ProductPRODUCT

Featured products

Contact Us

- Bently Nevada

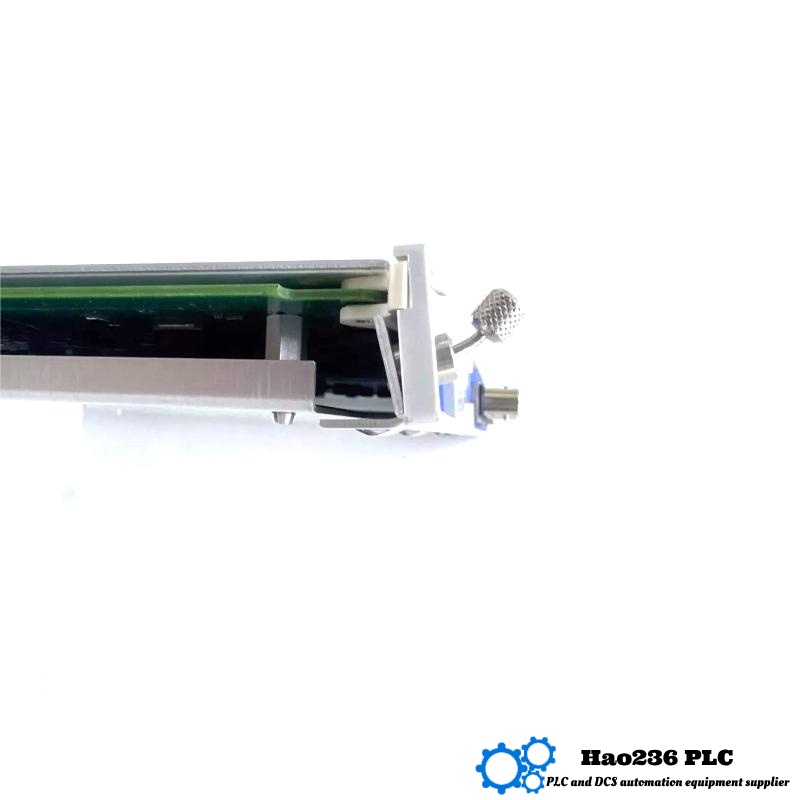

- 3500/42 125672-02

- Proximitor/Seismic Monitor Module

- USA

- 2.6 × 25.8 × 24.0 cm

- 0.9kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 78

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| sales@plc-automations.com | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

📦 Product Overview – Bently Nevada 3500/42 (125672-02)

🔹 Product Introduction

The Bently Nevada 3500/42 Proximitor/Seismic Monitor is a high-performance monitoring module designed to measure and protect rotating machinery by processing input signals from proximity probes and seismic sensors. It provides critical real-time data related to vibration, displacement, and acceleration, ensuring that rotating equipment operates within safe parameters.

This module is commonly used in conjunction with other components of the Bently Nevada 3500 Series system, forming a comprehensive platform for machinery protection and condition monitoring.

🔹 Brand & Series

-

Brand: Bently Nevada

-

Series: 3500 Series

-

Module Name: Proximitor / Seismic Monitor

-

Model Number: 3500/42

-

Part Number: 125672-02

🔹 Key Applications

-

Rotating Equipment Protection – Turbines, compressors, motors, pumps

-

Vibration Monitoring – Real-time detection of abnormal vibrations

-

Thrust Position & Differential Expansion Measurement

-

Seismic Monitoring – Monitoring casing or base movement

-

Condition-Based Maintenance – Enables predictive diagnostics

🔹 Product Advantages

-

Multifunctional: Measures vibration, position, and seismic activity

-

High Accuracy: Ensures precise detection of mechanical anomalies

-

Modular Design: Easy to integrate within the 3500 rack

-

Real-Time Processing: Fast response to input signal changes

-

Flexible Configuration: Supports different sensor types and signal conditioning

-

Industrial-Grade Reliability: Designed for harsh industrial environments

🔹 Technical Specifications (Table Format)

