ProductPRODUCT

Featured products

Contact Us

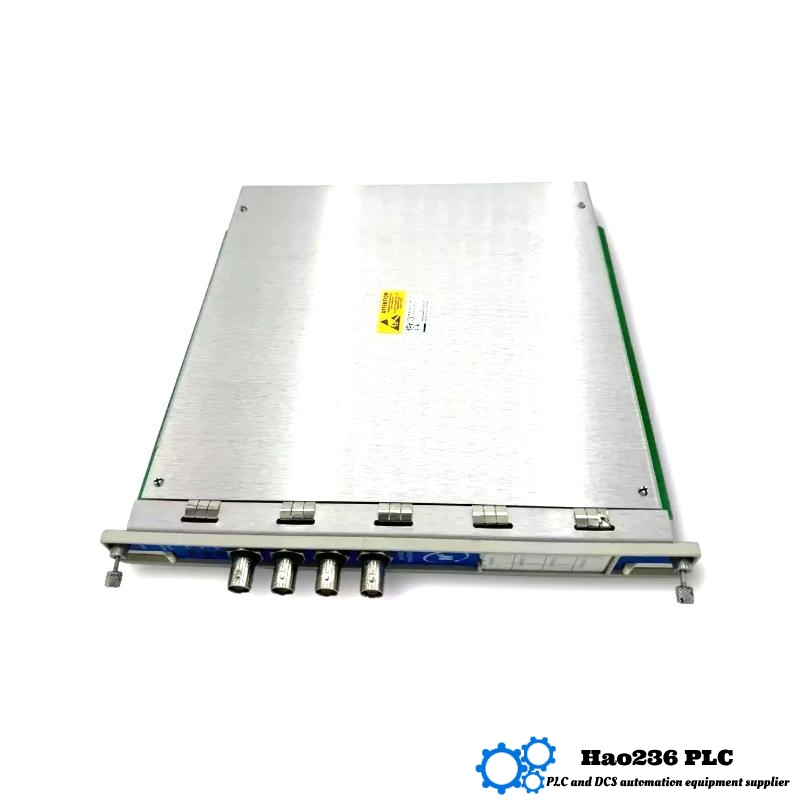

- Bently Nevada

- 3500/40 140734-01+125680-01

- Proximitor Monitor Module

- USA

- 483 x 533 x 179 mm

- 7.9kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 38

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| sales@plc-automations.com | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Bently Nevada 3500/40 140734-01 + 125680-01 – Product Overview

Product Introduction

The Bently Nevada 3500/40 140734-01 + 125680-01 is an advanced Machinery Protection and Condition Monitoring system from the 3500 Series by Bently Nevada. This system is designed to provide in-depth monitoring of critical machinery components, ensuring their health and performance are consistently optimized. It primarily focuses on the protection of rotating machinery, offering real-time diagnostics and alarming capabilities to prevent costly breakdowns.

The system is suitable for a variety of industries, including oil & gas, power generation, mining, and manufacturing, where equipment reliability is paramount. The system allows for predictive maintenance, reducing downtime and unplanned shutdowns while extending the lifespan of machinery.

Product Parameters

| Parameter | Description |

|---|---|

| Model | 3500/40 140734-01 + 125680-01 |

| Type | Machinery Protection and Condition Monitoring |

| Measuring Range | Vibration, Temperature, Speed, and Pressure Monitoring |

| Power Supply | 24 VDC (nominal) |

| Input Channels | 4 Analog Inputs, 4 Discrete Inputs |

| Communication Protocol | Modbus, Ethernet (Optional) |

| Dimensions | 483 x 533 x 179 mm (19 x 21 x 7 inches) |

| Weight | 7.9 kg (17.4 lbs) |

| Operating Temperature | -20°C to 60°C |

| Protection Class | IP65 (dust and water resistant) |

| Humidity Range | 5% to 95% (non-condensing) |

Product Applications

The 3500/40 140734-01 + 125680-01 system is designed for the protection and condition monitoring of critical rotating machinery, such as:

-

Turbines: Ensuring that turbines in power plants are continuously monitored for vibration, speed, and temperature.

-

Motors: Protecting electric motors in industrial settings, where overheating or unbalanced loads could lead to failure.

-

Compressors: Preventing failures in compressors that can disrupt production processes.

-

Pumps: Monitoring vibration and pressure parameters in pumps used in oil & gas or water treatment industries.

-

Conveyors: Ensuring the proper functioning of conveyor belts in manufacturing plants, reducing risk of unplanned shutdowns.

Product Advantages

-

Comprehensive Monitoring: The 3500/40 system provides multi-dimensional monitoring by measuring vibration, temperature, speed, and pressure. This ensures a complete view of the machinery’s condition.

