ProductPRODUCT

Featured products

Contact Us

- Bently Nevada

- 3500/53-02-00 133396-01

- Overspeed Detection I/O Module

- USA

- 241.3 mm × 24.4 mm × 99.1 mm

- 0.45kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 36

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| sales@plc-automations.com | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Bently Nevada 3500/53-02-00 (133396-01) – Detailed Product Overview

Product Introduction

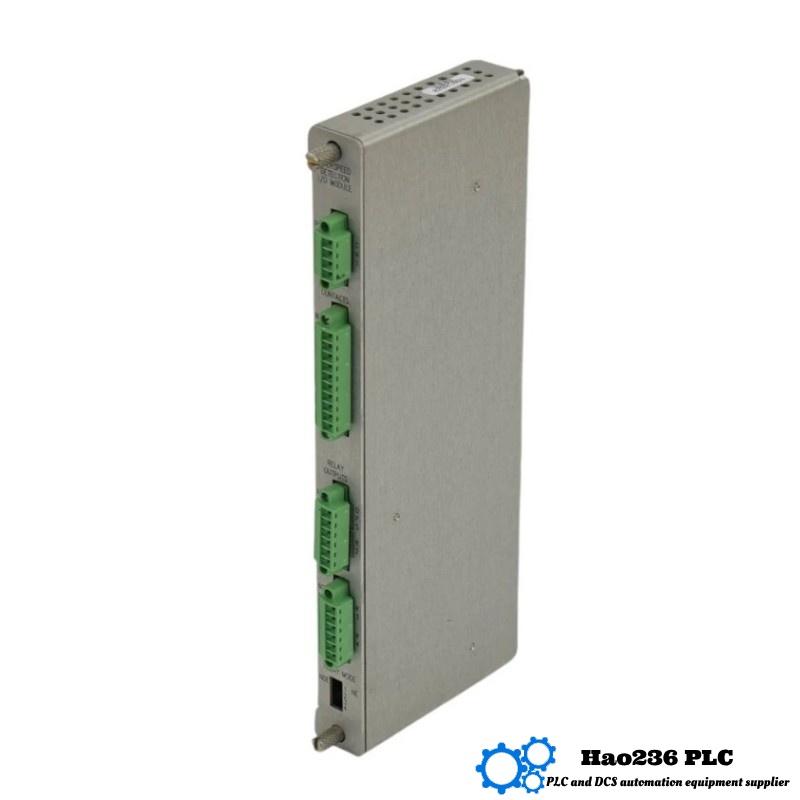

The Bently Nevada 3500/53-02-00 (P/N: 133396-01) is an Electronic Overspeed Detection I/O Module designed to detect and respond to overspeed conditions in critical rotating machinery. Belonging to the 3500 Series monitoring platform, this module is widely used in gas turbines, steam turbines, compressors, and generators to prevent catastrophic equipment failure caused by excessive rotational speed.

The module is installed in a 3500 rack and operates in conjunction with other modules to form a complete condition monitoring and protection system. It accepts speed input signals from proximity probes or magnetic pickups, providing both alarm relay outputs and proportional +4 to +20 mA current outputs for remote monitoring or control systems.

Technical Specifications

| Category | Specification |

|---|---|

| Model / Part Number | 3500/53-02-00 (133396-01) |

| Type | Overspeed Detection I/O Module |

| Series | 3500 Series / 53 Series |

| Input Signal Type | Proximity probes or magnetic pickups (Pulse signal) |

| Signal Input Range | +10.0 V to -24.0 V (internally clamped) |

| Input Impedance | Approx. 20 kΩ |

| Transducer Power Supply | -24 VDC, max 40 mA |

| Recorder Output | +4 to +20 mA, proportional to configured full-scale speed |

| Max Power Consumption | ~8.0 W |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Tolerance | Up to 95% RH, non-condensing |

| Environmental Sealing | Epoxy-sealed construction |

| Dimensions (H × W × D) | 241.3 mm × 24.4 mm × 99.1 mm |

| Weight | 0.45 kg |

| Shipping Weight | ~2.0 kg |

| Mounting Style | Installed in 3500 rack (rear slot per channel) |

| Compliance | Meets API 670, API 612 standards; supports redundant configurations |

Applications

-

Power Generation (Turbines): Overspeed protection for steam and gas turbines.

-

Oil & Gas: Speed monitoring for compressors and high-speed rotating equipment.

-

Chemical Plants: Pumps and mixers requiring precise speed control.

-

Offshore Platforms: Turbine engines and power units in harsh environments.

-

General Industrial Rotating Equipment: Any scenario where excessive RPM could damage machinery or pose safety risks.

Product Advantages

-

Fast Detection & Response: Optimized to rapidly identify overspeed conditions and trigger protective actions.

-

High Reliability: Supports redundant configurations with voting logic (2-of-2, 2-of-3) and error diagnostics.

