ProductPRODUCT

Featured products

Contact Us

- Bently Nevada

- 3500/22M 138607-01+146031-01

- Transient Data Interface (TDI) Module

- USA

- 241.3 x 24.4 x 241.8 mm

- 0.91kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 201

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

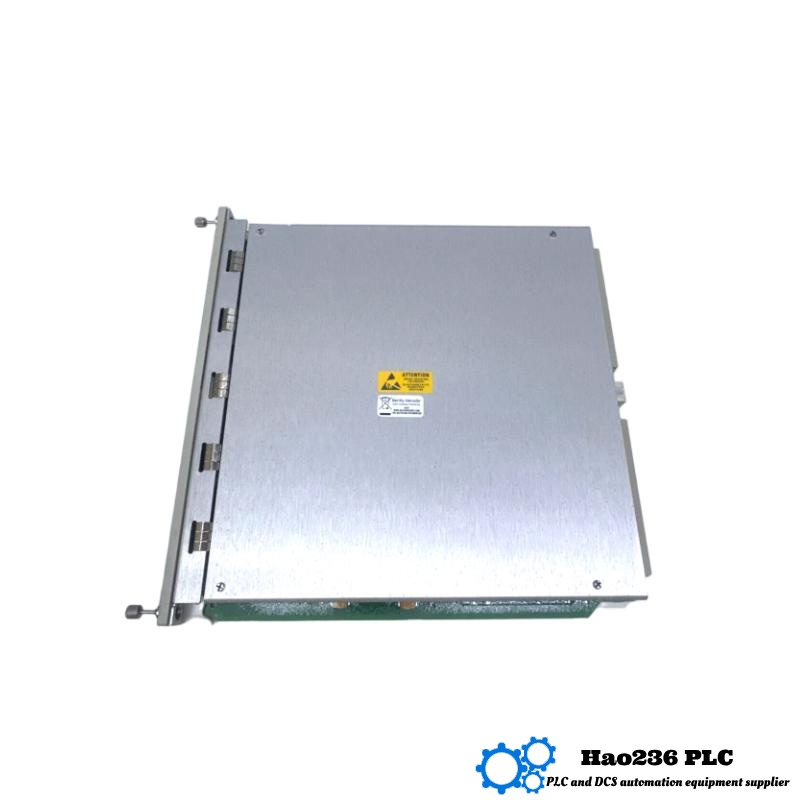

Bently Nevada 3500/22M 138607-01 + 146031-01 Transient Data Interface (TDI) Module

Product Introduction

The Bently Nevada 3500/22M 138607-01 + 146031-01 Transient Data Interface (TDI) Module is an advanced machinery monitoring component within the Bently Nevada 3500 Series. This high-performance module is designed to acquire transient data from vibration sensors, accelerometers, and other dynamic measurement devices to monitor the real-time health of machinery. It plays an essential role in detecting sudden changes or transient events like vibrations, shocks, and other critical events that could signal an impending machinery failure.

This module is used extensively in industrial environments, particularly in sectors like power generation, oil and gas, and manufacturing, where machinery reliability is critical. By continuously monitoring transient data, it allows for early detection of faults and optimizes maintenance strategies, reducing the risk of unplanned downtime. The 3500/22M 138607-01 + 146031-01 integrates seamlessly with other Bently Nevada 3500 Series modules, providing a comprehensive protection and monitoring solution for critical machinery.

Product Parameters

| Specification | Details |

|---|---|

| Model | 3500/22M 138607-01 + 146031-01 |

| Dimensions (L x W x H) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Input Channels | 8 |

| Output Channels | 2 |

| Data Acquisition | Real-time transient data |

| Input Voltage | 24V DC |

| Operating Temperature Range | -40°C to +70°C |

| Mounting Type | Rack-mount |

| Communication Protocol | Bently Nevada Communication Bus (BNC) |

| Power Consumption | 5W |

| Protection Class | IP20 |

Product Applications

The 3500/22M 138607-01 + 146031-01 Transient Data Interface Module is widely used for various machinery protection and condition monitoring applications:

-

Vibration and Shock Monitoring: This module helps monitor machinery performance by capturing transient data from sensors, detecting irregularities such as vibration imbalances, misalignments, or mechanical stress.

-

Predictive Maintenance: With real-time data acquisition and trend analysis, this module aids in predicting failures before they occur, optimizing maintenance schedules and minimizing equipment downtime.

-

Machinery Protection Systems: The 3500/22M provides critical insights into machine health, ensuring early warnings for conditions like bearing failure, shaft misalignment, and rotor imbalance.

-

Oil and Gas Industry: This module is used to monitor drilling equipment, pumps, and compressors, ensuring their safe operation in harsh conditions.

-

Power Generation: It helps monitor turbines, compressors, and other vital equipment in power plants, preventing unexpected outages and costly repairs.

-

Heavy Industry Manufacturing: In industries like steel and cement manufacturing, the module ensures that large machines, including crushers and mills, are continuously monitored for optimal performance.

Product Advantages

-

Real-Time Transient Data Acquisition: The 3500/22M 138607-01 + 146031-01 module provides real-time data collection, allowing users to detect transient events like vibration shocks, imbalance, and misalignment before they lead to catastrophic failures.

