ProductPRODUCT

Featured products

Contact Us

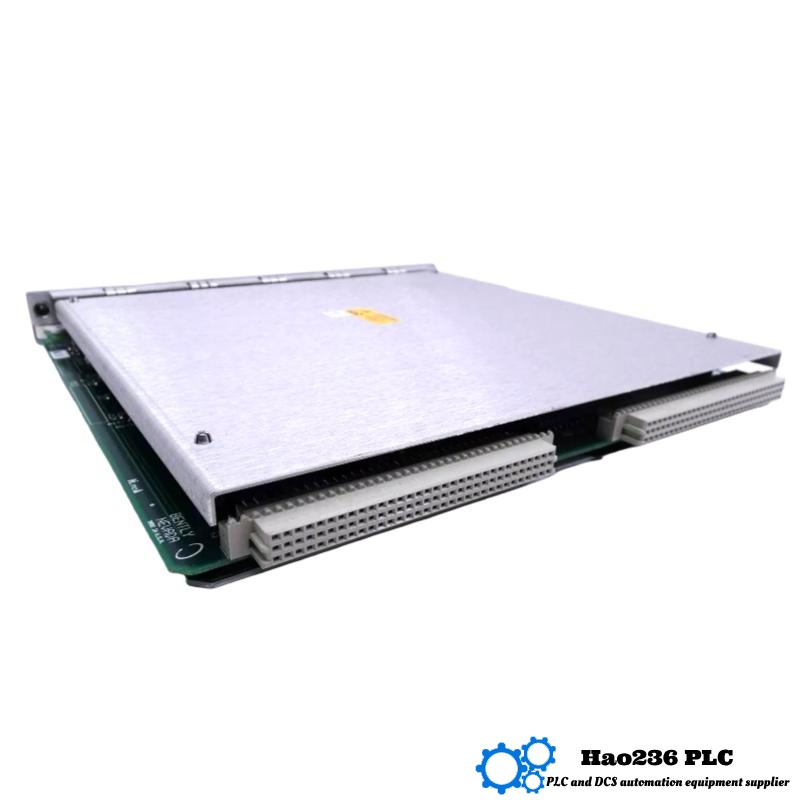

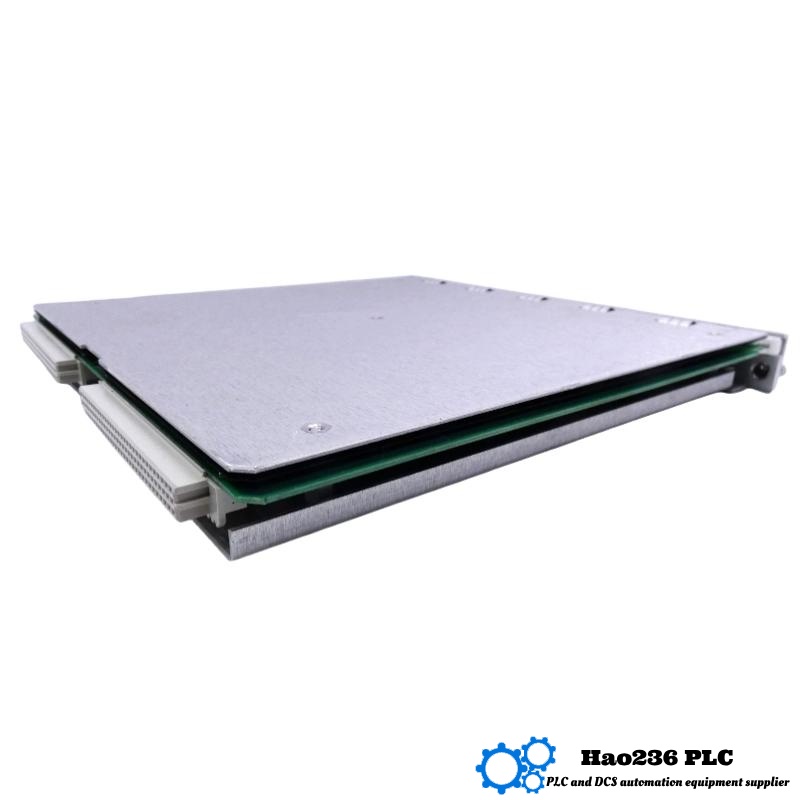

- Bently Nevada

- 3500/45 140072-04

- Position Monitor Module

- USA

- 241.3 mm × 24.4 mm × 99.1 mm

- 0.2kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 30

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| sales@plc-automations.com | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

