ProductPRODUCT

Featured products

Contact Us

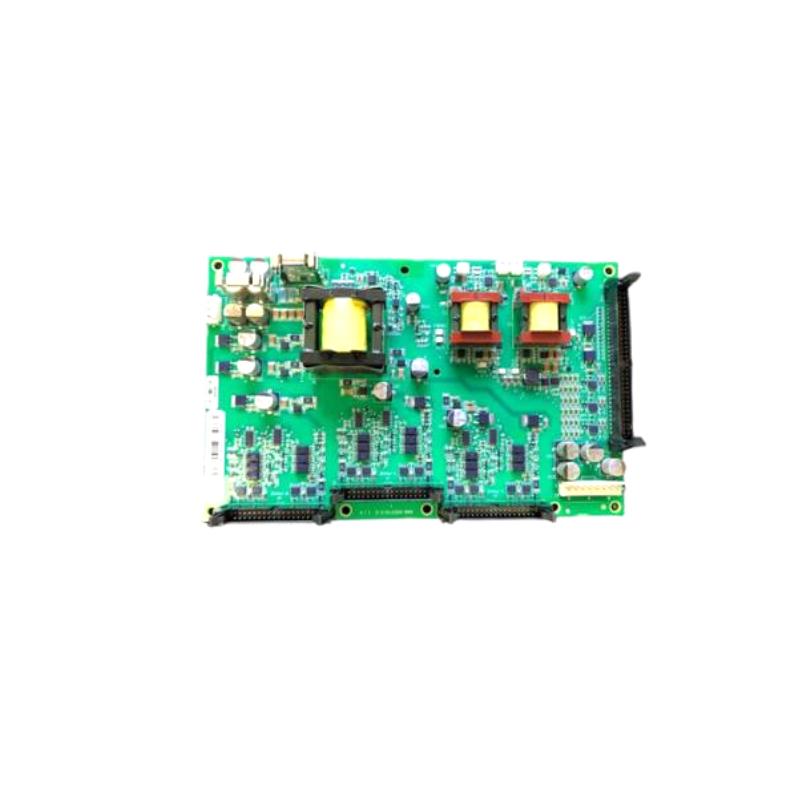

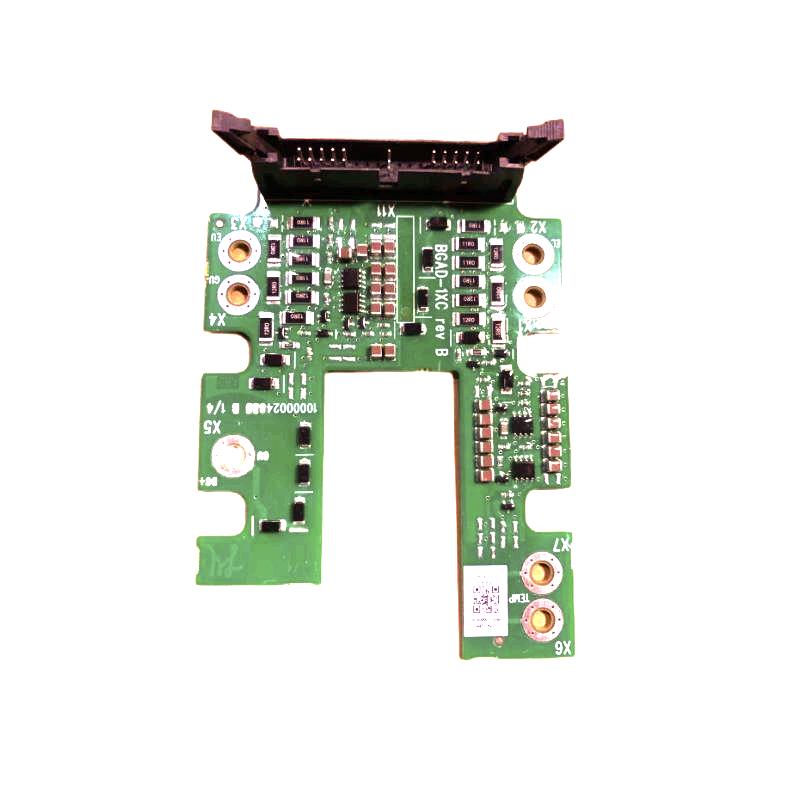

- OVATION

- 1C31110G02

- Westinghouse Emerson Digital Input Module

- USA

- 340 mm × 250 mm × 110 mm

- 5.1kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 45

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Product Technical Documentation — OVATION 1C31110G02

1. Product Overview

The OVATION 1C31110G02 is a high-end industrial automation controller engineered for advanced process control, real-time system monitoring, and scalable integration in complex distributed control systems (DCS). It is built for reliability and deterministic performance in environments where stable long-term operation is required, such as power generation, chemical processing, refining, water treatment, and large-scale manufacturing.

