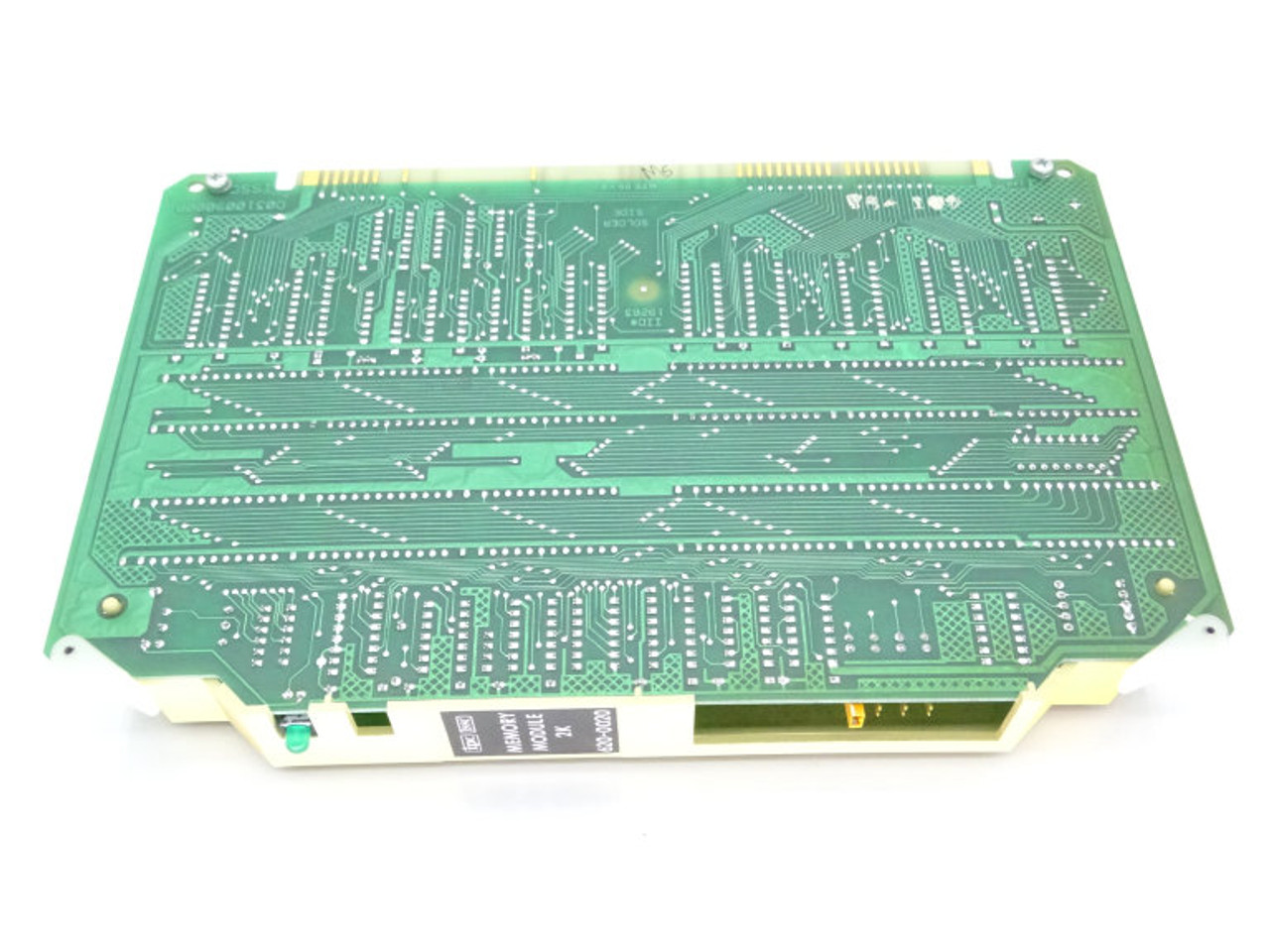

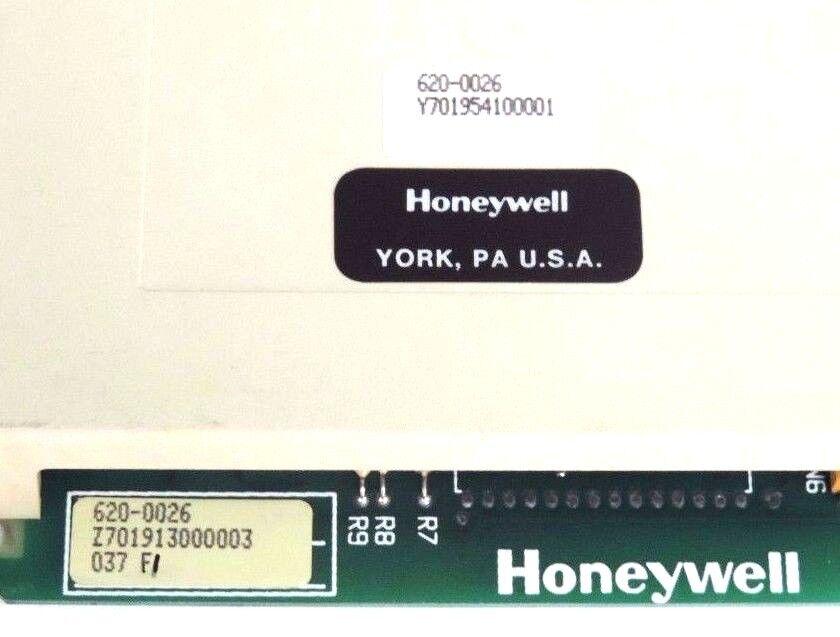

- Honeywell

- 620-0073C 6200073C

- ELPM Processor Module (C)

- USA

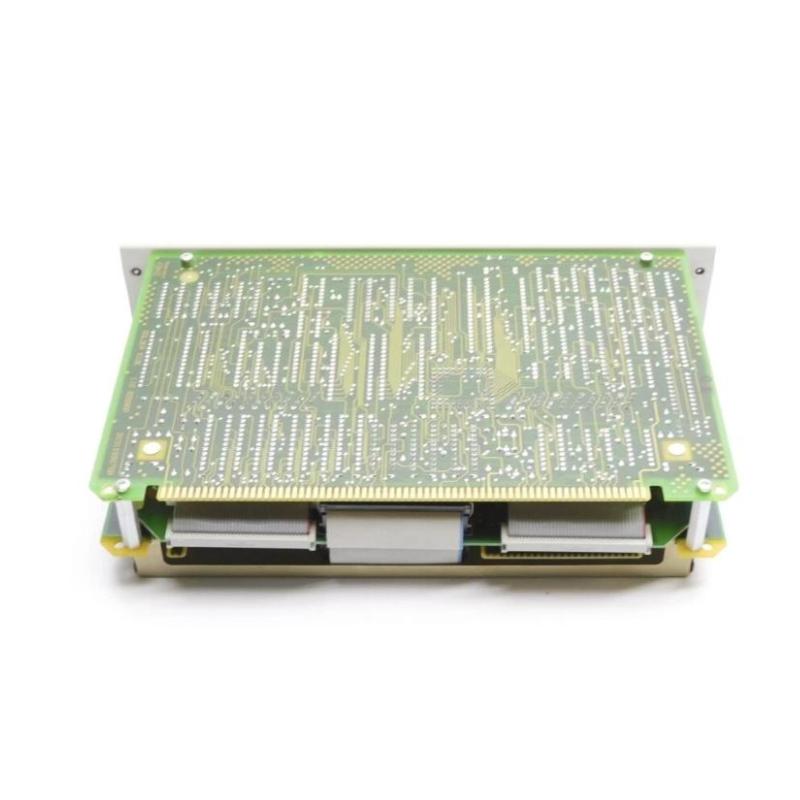

- 165 × 105 × 60 mm

- 0.68kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 34

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Product Specification and Overview — Model 620‑0073C

1. Product Introduction

The 620‑0073C is an industrial‑grade signal interface and control module engineered for precise data acquisition, signal conditioning, and communication in sophisticated automation systems. Designed to be a versatile bridge between sensors, actuators, and programmable controllers, the module converts diverse analog and digital inputs into clean, calibrated outputs suitable for process controllers, PLCs, and monitoring networks.

Unlike basic interface modules, the 620‑0073C incorporates enhanced filtering, configurable channel mapping, and extended isolation layers that minimize the influence of electrical noise, ground loops, and electromagnetic interference. This characteristic makes it particularly suitable for industrial environments where signal fidelity directly impacts system performance and safety.

The module’s architecture is centered around industrial reliability: robust internal circuitry, rugged enclosure design, and comprehensive protection mechanisms ensure consistent performance over long operational cycles. Standard DIN‑rail mounting allows quick installation within control racks, while accessible front‑panel indicators help technicians verify status and diagnose system conditions with minimal downtime.

Integrated communication support for both serial (RS‑485) and network (Ethernet) protocols expands flexibility, enabling the 620‑0073C to participate in distributed control architectures, remote monitoring applications, and complex automation networks.

2. Brand and Series Information

Brand: Industrial Automation Solutions

Series: Industrial Control & Sensor Series

The Industrial Control & Sensor Series is a portfolio of automation interface modules, input/output expansion units, communication gateways, and signal conditioning devices. Designed for reliability and long‑term performance, products in this series support a variety of industrial applications ranging from precision measurement to process automation and machine monitoring. These devices are engineered to integrate seamlessly with standard industrial control systems and to meet the environmental demands of factory, plant, and field operations.

