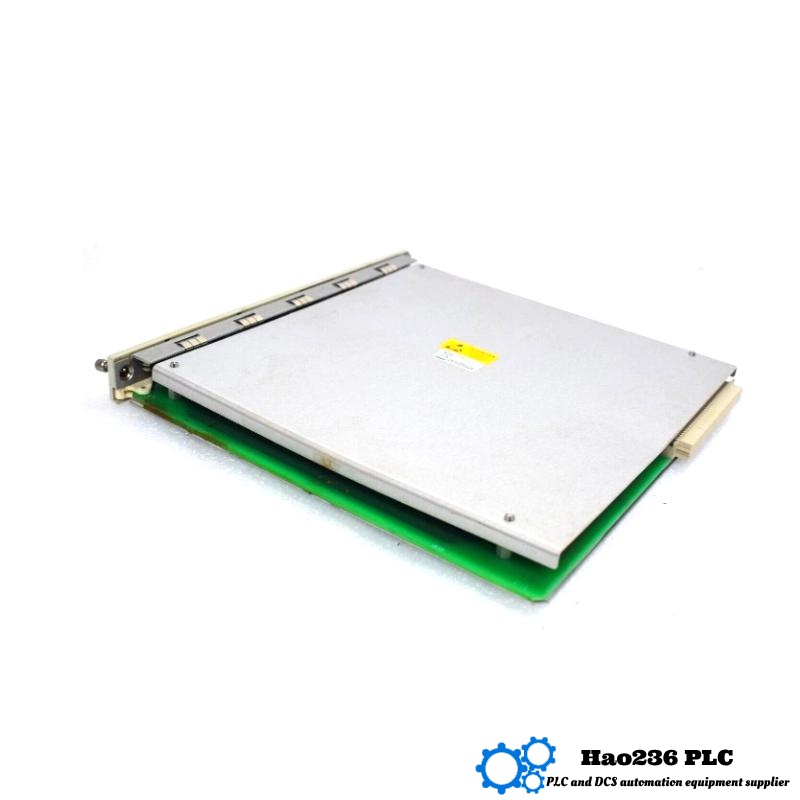

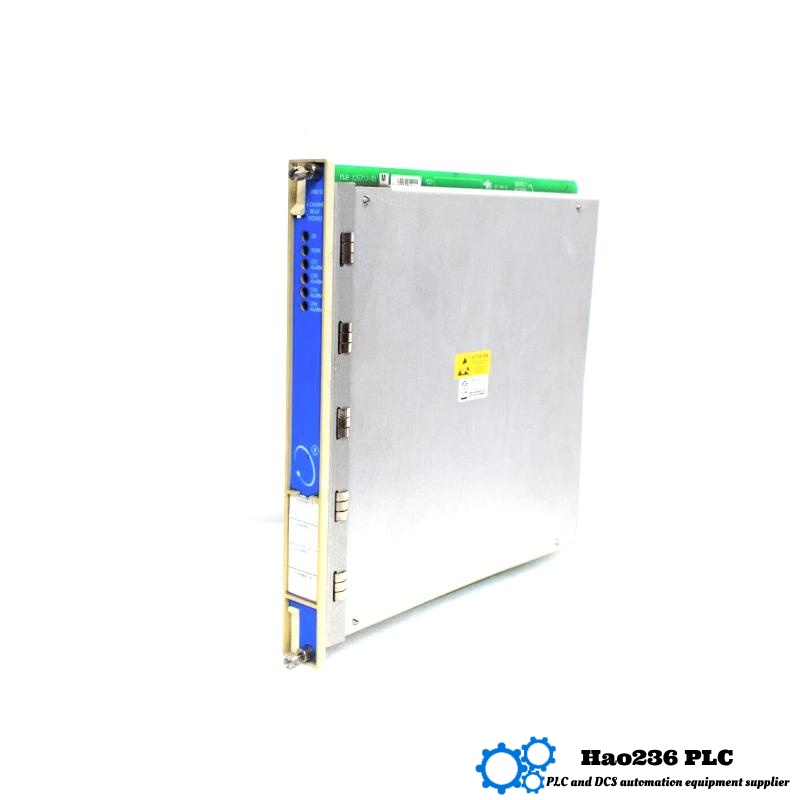

Product Overview: Bently Nevada 3500/32 149986-02 + 125720-01

Product Introduction:

The Bently Nevada 3500/32 149986-02 + 125720-01 system is an advanced vibration and condition monitoring solution designed to protect critical machinery by providing real-time diagnostic data. Part of the highly regarded 3500 Series, this monitoring system allows industries to continuously track the performance of rotating machinery like turbines, compressors, motors, and pumps, ensuring that any potential faults are detected early. The 3500/32 helps in avoiding unexpected downtime, extending equipment life, and lowering the overall maintenance costs.

The system is especially suitable for harsh industrial environments such as power plants, oil & gas operations, chemical processing plants, and manufacturing facilities where reliability and uptime are paramount. By continuously analyzing vibration, displacement, and position data, this product helps users identify critical failure points and make data-driven maintenance decisions.

