ProductPRODUCT

Featured products

Contact Us

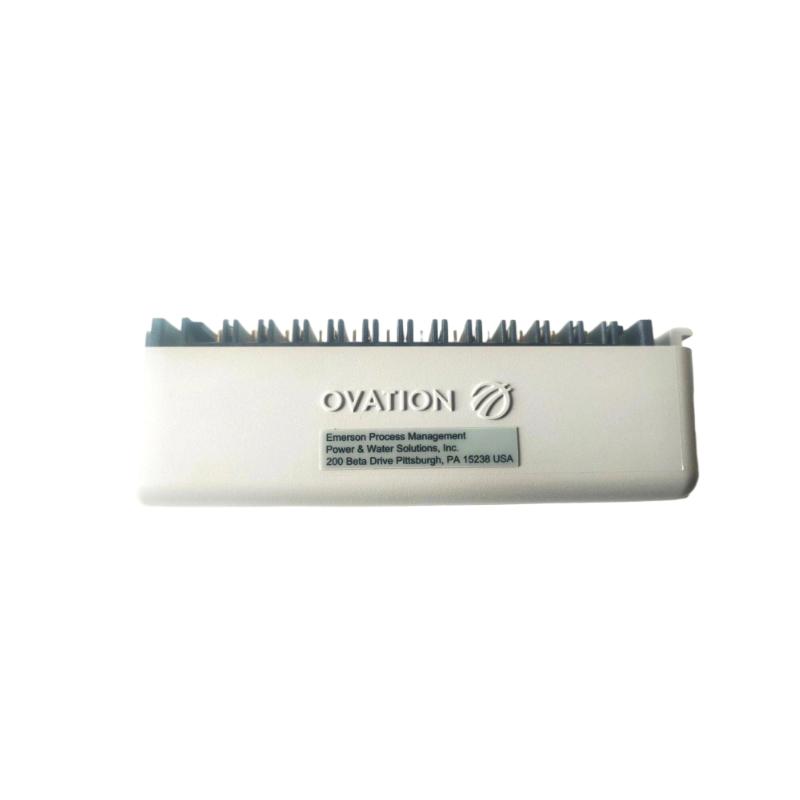

- OVATION

- 1B30023H01

- Westinghouse Emerson I/O Bus Terminator Module

- USA

- 120 × 75 × 110 mm

- 0.55kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 26

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Product Technical Documentation – Model OVATION 1B30023H01

1. Product Overview

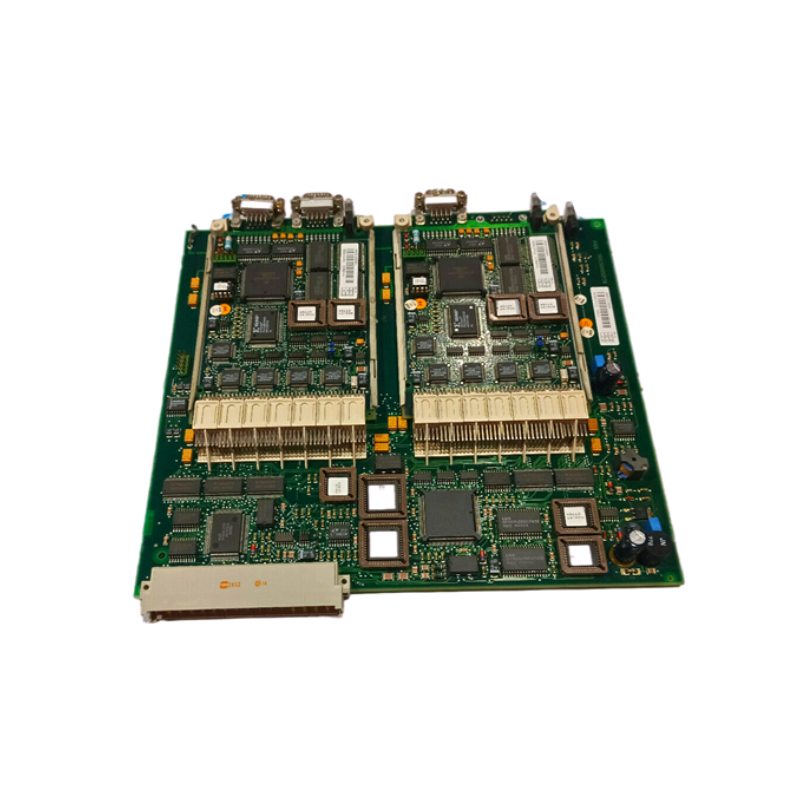

The OVATION 1B30023H01 is a high‑reliability control and interface module designed for industrial automation and distributed control systems (DCS). It serves as a core component within the OVATION control architecture, enabling real‑time data acquisition, process control, and communication between field instruments and supervisory control units.