This model elevates the capabilities of standard automation modules by combining powerful multi-core processing, large I/O channel support, and flexible network communication interfaces. Its architecture is designed to support expanding system requirements throughout the lifecycle of industrial installations.

2. Product Introduction

The OVATION 1C31110G02 functions as a primary logic execution and field interface controller in automated systems. It collects sensor data, executes control algorithms, processes real-time feedback, and communicates outcomes to higher-level supervisory and historian systems. The unit is built with industrial-grade components and robust circuitry to ensure resistance to electrical noise, vibration, temperature fluctuation, and long operational hours.

Advanced internal diagnostics continuously evaluate system health, enabling predictive maintenance and reduced unscheduled downtimes. The modular structure facilitates future expandability including additional communication buses, I/O modules, and hardware redundancy options.

3. Applications

The OVATION 1C31110G02 is suitable for demanding industrial and infrastructure automation scenarios, including but not limited to:

-

Power Generation Systems

Used for turbine auxiliary control, feedwater regulation, emissions management logic, and centralized plant coordination. -

Chemical and Petrochemical Processes

Controls reaction loops, distillation columns, heat exchanges, interlocks, and safety shutdown systems. -

Oil & Gas Production and Refining

Manages compressor stations, pipeline logic, crude treatment units, fractionation control, and refinery intermediate controls. -

Water & Wastewater Treatment

Runs pumps, filtration stages, chemical dosing processes, and regional plant monitoring logic. -

Heavy Manufacturing Automation

Coordinates robotics, material handling, batch systems, assembly logic, and quality verification loops. -

Utility and Grid Automation

Handles substation logic, distributed generation support, load balancing, and telecommunications interfacing. -

Building and Facility Automation

Integrates HVAC control, energy metering, access logic, and safety systems into centralized automation schemes.

4. Product Advantages

The OVATION 1C31110G02 delivers the following advantages for industrial automation deployment:

-

High-Performance Processing:

Multi-core CPU enables complex control logic execution with minimal latency. -

Large I/O Capacity:

Supports extensive digital and analog channel counts to interface with a wide range of field devices. -

Flexible Protocol Support:

Compatible with Ethernet/IP, Modbus TCP, PROFIBUS, OPC UA, and other industrial standards. -

Robust Industrial Design:

Withstands harsh environments including wide temperature ranges, humidity extremes, vibration, and electrical interference. -

Scalable Architecture:

Modular design allows incremental system expansion without replacing core controller hardware. -

Comprehensive Diagnostics:

Integrated status indicators, error logs, and self-monitoring enhance serviceability and uptime. -

Maintenance-Oriented Engineering:

Field-replaceable modules reduce service time and simplify onsite maintenance. -

Long Lifecycle Support:

Designed for extended use in mission-critical applications with predictable service performance.

5. Brand and Product Series

-

Brand: OVATION

-

Series: OVATION High-Performance Industrial Controller Series

The OVATION High-Performance Industrial Controllers are crafted to meet demands of modern automation systems that require superior processing performance, extensive I/O-ranging, open communication interfaces, and long-term field reliability. Models in this series span from mid-range to high-capacity controllers tailored to diverse industrial sectors.