1. Product Introduction: Bently Nevada 3500/45 140072‑04

The Bently Nevada 3500/45 140072‑04 is a four‑channel Position / Displacement Monitor Module in the 3500 machinery protection series. It is designed to monitor shaft and structural position phenomena including axial displacement, differential expansion, case expansion, and valve travel. It accepts a variety of position sensor inputs (such as LVDTs, proximity probes in some configurations, or potentiometers) and continuously evaluates the signals against user‑set thresholds. It is typically installed in a 3500 rack and works in concert with relay and output modules to provide machine protection, alarm, and diagnostic functions.

This variant (140072‑04) may differ from earlier versions (e.g. 140072‑02) in firmware, front connector layout, or minor performance refinements, but retains the core functional capabilities of the 3500/45 family.

2. Technical Specifications

Below is a table of the major parameters for 3500/45 140072‑04 (typical values where applicable):

| Parameter | Typical / Maximum Value |

|---|---|

| Model | 3500/45 140072‑04 |

| Number of Channels | 4 independent channels |

| Supported Sensor Types | AC LVDT, DC LVDT, potentiometer (rotary or linear) |

| Input Signal Range | ±10 Vdc (conditioned) |

| Output / Buffering | Buffered output per channel, for external monitoring |

| Alarm Functions | Alert / Danger comparisons; differential, expansion, valve position |

| Power Consumption | ≈ 10 W |

| Operating Temperature | –30 °C to +65 °C |

| Storage Temperature | –40 °C to +85 °C |

| Relative Humidity Tolerance | Up to 95% non‑condensing |

| Signal Processing / Filters | High/low pass filters, notch filters, composite, 1X/NX logic |

| Mounting / Rack Interface | Full-height front slot in 3500 rack |

| Dimensions (L × W × H) | 241.3 mm × 24.4 mm × 99.1 mm |

| Weight | 0.20 kg |

3. Applications

The 3500/45 140072‑04 module is suited for any rotating or position‑sensitive machinery where precise displacement or expansion monitoring is critical. Common applications include:

-

Axial Position Monitoring: For turbines, compressors, pumps — to detect axial movement of the shaft.

-

Differential Expansion Monitoring: In machines with moving casings, to track relative displacement between machine components under thermal loading.

-

Case Expansion / Deformation Monitoring: To detect casing distortion or thermal expansion under load.

-

Valve Position / Actuator Feedback: Monitoring valve spool or actuator movement to ensure correct control.

-

Protective Alarm Functions: Trigger alerts or shutdowns when movement exceeds safe limits.

-

Trending & Diagnostics: Recording displacement history for predictive maintenance.

Industries and equipment types in which this module is often used:

-

Fossil / Steam / Gas Turbines

-

Large Centrifugal Compressors

-

Pumps, Fans, Blowers

-

Petrochemical Process Machinery

-

Power Generation (conventional, cogeneration, combined cycle)

-

Paper / Pulp, Mining, Heavy Industry

This module offers flexibility in retrofits, upgrades, and new installations, especially where multiple displacement sensors are required in one system.

4. Advantages & Key Features

-

Multi‑channel capability: Handles four independent displacement channels in one module.

-

Sensor flexibility: Compatible with AC/DC LVDTs and potentiometers, enabling adaptation to different transducer types.

-

High signal fidelity: Includes built-in filtering and signal conditioning to reduce noise and interference.

-

Programmable alarm logic: Users can set alert and danger thresholds, with multiple modes (e.g. differential, total, valve position).

-

Real‑time monitoring: Continuous evaluation of position signals with buffered outputs for external use.

-

Compact footprint: Takes minimal rack space while providing full functionality.

-

System interoperability: Integrates seamlessly into the 3500 rack architecture alongside other modules for comprehensive machine protection.

-

Reliability in industrial environments: Designed for harsh conditions with wide temperature and humidity tolerance.

5. Brand & Series

-

Brand: Bently Nevada

-

Series / Platform: 3500 Machinery Protection System

The 3500 series is a modular, field-proven platform for vibration, displacement, temperature, and process monitoring of critical rotating machinery.