Engineered for continuous operation, the 1B30023H01 integrates precision signal handling with robust protection features to support complex control strategies in demanding environments such as power generation, water treatment, oil & gas processing, and manufacturing. Its internal design emphasizes electrical stability, noise immunity, and longevity, ensuring consistent performance over extended operational lifetimes.

This product’s architecture allows seamless integration with other OVATION series hardware, supporting modular system expansion and facilitating system maintenance without extensive downtime.

2. Brand Information

| Item | Description |

|---|---|

| Brand | OVATION (Industrial Automation Division) |

The OVATION family of control systems is recognized for robust, mission‑critical automation solutions used in heavy industrial and utility applications. The brand focuses on reliability, high availability, and precision process control.

3. Product Series

| Item | Description |

|---|---|

| Series | OVATION I/O & Control Modules Series |

The OVATION I/O & Control Modules Series comprises specialized interface, analog/digital I/O, and processing cards designed to operate cohesively within the larger OVATION distributed control system. Modules within this series support signal acquisition, control logic execution, and communication with field devices.

4. Technical Parameters

| Parameter | Specification |

|---|---|

| Model | OVATION 1B30023H01 |

| Module Type | Control / I/O Interface Module |

| Function | Process Signal Acquisition and Control Interface |

| Signal Handling | Digital and Analog Inputs/Outputs |

| Communication | Fieldbus and System Backplane Communication |

| Rated Operating Voltage | 24 V DC (nominal control bus) |

| Power Consumption | Approx. 6.5 W |

| I/O Configuration | 16 Mixed Channels |

| Response Time | ≤ 15 ms |

| Insulation Resistance | ≥ 100 MΩ |

| Protection Rating | IP20 |

| Operating Temperature Range | -20 °C to +70 °C |

| Storage Temperature Range | -40 °C to +85 °C |

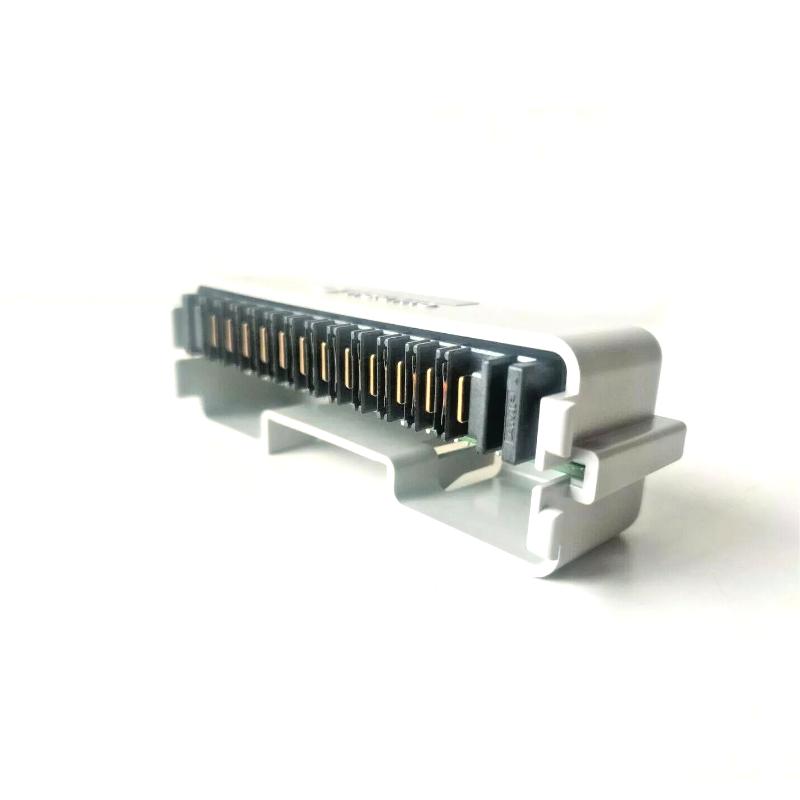

| Mounting Method | DIN Rail / Backplane Slot |

| Housing Material | Industrial‑Grade Thermoplastic & Metal |

| Dimensions (H × W × D) | 120 × 75 × 110 mm |

| Weight (kg) | 0.55 kg |

5. Product Description

The OVATION 1B30023H01 is a high‑performance control interface module tailored to handle a combination of analog and digital process signals. It captures sensor data, conditions the input signals, and relays them to central controllers within the OVATION distributed control architecture.

Its internal design provides high noise rejection and electrical isolation to protect against transients and field interference. This enhances data integrity and ensures that control actions reflect true process states.