-

High Precision: With high-accuracy data acquisition, the module ensures precise monitoring of machinery health, providing reliable insights into its dynamic behavior.

-

Seamless Integration: This module is designed to integrate with other Bently Nevada 3500 Series components, creating a cohesive system for comprehensive machinery protection.

-

Predictive Maintenance Support: By capturing transient data, this module plays a vital role in predictive maintenance strategies, allowing for the anticipation of potential issues and reducing unplanned downtime.

-

Durable and Robust: Built to withstand extreme conditions, the module operates within a broad temperature range of -40°C to +70°C, making it suitable for harsh industrial environments.

-

Compact and Efficient: Despite its advanced capabilities, the 3500/22M module is compact, lightweight (0.91 kg), and easy to install into rack-mounted configurations, saving space in control cabinets.

Brand Information

Bently Nevada, is a global leader in machinery protection and condition monitoring technologies. With over 50 years of experience, Bently Nevada offers state-of-the-art solutions for monitoring the health of critical industrial equipment. Their products are trusted worldwide for enhancing equipment reliability, safety, and performance, particularly in industries like power generation, oil and gas, petrochemicals, and manufacturing.

Product Series

The 3500/22M is part of the Bently Nevada 3500 Series, a range of advanced machinery protection and monitoring systems. The 3500 series includes various modules that track key performance indicators like vibration, position, speed, and temperature, enabling operators to protect machinery, reduce operational risks, and optimize maintenance strategies.

Recommendations for Similar or Related Models

Here are five related models from the Bently Nevada 3500 Series or similar families:

| Model | Description | Parameters |

|---|---|---|

| 3500/22-01-03-00 | Transient Data Interface Module | Dimensions: 241.3 x 24.4 x 241.8 mm, Weight: 0.91 kg, 24V DC input |

| 3500/21-01-03-00 | Vibration Monitoring Module | Dimensions: 241.3 x 24.4 x 241.8 mm, Weight: 0.91 kg, 24V DC input |

| 3500/23-01-03-00 | Process Monitoring Interface Module | Dimensions: 241.3 x 24.4 x 241.8 mm, Weight: 0.91 kg, 24V DC input |

| 3500/33-01-01-00 | Machinery Condition Monitoring Module | Dimensions: 241.3 x 24.4 x 241.8 mm, Weight: 0.91 kg, 24V DC input |

| 3500/40-01-01-00 | Machinery Protection System | Dimensions: 241.3 x 24.4 x 241.8 mm, Weight: 0.91 kg, 24V DC input |

Recommendations for Top Bently Nevada Models

Here are five other popular Bently Nevada models widely used in industrial machinery monitoring:

| Model | Description | Parameters |

|---|---|---|

| 3500/44-01-01-00 | Dynamic Vibration Monitoring Module | Dimensions: 241.3 x 24.4 x 241.8 mm, Weight: 0.91 kg, 24V DC input |

| 3500/21-01-01-00 | Vibration Data Acquisition Module | Dimensions: 241.3 x 24.4 x 241.8 mm, Weight: 0.91 kg, 24V DC input |

| 3500/42-01-01-00 | Dynamic Pressure Monitoring Module | Dimensions: 241.3 x 24.4 x 241.8 mm, Weight: 0.91 kg, 24V DC input |

| 3500/34-01-01-00 | Bearing Wear Monitoring Module | Dimensions: 241.3 x 24.4 x 241.8 mm, Weight: 0.91 kg, 24V DC input |

| 3500/30-01-01-00 | Speed and Position Monitoring Module | Dimensions: 241.3 x 24.4 x 241.8 mm, Weight: 0.91 kg, 24V DC input |

FAQs

-

Q: What is the purpose of the 3500/22M 138607-01 + 146031-01 module?

A: The 3500/22M module is designed to collect transient data from machinery and sensors to monitor dynamic events like vibrations and shocks, aiding in predictive maintenance and early fault detection. -

Q: How many input channels does the 3500/22M 138607-01 + 146031-01 support?

A: The module supports 8 input channels, making it suitable for collecting data from multiple sensors simultaneously. -

Q: What is the power consumption of the 3500/22M 138607-01 + 146031-01?

A: The module consumes 5W of power during operation. -

Q: What is the weight of the 3500/22M?

A: The module weighs 0.91 kg, making it compact and easy to integrate into existing systems. -

Q: Can the 3500/22M 138607-01 + 146031-01 module be used in power plants?

A: Yes, the module is ideal for monitoring turbines, pumps, and other critical equipment in power generation plants. -

Q: How is data transmitted from the module?

A: The module uses the Bently Nevada Communication Bus (BNC) for data transfer to other system components. -

Q: What is the protection class of the module?

A: The module has an IP20 protection class, providing basic protection against dust and moisture. -

Q: Can the 3500/22M integrate with other Bently Nevada systems?

A: Yes, it integrates seamlessly with other products in the Bently Nevada 3500 Series. -

Q: What is the operating temperature range of the 3500/22M module?

A: The module operates in temperatures ranging from -40°C to +70°C. -

Q: What type of machinery is the 3500/22M used to monitor?

A: The module is used to monitor critical machinery like turbines, compressors, pumps, and motors in industries such as oil and gas, power generation, and manufacturing.