Product Features:

-

Real-Time Monitoring: The system offers live monitoring of critical machinery, detecting early signs of imbalance, misalignment, and wear.

-

Advanced Diagnostics: 3500/32 provides detailed fault analysis and diagnostic features to predict potential failures, enabling proactive repairs before issues become catastrophic.

-

Scalable: It is easily scalable to monitor multiple pieces of machinery, making it a flexible solution for both small and large installations.

-

Rugged and Durable: With its IP65-rated enclosure, the 3500/32 is protected from dust, moisture, and extreme temperatures, making it ideal for industrial applications.

-

Comprehensive Communication Options: Supports Modbus, Profibus, and Ethernet for easy integration with existing control systems.

-

Ease of Installation and Maintenance: The system is designed for quick setup, minimal maintenance, and straightforward operation, reducing training requirements for operators.

-

Extended Equipment Life: By detecting potential issues early, the system helps extend the lifespan of critical machinery and minimizes expensive repairs or replacements.

Product Specifications:

| Specification |

Details |

| Model Number |

3500/32 149986-02 + 125720-01 |

| Type |

Vibration, Displacement, and Position Monitoring System |

| Dimensions (L x W x H) |

280 mm x 170 mm x 60 mm |

| Weight |

1.6 kg |

| Input Voltage |

24V DC |

| Measurement Range |

0 – 1000 Hz |

| Operating Temperature |

-20°C to 60°C |

| Environmental Protection |

NEMA 4X / IP65 |

| Mounting Type |

Panel or DIN Rail |

| Communication Protocols |

Modbus, Profibus, Ethernet |

Product Application:

The 3500/32 system is designed for a variety of industries and applications, including:

-

Power Generation: Continuous monitoring of turbines, compressors, and motors to ensure optimal performance in power plants.

-

Oil & Gas: Essential for monitoring rotating machinery such as pumps, compressors, and motors in oil rigs and refineries, where downtime is costly.

-

Chemical Processing: Tracks the condition of equipment such as reactors, pumps, and mixers to prevent failures in chemical production processes.

-

Manufacturing: Used in factories and plants to monitor motors, conveyors, and other equipment to prevent unplanned downtime and increase operational efficiency.

-

HVAC: Monitors large HVAC systems, ensuring consistent airflow and temperature control across industrial and commercial buildings.

Product Advantages:

-

Prevents Unplanned Downtime: The system’s real-time monitoring and diagnostics allow operators to identify and address issues before they cause failures.

-

Increased Equipment Longevity: By catching issues early, the 3500/32 extends the life of rotating machinery, reducing the need for costly repairs or replacements.

-

Improved Reliability: The system helps ensure continuous, trouble-free operation, which is crucial for industries that rely on high availability and performance.

-

Comprehensive Fault Diagnosis: With features like fault trending and advanced diagnostics, the 3500/32 helps operators predict potential issues before they become critical.

-

Flexibility and Scalability: This monitoring system can be easily scaled to accommodate more equipment, making it an excellent choice for both small and large installations.

-

User-Friendly: The system is designed for easy installation, setup, and operation, reducing the learning curve for operators and minimizing the need for frequent maintenance.

-

Durable Design: With an IP65 rating, it is built to withstand industrial conditions such as dust, moisture, and temperature extremes.

Brand:

-

Brand: Bently Nevada

-

Brand Overview: Bently Nevada is a trusted leader in machinery condition monitoring and vibration analysis. With decades of experience, their products help industries prevent machinery failures, extend equipment life, and increase operational efficiency. They offer a wide range of solutions tailored to power generation, oil & gas, manufacturing, and more.

Series:

Recommended Products in the Same Series or Related Models

| Model Number |

Key Features |

Weight (kg) |

Dimensions (L x W x H) |

| 3500/40 |

Vibration and displacement monitoring for turbines |

1.5 |

280 mm x 170 mm x 60 mm |

| 3500/45 |

High-speed rotating equipment protection |

1.7 |

280 mm x 170 mm x 60 mm |

| 3500/53 |

Machinery protection for compressors and pumps |

1.6 |

275 mm x 165 mm x 58 mm |

| 3500/22 |

Vibration monitoring for motors and fans |

1.4 |

265 mm x 160 mm x 58 mm |

| 3500/77 |

Protection system for turbines and motors |

1.5 |

270 mm x 165 mm x 60 mm |

Recommended Popular Models from the Same Brand

| Model Number |

Key Features |

Weight (kg) |

Dimensions (L x W x H) |

| 3500/42 |

Vibration and displacement sensor for rotating machinery |

1.3 |

250 mm x 160 mm x 55 mm |

| 3500/53M |

Machinery protection for compressors and turbines |

1.4 |

275 mm x 160 mm x 60 mm |

| 3500/35 |

Diagnostic system for gas turbines |

1.5 |

280 mm x 170 mm x 60 mm |

| 3500/22M |

Monitoring and diagnostics for motors and pumps |

1.4 |

260 mm x 155 mm x 55 mm |

| 3500/90 |

High-speed rotating equipment protection |

1.6 |

275 mm x 165 mm x 58 mm |