-

Real-time Alerts: It allows operators to receive immediate alerts in case of abnormalities, providing ample time to take corrective actions before failures occur.

-

Predictive Maintenance: The system’s ability to collect and analyze data over time enables early detection of potential failures, reducing unplanned downtime.

-

User-friendly Interface: Designed with an intuitive interface, the system simplifies operations and makes it easier to identify issues that may require attention.

-

Reliable in Harsh Environments: The system’s rugged design ensures reliability even in harsh industrial environments, such as power plants and heavy manufacturing.

Brand & Series

-

Brand: Bently Nevada

-

Series: 3500 Series

-

Product Line: Machinery Protection and Condition Monitoring Systems

Recommended Models from the Same Series

| Model | Description | Weight (kg) | Dimensions (mm) |

|---|---|---|---|

| 3500/22 140734-01 + 125680-01 | Vibration and Temperature Monitoring | 7.2 | 480 x 530 x 175 |

| 3500/25 125792-01 + 149986-01 | Machinery Protection for Turbomachinery | 8.5 | 510 x 530 x 180 |

| 3500/32 140734-01 + 125680-02 | Vibration and Shock Detection | 7.8 | 490 x 520 x 175 |

| 3500/23 125720-01 + 125680-01 | Vibration Monitoring with Shock Detection | 6.8 | 505 x 505 x 180 |

| 3500/42 149992-01 + 125712-01 | Bearing and Gearbox Protection | 6.3 | 495 x 510 x 190 |

Recommended Models from Bently Nevada

| Model | Description | Weight (kg) | Dimensions (mm) |

|---|---|---|---|

| 3300/05 149987-01 | Vibration Monitoring for Rotating Equipment | 2.3 | 315 x 320 x 120 |

| 3500/61 125791-02 | Protection for Industrial Pumps | 7.0 | 510 x 510 x 180 |

| 3500/15 149986-01 | Generator and Motor Protection | 7.3 | 510 x 510 x 180 |

| 3500/21 133389-01 | Bearing & Gearbox Protection | 5.0 | 460 x 455 x 175 |

| 3300/06 149989-02 | Vibration Monitoring for Small Equipment | 3.0 | 300 x 305 x 100 |

Frequently Asked Questions (FAQ)

Q1: What does the 3500/40 system monitor?

A1: The 3500/40 system monitors critical parameters such as vibration, temperature, speed, and pressure to protect and maintain the health of rotating machinery.

Q2: Can the system detect faults in real-time?

A2: Yes, the 3500/40 provides real-time diagnostics, offering immediate alerts for any abnormal readings, allowing for quick corrective action.

Q3: Is this system scalable for large plants?

A3: Yes, the 3500/40 system can be expanded to monitor multiple pieces of equipment, making it suitable for large-scale industrial operations.

Q4: How does the 3500/40 help with predictive maintenance?

A4: By continuously collecting operational data, the system allows for trend analysis, helping identify potential problems before they cause machinery failures, enabling efficient predictive maintenance.

Q5: How does the system communicate with other equipment?

A5: The 3500/40 system supports communication protocols like Modbus and Ethernet, enabling seamless integration with other monitoring systems and equipment.

Q6: What industries benefit most from the 3500/40?

A6: The 3500/40 is ideal for industries such as oil and gas, power generation, mining, and manufacturing, where rotating machinery is critical to operations.

Q7: Is the 3500/40 system easy to install?

A7: Yes, the system is designed for easy installation and can be integrated into existing equipment protection setups with minimal disruption to operations.

Q8: What environmental conditions can the 3500/40 withstand?

A8: The 3500/40 is designed to function in harsh industrial environments with a wide operating temperature range and protection against dust and water (IP65).

Q9: Does the system provide historical data analysis?

A9: Yes, the system logs data over time, allowing operators to analyze trends and make informed decisions about maintenance and equipment reliability.

Q10: Can the 3500/40 be used in remote locations?

A10: Yes, the system can be accessed remotely via Ethernet, enabling operators to monitor machinery health from any location, improving flexibility.

Authenticity guarantee

All product specifications are original and authentic imported products. We have an annual sales volume of 300 million yuan, and we only produce original and authentic products. All customers who cooperate with us directly online can enjoy low discounts.

Free warehouse

We have a complete range of product models, 80% of conventional models are in stock, and we have established channels in Asia, Africa, North America, South America, and Europe, effectively shortening the order processing time and satisfying customers in a timely manner.

Technical Team

Fast delivery. Spot goods can be shipped on the same day, and the delivery time transaction is 20% faster than that of peers on average, with a delivery time accuracy rate of 99%.

Thoughtful after-sales service

24-hour after-sales service guarantee team, professional and standardized management service system.