ProductPRODUCT

Featured products

Contact Us

- Bently Nevada

- 3500/65 172115-01

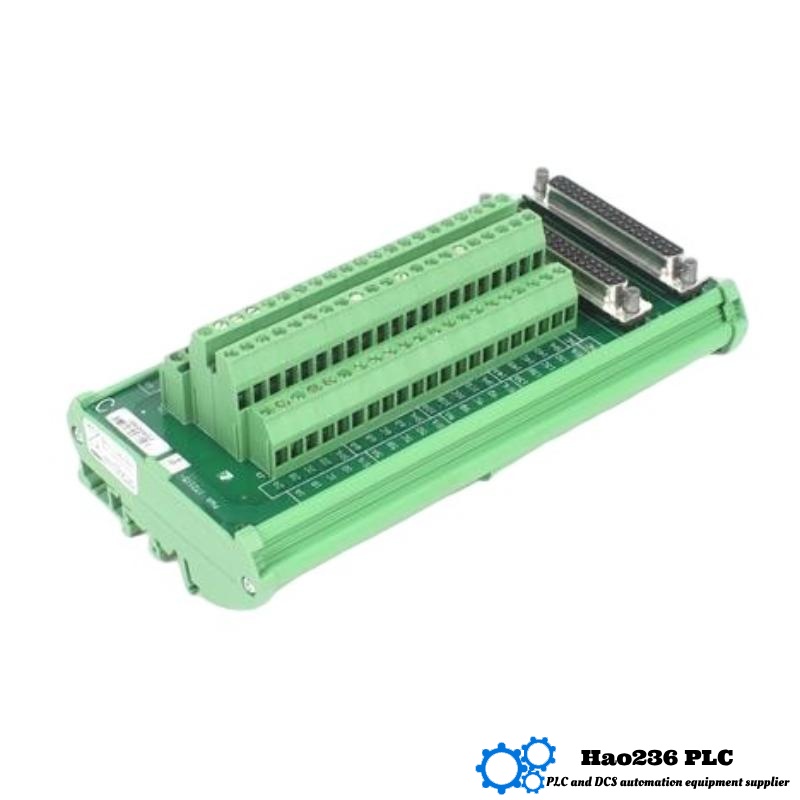

- External Termination Block Module 16-Channel Temperature Monitor

- USA

- 120 mm x 220 mm x 180 mm

- 2.2kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 63

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| sales@plc-automations.com | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Bentley Nevada 3500/65 172115-01 Product Overview

Product Introduction:

The Bentley Nevada 3500/65 172115-01 is a state-of-the-art machinery monitoring and protection system. It is designed to help industrial facilities optimize their operations by providing real-time monitoring of machine health, including vibration, temperature, pressure, and other critical parameters. The 3500/65 module is part of the renowned Bentley Nevada 3500 Series, which is known for its precision and reliability in critical industrial applications.

The 3500/65 system is specifically engineered for the protection and monitoring of rotating machinery. It collects data from various sensors and provides early warning of potential problems, thus allowing operators to take proactive actions. This helps reduce the risk of unexpected breakdowns, which can lead to costly downtime and repair work. The product is particularly valuable in industries where machinery reliability is essential to maintaining smooth operations and safety.

Product Applications:

The Bentley Nevada 3500/65 172115-01 can be used in a wide variety of industries that rely on rotating machinery. Key applications include:

-

Power Generation: Monitoring turbines, generators, and auxiliary equipment to ensure stable and continuous power production.

-

Oil & Gas: Protecting critical machinery like compressors, pumps, motors, and engines from premature failure.

-

Mining: Protecting and monitoring large-scale equipment such as crushers, mills, and conveyor systems.

-

Chemical Processing: Ensuring operational safety and performance by monitoring agitators, pumps, and other critical machinery.

-

Water Treatment: Used in the monitoring of pumps, blowers, and other critical machinery to ensure efficient operations and minimize downtime.

Product Advantages:

-

Comprehensive Monitoring: The 3500/65 module is capable of monitoring a variety of machine parameters, including vibration, pressure, and temperature, ensuring a complete view of machine health.

-

Real-Time Alerts: Provides real-time monitoring and early warning signals when any of the monitored parameters move out of the acceptable range, allowing operators to take corrective actions.

-

Ease of Integration: The system can easily be integrated into existing monitoring setups, allowing for centralized control and data analysis.

-

Long-Term Durability: The 3500/65 is built to withstand harsh industrial environments, with rugged construction and robust protection features.

-

Reduced Maintenance Costs: By detecting issues early, the system reduces the need for costly unplanned maintenance and downtime.