-

Versatile Compatibility: Works with a wide range of probes including Bently Nevada’s proximity and magnetic pickups.

-

Rugged Design: Wide operating temperature range and sealed construction make it ideal for industrial environments.

-

User-Friendly Maintenance: Short-circuit protected outputs, front-panel diagnostics LEDs, and hot-swappable design.

-

Standards-Compliant: Designed to meet or exceed API standards for turbine safety and overspeed protection systems.

Brand and Series

-

Brand: Bently Nevada

-

Product Series: 3500 Series

-

Sub-series: 3500/53 (Electronic Overspeed Detection System)

Related Models in the Same Series (Recommended)

| Model | Input Type / Function | Temp Range | Size / Weight | Key Features |

|---|---|---|---|---|

| 3500/53-02-01 | Overspeed detection, proximity/magnetic pickup | -30°C to +65°C | ~0.5 kg | Similar to 02-00 with agency approvals |

| 3500/53 133388-01 | Full electronic overspeed detection | -30°C to +65°C | ~1.0 kg | Common version with standard settings |

| 3500/53-01 | Overspeed detection | -30°C to +65°C | ~0.5 kg | Basic model variant |

| 3500/53-03-00 | Advanced overspeed module | -30°C to +65°C | ~0.6 kg | Expanded input/output capability |

| 3500/53 Generic | Overspeed protection | -30°C to +65°C | ~0.5 kg | System-level redundancy and safety logic |

Popular Bently Nevada Models (Same Brand)

| Model | Function | Input/Output | Size / Weight | Application |

|---|---|---|---|---|

| 3500/40 135489-04 | Proximitor Signal I/O Module | Proximity probe input, 4–20 mA output | ~100×100×30 mm / ~0.5 kg | Vibration/position monitoring |

| 3500/42M 176449-02 | Combined seismic/prox monitor | Vibration, displacement inputs | ~170×110×50 mm / ~0.5 kg | Gearbox, rotor, seismic monitoring |

| 3500/33 149986-01 | 16-Channel Relay Output Module | Discrete relay outputs | Standard rack size / ~0.5 kg | Alarm/trip relay output |

| 3500/93 135785-01 | System Display Module | Displays RPM, alarms, channel status | ~150×120×30 mm / ~0.3 kg | Local visual status interface |

| 3500/15 125840-02 | Power Supply Module | AC or DC power input | Rack-sized / ~0.4 kg | Redundant power for system modules |

FAQs (Frequently Asked Questions)

Q1: Can this module support speeds above 100,000 RPM?

A: Yes, provided the frequency of pulses from the probes remains within the input range of the module and the associated sensor supports such RPM. You must ensure your system is calibrated with the correct events-per-revolution configuration.

Q2: What happens if the input voltage exceeds +10 V or goes below -24 V?

A: The module internally clamps voltages outside its operational range, protecting itself from signal spikes or transients.

Q3: Is it suitable for humid environments?

A: Yes. It tolerates up to 95% relative humidity (non-condensing). For environments where condensation is possible, proper environmental control or protective enclosures are recommended.

Q4: Will a short circuit on the recorder output damage the module?

A: No. The recorder output is protected against short circuits and will not affect module functionality if shorted.

Q5: How many modules are needed for a redundant system?

A: For a fully redundant system, 2-of-2 or 2-of-3 voting configurations are used, meaning at least two or preferably three modules.

Q6: What happens if the power supply fails?

A: The 3500 rack supports redundant power modules. If one fails, the system continues operating using the backup power supply without interruption.

Q7: Does this module provide local status indicators?

A: Yes. The front panel includes LEDs for OK, TX/RX (communications), Bypass, Test, and Alarm statuses for quick diagnostics.

Q8: What are the maintenance requirements?

A: Routine inspection of probe gaps, signal cable integrity, power supply status, and module diagnostics is recommended. The module is durable and requires minimal upkeep under normal conditions.

Q9: What should be checked before replacing this module?

A: Ensure the replacement module matches in part number, configuration, signal type, output channels, and certifications. Compatibility with rack and firmware is also critical.

Q10: Does it meet international safety or industrial standards?

A: Yes. It is designed to meet industrial standards such as API 670 and API 612. Certain versions may also have regional agency approvals.

Authenticity guarantee

All product specifications are original and authentic imported products. We have an annual sales volume of 300 million yuan, and we only produce original and authentic products. All customers who cooperate with us directly online can enjoy low discounts.

Free warehouse

We have a complete range of product models, 80% of conventional models are in stock, and we have established channels in Asia, Africa, North America, South America, and Europe, effectively shortening the order processing time and satisfying customers in a timely manner.

Technical Team

Fast delivery. Spot goods can be shipped on the same day, and the delivery time transaction is 20% faster than that of peers on average, with a delivery time accuracy rate of 99%.

Thoughtful after-sales service

24-hour after-sales service guarantee team, professional and standardized management service system.