6. Related / Alternative Models in Same Series or Domain

Below are five modules in the 3500 family or closely related functionally, with basic parameter comparison.

| Model | Description / Function | Input Types / Functionality | Channels | Dimensions / Weight (approx) |

|---|---|---|---|---|

| 3500/45 140072‑04 | Displacement / Position Monitor (this module) | LVDTs, potentiometers | 4 | 241.3 × 24.4 × 99.1 mm, 0.20 kg |

| 3500/42M | Proximity + Seismic Vibration Monitor | Proximity + Vibration sensors | 2 / 4 | rack form size, ~0.75 kg |

| 3500/44M | Triple redundant vibration / displacement monitor | Vibration / displacement inputs | 4 | rack form size, ~0.76 kg |

| 3500/40M | Proximity displacement (Proximitor) monitor | Proximity probes | 4 | rack size, ~0.73 kg |

| 3500/46M | Multi‑mode dynamic / hydrodynamic measurement | Vibration, pressure, displacement | 4 | rack size, ~0.74 kg |

These modules broadly cover the spectrum of vibration, displacement, process, and hybrid monitoring, and they share compatible rack architecture.

7. Popular Models from the Same Brand (Bently Nevada)

Here are five well‑used or highly regarded modules (from the 3500 line or related lines) from the same brand, with parameter overviews:

| Model | Role / Application | Input / Output Type | Channels / Feature | Dimensions / Weight (approx) |

|---|---|---|---|---|

| 3500/60 | Temperature / RTD / Thermocouple Monitor | RTD, thermocouple | 6 channels | rack form size, ~0.74 kg |

| 3500/22M | Communications / Gateway Interface | Ethernet, serial, digital I/O | system interface | rack footprint, ~0.80 kg |

| 3500/94M | Display / Local Monitoring Module | VGA / display output | user interface | rack size, ~0.82 kg |

| 3300 XL Proximitor | Standalone proximity transducer system | Proximity probes | n/a (transducer node) | compact sensor housing, ~0.35 kg |

| 1900/65A | Standalone vibration monitor | Acceleration, velocity | 2 channels | compact unit, ~0.65 kg |

8. FAQ – 10 Questions & Answers (Q & A)

Q1: What exactly does the 3500/45 140072‑04 monitor?

A1: It monitors positional variables such as axial shaft position, differential expansion between components, case expansion, and valve travel or actuator position.

Q2: How many channels does the module have?

A2: It has four independent channels.

Q3: What sensor types can be used with it?

A3: It supports AC LVDTs, DC LVDTs, and potentiometers (linear or rotary types).

Q4: What is the operating temperature range?

A4: –30 °C to +65 °C for operating, and –40 °C to +85 °C for storage.

Q5: What is the physical size and weight?

A5: Dimensions are 241.3 mm × 24.4 mm × 99.1 mm, and weight is about 0.20 kg.

Q6: How does the module produce alarms or warnings?

A6: Each channel’s processed signal is compared to user‑set alert and danger thresholds; if exceeded, alerts or shutdown commands may be triggered.

Q7: Can channels be used for different measurement types simultaneously?

A7: Yes — each channel can be configured independently for position, differential, valve, or expansion functions.

Q8: Is this module hot‑swappable?

A8: No, it should not be inserted or removed while powered; power down the rack before module changes.

Q9: How does it integrate into a full machinery protection system?

A9: It resides in the 3500 rack, communicates with relay modules, output modules, and system gateways to form a holistic protection and monitoring topology.

Q10: Are there any constraints in installations (environmental, wiring)?

A10: Yes — proper grounding, shielding of sensor cables, avoidance of sensor cross‑talk, and adherence to environmental limits are essential for reliable performance.

Authenticity guarantee

All product specifications are original and authentic imported products. We have an annual sales volume of 300 million yuan, and we only produce original and authentic products. All customers who cooperate with us directly online can enjoy low discounts.

Free warehouse

We have a complete range of product models, 80% of conventional models are in stock, and we have established channels in Asia, Africa, North America, South America, and Europe, effectively shortening the order processing time and satisfying customers in a timely manner.

Technical Team

Fast delivery. Spot goods can be shipped on the same day, and the delivery time transaction is 20% faster than that of peers on average, with a delivery time accuracy rate of 99%.

Thoughtful after-sales service

24-hour after-sales service guarantee team, professional and standardized management service system.