-

Scalability: Whether you’re operating a small facility or a large-scale plant, the Bentley Nevada 3500/65 can be scaled to meet the needs of different operations.

Brand and Series:

-

Brand: Bentley Nevada

-

Series: 3500 Series

-

Model: 3500/65 172115-01

Product Specifications:

| Parameter | Value |

|---|---|

| Model | 3500/65 172115-01 |

| Type | Machinery Protection System |

| Input Parameters | Vibration, Pressure, Temperature, Velocity |

| Measurement Range | 0-500 Hz (Vibration), 0-200 bar (Pressure) |

| Accuracy | ±1% of reading or ±0.05% full scale |

| Supply Voltage | 24 V DC (nominal) |

| Output | 4-20 mA Analog Output, Modbus RS-485 |

| Dimensions (H x W x D) | 120 mm x 220 mm x 180 mm |

| Weight | 2.2 kg |

| Operating Temperature | -40°C to +70°C |

| Protection Class | IP65 |

| Mounting Type | DIN Rail Mounting |

| Communication Protocol | Modbus RTU, 4-20mA Output |

Recommended Products from the Same Series or Related Models

| Model | Parameter |

|---|---|

| 3500/22 172115-02 | Vibration and temperature monitoring system |

| 3500/40 172115-03 | Advanced machinery protection and condition monitoring |

| 3500/62 172115-04 | Vibration and displacement monitoring system |

| 3500/45 172115-05 | Pressure and temperature monitoring for rotating machinery |

| 3500/91 172115-06 | Comprehensive machine condition monitoring |

Recommended Popular Models from Bentley Nevada

| Model | Parameter |

|---|---|

| 3500/25 172115-01 | Control system for vibration and temperature monitoring |

| 3500/33 172115-02 | Real-time vibration and fault detection system |

| 3500/60 172115-03 | Motor protection and performance monitoring |

| 3500/91 172115-04 | Advanced machinery protection and monitoring system |

| 3500/20 172115-05 | Vibration and displacement monitoring for rotating equipment |

FAQ:

Q1: What type of machines can the Bentley Nevada 3500/65 monitor?

A1: The Bentley Nevada 3500/65 is designed to monitor a wide range of rotating machinery, including turbines, pumps, motors, compressors, and other critical equipment in various industrial applications.

Q2: What parameters does the 3500/65 measure?

A2: The 3500/65 measures vibration, temperature, pressure, and velocity, providing a comprehensive overview of machine health.

Q3: How does the system detect machine faults?

A3: The system continuously monitors the key parameters and triggers alerts when any readings fall outside the defined safe range, enabling early detection of potential faults.

Q4: Can the 3500/65 be integrated with other monitoring systems?

A4: Yes, the 3500/65 is designed to be compatible with existing monitoring systems, allowing seamless integration for centralized monitoring and control.

Q5: What industries are best suited for the Bentley Nevada 3500/65?

A5: The 3500/65 is ideal for industries such as power generation, oil and gas, mining, chemical processing, and water treatment, where the reliability of rotating machinery is crucial.

Q6: What is the maximum operating temperature for the 3500/65?

A6: The operating temperature range for the 3500/65 is between -40°C to +70°C, making it suitable for both indoor and outdoor installations.

Q7: How is the 3500/65 mounted?

A7: The 3500/65 is mounted using a DIN rail, allowing for easy and secure installation in a variety of industrial environments.

Q8: How accurate is the Bentley Nevada 3500/65?

A8: The system offers high accuracy with deviations of no more than ±1% of reading or ±0.05% full scale.

Q9: How much does the 3500/65 weigh and what are its dimensions?

A9: The Bentley Nevada 3500/65 weighs 2.2 kg and has dimensions of 120 mm (height), 220 mm (width), and 180 mm (depth).

Q10: What communication protocols does the 3500/65 support?

A10: The Bentley Nevada 3500/65 supports Modbus RTU communication and 4-20mA analog output, ensuring compatibility with various industrial automation systems.

Authenticity guarantee

All product specifications are original and authentic imported products. We have an annual sales volume of 300 million yuan, and we only produce original and authentic products. All customers who cooperate with us directly online can enjoy low discounts.

Free warehouse

We have a complete range of product models, 80% of conventional models are in stock, and we have established channels in Asia, Africa, North America, South America, and Europe, effectively shortening the order processing time and satisfying customers in a timely manner.

Technical Team

Fast delivery. Spot goods can be shipped on the same day, and the delivery time transaction is 20% faster than that of peers on average, with a delivery time accuracy rate of 99%.

Thoughtful after-sales service

24-hour after-sales service guarantee team, professional and standardized management service system.