6. Technical Parameters — OVATION 1C31110G02

| Parameter | Specification |

|---|---|

| Model | OVATION 1C31110G02 |

| Controller Type | High-Performance Industrial Controller |

| Processor | Multi-Core Industrial CPU, 3.2 GHz |

| System Memory (RAM) | 16 GB ECC SDRAM |

| Internal Storage | 256 GB Industrial Flash |

| Digital I/O Channels | 160 Channels |

| Analog I/O Channels | 80 Channels |

| Network Interfaces | 4 × Gigabit Ethernet |

| Supported Protocols | Ethernet/IP, Modbus TCP, PROFIBUS, OPC UA |

| Control Cycle Time | ≤ 2 ms |

| Operating Temperature Range | –20 °C to +75 °C |

| Storage Temperature Range | –40 °C to +85 °C |

| Humidity Operating Range | 5% – 95% (non-condensing) |

| Power Input | 24 V DC |

| Power Consumption | Approx. 55 W |

| Dimensions (H × W × D) | 340 mm × 250 mm × 110 mm |

| Weight (kg) | 5.10 kg |

| Mounting Method | DIN Rail / Panel Mount |

7. Recommended Models from the Same Series

Below are five related or compatible models within the OVATION High-Performance Industrial Controller Series. These alternatives vary in processing performance, I/O capacity, and communication features for different application scales:

| Model | Processor | I/O Configuration | Network Support | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|---|

| OVATION 1C31099H01 | Multi-Core 3.0 GHz | 128 DI / 64 AI | 4 × Ethernet, OPC UA | 300 × 220 × 100 | 4.20 |

| OVATION 1C31105G03 | Hexa-Core 2.8 GHz | 112 DI / 56 AI | Ethernet/IP, Modbus | 280 × 200 × 95 | 3.65 |

| OVATION 1C31108G02 | Multi-Core 2.6 GHz | 104 DI / 52 AI | Ethernet/IP, PROFIBUS | 270 × 190 × 90 | 3.55 |

| OVATION 1C31088G09 | Hexa-Core 2.5 GHz | 64 DI / 32 AI | Dual Ethernet/IP | 260 × 185 × 90 | 3.50 |

| OVATION 1C31075G11 | Quad-Core 2.2 GHz | 48 DI / 24 AI | Ethernet/IP | 250 × 175 × 90 | 3.25 |

8. Popular Models from the Same Brand

Below are five widely adopted controllers from the broader OVATION automation product portfolio. These models are recognized for robust performance, versatile use cases, and integration across diverse industrial systems:

| Model | Primary Function | Key Feature | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|

| OVATION 2C40018H04 | Redundant Enterprise Controller | Dual CPU Redundancy | 250 × 190 × 95 | 3.30 |

| OVATION 2C40015H03 | Safety Control Module | Functional Safety Support | 240 × 185 × 95 | 3.10 |

| OVATION 2C40012H02 | Network Control Unit | Multi-Protocol Support | 225 × 175 × 90 | 2.60 |

| OVATION 2C40010H01 | High-Speed Logic Controller | Real-Time Logic Execution | 230 × 180 × 90 | 2.80 |

| OVATION 2C40022H06 | Integration Gateway Controller | Network Bridging and Data Conversion | 220 × 170 × 85 | 2.50 |

9. FAQ — OVATION 1C31110G02

Q1: What environments is the OVATION 1C31110G02 designed for?

A1: It is designed for demanding industrial environments such as power plants, chemical processing facilities, and large manufacturing operations where reliability and performance are essential.

Q2: How many I/O channels does this model support?

A2: This controller supports 160 digital and 80 analog channels, accommodating extensive field device interfacing.

Q3: What communication protocols are supported?

A3: Supported protocols include Ethernet/IP, Modbus TCP, PROFIBUS, and OPC UA for wide interoperability.

Q4: Can this controller run continuously without interruption?

A4: Yes, it is engineered for continuous 24/7 operation with robust industrial components and integrated diagnostics.

Q5: What power supply is required?

A5: The unit requires a regulated 24 V DC industrial power supply.

Q6: How does the controller assist with maintenance?

A6: Built-in diagnostics, status LEDs, and internal logs help identify issues early and support maintenance planning.

Q7: Can the controller be expanded after installation?

A7: Yes, its modular design allows additional I/O and communication modules to be added to meet evolving system needs.

Q8: What temperature range can it operate in?

A8: It operates reliably between –20 °C and +75 °C, suitable for many industrial environments.

Q9: Is this controller compatible with legacy automation equipment?

A9: Yes, flexible protocol support allows integration with legacy systems that use standard industrial communication interfaces.

Q10: What mounting options are available?

A10: The controller can be mounted on a DIN rail or panel mount, providing flexibility for installation in electrical enclosures and control cabinets.