| Parameter | Value |

|---|---|

| Model | 3500/42 125672-02 |

| Channels | 4 (independent input channels) |

| Sensor Inputs | Proximity probes, seismic sensors (accelerometers) |

| Input Sensitivity | 100 mV/mil, 200 mV/mil (configurable) |

| Output Type | 4–20 mA recorder output, buffered output |

| Output Resolution | ~0.37 µA per bit |

| Frequency Response | 4 Hz to 4,000 Hz (typical for direct filter) |

| Signal Processing | Gap filter, Not 1X, Smax, 1X/2X filters |

| Buffered Output Impedance | 550 Ω |

| Power Consumption | ~7.7 W |

| Operating Temperature | -30°C to +65°C |

| Dimensions (cm) | 2.6 × 25.8 × 24.0 |

| Weight (kg) | 0.9 kg |

| Recorder Output Range | 0–20 mA (typically 4–20 mA configurable) |

| Relay Support | Works with 3500/32M, 3500/33 modules |

| LED Indicators | OK, TX/RX, Bypass |

🔹 5 Related Models (Same Series or Functionally Related)

| Model | Function | Key Feature |

|---|---|---|

| 3500/32M | Relay Module (4-Channel) | Outputs alarms as dry contact relays |

| 3500/33 | Relay Module (16-Channel) | Dense alarm relay output |

| 3500/44M | Aeroderivative Monitor | Used for aeroderivative gas turbines |

| 3500/45 | Position Monitor | Measures thrust position and differential expansion |

| 3500/50 | Tachometer Module | Speed measurement using Keyphasor input |

🔹 5 Popular Models from the Same Brand

| Model | Function | Specifications |

|---|---|---|

| 3500/22M | Transient Data Interface (TDI) | Communication gateway for the rack |

| 3500/60 | RTD Temperature Monitor | Accepts RTD temperature sensors (4 channels) |

| 3500/61 | Thermocouple Monitor | Accepts thermocouple inputs |

| 3500/65 | High-Density Temperature Monitor | 16-channel temperature input |

| 3500/53 | Overspeed Detection Module | Used for critical turbine overspeed protection |

🔹 Top 10 FAQs (QA Format)

Q1: What does the 3500/42 module monitor?

A1: It monitors vibration, displacement, thrust position, and seismic movement using proximity and seismic sensors.

Q2: How many channels does it support?

A2: It supports 4 independent input channels, each configurable for different types of measurements.

Q3: Can it work with both proximity probes and seismic sensors?

A3: Yes, the module is designed to process signals from both types of sensors.

Q4: What kind of outputs does it provide?

A4: It offers 4–20 mA current outputs per channel and buffered transducer outputs for diagnostics.

Q5: Is it compatible with other 3500 modules?

A5: Yes, it integrates with relay modules (e.g., 3500/32M), Keyphasor modules (3500/50), and the TDI module.

Q6: What is the response time of the module?

A6: The module typically updates output values in less than 100 milliseconds.

Q7: Can I configure filters and alarms?

A7: Yes, users can set bandpass filters, alarm thresholds, and logic per channel.

Q8: How is sensor health monitored?

A8: The module uses OK status checks and LED indicators to monitor transducer health.

Q9: What does the “Bypass” LED mean?

A9: The bypass LED indicates that a channel is intentionally disabled or excluded from triggering alarms.

Q10: What environments is it suitable for?

A10: It is built for industrial environments such as power plants, oil & gas facilities, and heavy machinery operations.

Authenticity guarantee

All product specifications are original and authentic imported products. We have an annual sales volume of 300 million yuan, and we only produce original and authentic products. All customers who cooperate with us directly online can enjoy low discounts.

Free warehouse

We have a complete range of product models, 80% of conventional models are in stock, and we have established channels in Asia, Africa, North America, South America, and Europe, effectively shortening the order processing time and satisfying customers in a timely manner.

Technical Team

Fast delivery. Spot goods can be shipped on the same day, and the delivery time transaction is 20% faster than that of peers on average, with a delivery time accuracy rate of 99%.

Thoughtful after-sales service

24-hour after-sales service guarantee team, professional and standardized management service system.