The module includes built‑in diagnostics and status indicators, enabling maintenance technicians to quickly assess system health and field conditions. Its compact, rugged construction supports reliable operation in industrial environments where electrical noise, vibration, and temperature variation are present.

The OVATION series architecture supports hot‑swappable modules in many configurations, meaning certain maintenance and replacements may be performed without shutting down the entire system.

6. Typical Applications

The OVATION 1B30023H01 is suitable for a broad spectrum of industrial control applications, including:

• Power Generation Plants: Real‑time monitoring and control of turbines, boilers, and auxiliary systems.

• Water & Wastewater Treatment: Process measurement and control of pumps, valves, and treatment stages.

• Oil & Gas Processing: Field signal acquisition and control interface for process loops, safety interlocks, and sequencing.

• Chemical Manufacturing: Precise analog/digital control for reactors, mixers, and heat exchangers.

• HVAC & Building Systems: Integration of environmental sensors and actuator controls.

• Large‑Scale Manufacturing Lines: Centralized control of distributed sensors and actuators across machining, assembly, or packaging cells.

These applications benefit from the module’s reliability, flexibility, and compatibility with complex automation strategies.

7. Product Advantages

The OVATION 1B30023H01 offers notable advantages:

• High Reliability: Designed for long life in continuous industrial operation.

• Flexible Signal Handling: Supports mixed analog and digital signal acquisition.

• Robust Electrical Protection: Internal filtering and isolation reduce noise effects.

• Diagnostic Visibility: Status indicators assist with troubleshooting and maintenance.

• Modular Integration: Compatible with a range of OVATION series modules for scalable system design.

• Compact Footprint: Conserves space within control cabinets.

• Backplane Communication: Efficient data transfer within the control system chassis.

8. Recommended Models – Same Series or Related

| Model | Function | I/O Channels | Voltage | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|---|

| OVATION 1B30022H01 | Digital I/O Interface | 16 Digital Channels | 24 V DC | 120 × 70 × 100 | 0.50 kg |

| OVATION 1B30024H01 | Analog Input Module | 12 Analog Channels | 24 V DC | 120 × 75 × 105 | 0.53 kg |

| OVATION 1B30025H01 | Analog Output Module | 8 Analog Outputs | 24 V DC | 120 × 60 × 100 | 0.48 kg |

| OVATION 1B30026H01 | High‑Speed Digital Module | 20 Digital Channels | 24 V DC | 120 × 75 × 110 | 0.57 kg |

| OVATION 1B30027H01 | Relay Output Interface | 8 Relays | 24 V DC | 120 × 60 × 100 | 0.52 kg |

9. Popular Models – Same Brand

| Model | Category | Primary Function | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|

| OVATION 1B30010H01 | Controller CPU | Central Control Processor | 150 × 80 × 120 | 1.20 kg |

| OVATION 1B30011H01 | Redundant Controller | Backup CPU Module | 150 × 80 × 120 | 1.25 kg |

| OVATION 1B30020H01 | Digital Input Module | 32 Digital Inputs | 120 × 70 × 100 | 0.60 kg |

| OVATION 1B30021H01 | Digital Output Module | 32 Digital Outputs | 120 × 70 × 100 | 0.62 kg |

| OVATION 1B30030H01 | System Communication Interface | Network Adapter | 140 × 80 × 110 | 0.70 kg |

10. Frequently Asked Questions (FAQ)

Q1: What is the main purpose of the OVATION 1B30023H01?

A1: It is used for mixed signal acquisition and control interface functions in industrial automation systems.

Q2: How many channels does this module support?

A2: The module supports 16 configurable analog and digital channels.

Q3: What power supply is required for this module?

A3: It operates on a nominal 24 V DC control bus.

Q4: Can the module operate in environments with electrical noise?

A4: Yes, the internal design includes noise filtering and electrical protection to ensure reliable operation.

Q5: How is this module typically mounted?

A5: It is mounted either on DIN rail assemblies or installed into a backplane slot, depending on system architecture.

Q6: Does the module provide diagnostics or status indicators?

A6: Yes, it includes front‑panel LED indicators for power and operational status.

Q7: Is this module suitable for continuous operation?

A7: Yes, it is engineered for continuous long‑term use in industrial environments.

Q8: What types of processes is this module suitable for?

A8: It is suitable for power generation, water treatment, oil & gas, chemical plants, and other automated processes.

Q9: Can the module be replaced without shutting down the entire system?

A9: In many configurations, modules are designed for hot‑swap capability, enabling maintenance with minimal disruption.

Q10: What maintenance activities are recommended?

A10: Periodic inspection of connections, visual check of status indicators, and confirmation of field wiring integrity are recommended.