3. Key Features & Advantages

The 620‑0073C module offers a range of technical and operational advantages:

-

Precision Signal Processing: Advanced filtering and conditioning ensure stable, accurate signal conversion with minimal drift.

-

Extended Isolation: Galvanic isolation between I/O and communication circuits reduces noise, enhances safety, and protects connected equipment.

-

Rugged Construction: Built to withstand vibration, shock, temperature extremes, and dust with a robust industrial enclosure.

-

Flexible Communication: Dual support for RS‑485 and Ethernet enables integration with both legacy and modern networked control systems.

-

High Channel Density: Supports multiple analog/digital channels in a compact footprint for efficient panel space usage.

-

DIN‑Rail Mounting: Standard industrial mounting simplifies installation and retrofit.

-

Configurable Parameters: Field‑programmable settings allow tuning of response thresholds, sampling rates, and communication parameters.

-

Low Maintenance: Factory calibration and industrial design reduce downtime and maintenance needs.

4. Typical Applications

The 620‑0073C is used in a wide range of industrial and manufacturing scenarios:

-

Process monitoring in chemical or energy plants

-

Automated production and assembly line control

-

Environmental and emissions monitoring systems

-

Machine condition sensing and predictive maintenance

-

Distributed sensor networks in large‑scale facilities

-

Industrial robotics feedback and synchronization

-

Energy management systems and utility control networks

5. Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 620‑0073C |

| Function | Multi‑channel interface & signal conditioner |

| Input Voltage | 24 V DC |

| Operating Temperature | -30°C to +80°C |

| Output Type | Analog (4–20 mA / 0–10 V) / Digital |

| Communication Interface | RS‑485 / Ethernet |

| Response Time | ≤ 1 ms |

| Protection Rating | IP65 |

| Isolation | Galvanic isolation between inputs/outputs/communication |

| Dimensions (L × W × H) | 165 × 105 × 60 mm |

| Weight | 0.68 kg |

| Mounting | DIN‑rail compatible |

6. Recommended Related Models — Same Series or Related Functionality

| Model | Function Description | Dimensions (mm) | Weight (kg) |

|---|---|---|---|

| 620‑0070 | Communication and data interface module | 150 × 95 × 50 | 0.57 |

| 620‑0071 | Sensor interface & signal conditioning | 155 × 100 × 55 | 0.60 |

| 620‑0072 | High‑precision interface & conditioning | 160 × 100 × 55 | 0.62 |

| 620‑0062 | Analog input monitoring module | 125 × 85 × 45 | 0.40 |

| 620‑0088 | High‑speed counter & logic interface | 130 × 90 × 50 | 0.45 |

7. Recommended Popular Models — Same Brand

| Model | Function Description | Dimensions (mm) | Weight (kg) |

|---|---|---|---|

| 530‑1101 | Multi‑axis motion controller | 140 × 100 × 55 | 0.60 |

| 530‑1125 | Precision process pressure sensor | 95 × 60 × 30 | 0.22 |

| 530‑1133 | Industrial signal conditioner | 120 × 80 × 40 | 0.36 |

| 530‑1150 | Programmable logic control unit | 150 × 110 × 60 | 0.75 |

| 530‑1177 | Network communication gateway | 130 × 85 × 45 | 0.48 |

8. Frequently Asked Questions (FAQ)

Q1: What types of environments is the 620‑0073C designed for?

A1: The module is designed for harsh industrial environments, including high vibration, temperature extremes, and electrical noise, with an IP65 enclosure for protection against dust and moisture.

Q2: What types of signals can the 620‑0073C process?

A2: It can process multiple analog (e.g., 4–20 mA, 0–10 V) and digital signals, converting them into conditioned outputs for controllers or monitoring systems.

Q3: What communication interfaces are available on this module?

A3: The module supports both RS‑485 and Ethernet communication standards, enabling integration with various types of industrial control networks.

Q4: How is the 620‑0073C powered?

A4: It operates on a 24 V DC industrial power supply, which is a standard input for most automation modules.

Q5: Does this unit require frequent calibration?

A5: The module is factory calibrated and engineered for long‑term stability, so frequent recalibration is not typically required.

Q6: Can the 620‑0073C be installed in a standard control panel?

A6: Yes, it is DIN‑rail compatible for easy installation in control cabinets and racks.

Q7: What is the typical response time for this module?

A7: Signal processing and conditioning occur within 1 ms or less, supporting near real‑time control and data acquisition.

Q8: Does this product provide electrical isolation?

A8: Yes, the module provides galvanic isolation between inputs, outputs, and communication circuits to protect connected equipment and improve signal quality.

Q9: Can multiple 620‑0073C units be used together?

A9: Yes, multiple units can be networked using RS‑485 or Ethernet, allowing scalable system expansion for larger automation setups.

Q10: What are the most common applications for this model?

A10: Common applications include automated production lines, machine condition monitoring, distributed sensor networks, environmental monitoring systems, and process control loops.