ProductPRODUCT

Featured products

Contact Us

- Bently Nevada

- 3500/25 126648-02+128718-01

- Enhanced Keyphasor Module

- USA

- 267 mm x 160 mm x 55 mm

- 1.2kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 61

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

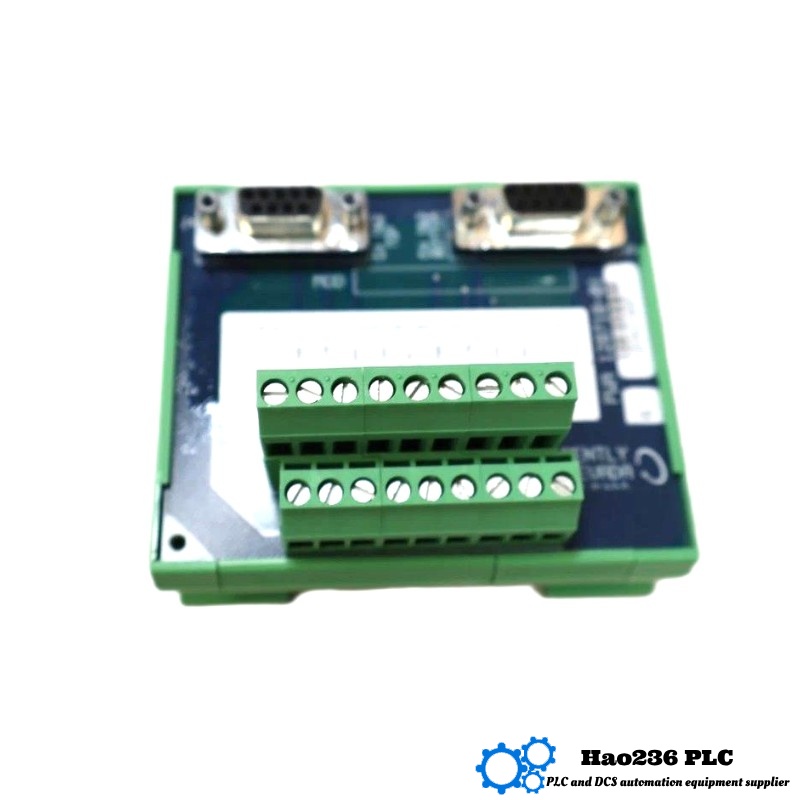

Product Overview: Bently Nevada 3500/25 126648-02 + 128718-01

Product Introduction:

The Bently Nevada 3500/25 126648-02 + 128718-01 is part of the renowned 3500 series of machinery protection and condition monitoring systems. This model is designed specifically to monitor the vibration and health of critical rotating machinery in demanding industrial applications. By offering real-time data and advanced diagnostic features, the 3500/25 system helps to identify potential problems before they lead to machinery failure. This reduces the risk of unplanned downtime, extending the lifespan of machinery and improving operational efficiency.

This particular model is commonly used in heavy industries such as power generation, oil and gas, chemical processing, and manufacturing, where the performance of rotating equipment is critical. The system offers robust environmental protection, allowing it to perform reliably in challenging conditions like extreme temperatures, vibrations, and dust.

Product Features:

-

Real-Time Vibration Monitoring: Monitors the vibration levels of machinery, ensuring early detection of faults or irregularities.

-

Integrated Diagnostics: Provides detailed diagnostics to help identify the specific causes of vibration issues.

-

Rugged Design: With an industrial-grade build, the system operates effectively in harsh environments.

-

Flexible Installation: Can be easily mounted on panels or DIN rails, with adaptable communication options to suit a variety of industrial setups.

-

Advanced Connectivity: Supports Modbus, Profibus, and Ethernet for integration with other monitoring systems.

Product Specifications:

| Specification | Details |

|---|---|

| Model Number | 3500/25 126648-02 + 128718-01 |

| Type | Vibration Monitoring and Protection |

| Dimensions (L x W x H) | 267 mm x 160 mm x 55 mm |

| Weight | 1.2 kg |

| Input Voltage | 24V DC |

| Measurement Range | 0 – 2000 Hz |

| Operating Temperature | -20°C to 60°C |

| Environmental Protection | IP65 |

| Display Type | LED Indicators |

| Mounting | Panel or DIN Rail |

| Communication Protocols | Ethernet, Modbus, Profibus |

Product Application:

The Bently Nevada 3500/25 is used to monitor critical machinery in environments where performance and reliability are paramount. Common applications include:

-

Gas Turbines: For power generation, where vibration monitoring ensures smooth operation.

-

Compressors: In industries like oil and gas, where compressor failure can cause significant downtime.

-

Electric Motors: Used in various industrial processes, including heavy manufacturing.

-

Pumps: Especially in chemical and water treatment plants, where pump failure can lead to disruptions in production.

-

Fans and HVAC Systems: Essential for maintaining air flow and pressure in industrial facilities.

By offering continuous monitoring of vibration and health metrics, this product helps in minimizing unscheduled downtime and maintenance costs, thus enhancing operational efficiency and the lifespan of machinery.

Product Advantages:

-

Proactive Monitoring: Detects faults early, allowing for timely maintenance and reducing the risk of unplanned downtime.

-

Comprehensive Diagnostics: Advanced diagnostic capabilities allow operators to pinpoint the specific causes of machine issues.

-

Durability: The system’s rugged design and IP65 protection make it resistant to harsh environmental conditions.

-

User-Friendly Interface: Clear indicators and easy-to-navigate diagnostics ensure a seamless user experience.

-

Scalable Integration: Supports integration with other Bently Nevada systems, making it flexible and scalable as part of a broader machinery protection program.

Brand:

-

Brand: Bently Nevada

-

Brand Overview: A leading provider of condition monitoring and machinery protection systems, Bently Nevada is well-known for its high-performance solutions that help industries maintain equipment reliability and reduce costs associated with unexpected downtime.

Series:

-

Series: Bently Nevada 3500 Series

Recommended Products in the Same Series or Related Models

| Model Number | Key Features | Weight (kg) | Dimensions (L x W x H) |

|---|---|---|---|

| 3500/42 | Vibration and temperature monitoring system | 1.0 | 250 mm x 150 mm x 50 mm |

| 3500/53 | Condition monitoring for industrial compressors | 1.3 | 280 mm x 160 mm x 55 mm |

| 3500/22 | Machinery protection and vibration monitoring system | 1.2 | 270 mm x 155 mm x 50 mm |

| 3500/90 | High-speed machinery vibration monitoring system | 1.0 | 240 mm x 140 mm x 45 mm |

| 3500/77 | Protection for power generation and critical systems | 1.6 | 275 mm x 160 mm x 60 mm |

Recommended Popular Models from the Same Brand

| Model Number | Key Features | Weight (kg) | Dimensions (L x W x H) |

|---|---|---|---|

| 3500/42M | Vibration and displacement sensor for machinery | 1.1 | 250 mm x 150 mm x 50 mm |

| 3500/20 | 3-channel vibration system for large turbines | 1.5 | 280 mm x 160 mm x 60 mm |

| 3500/35 | Diagnostic system for gas turbines | 1.4 | 270 mm x 155 mm x 50 mm |

| 3500/95 | Protection system for high-efficiency motors | 1.3 | 260 mm x 150 mm x 55 mm |

| 3500/53M | Monitoring system for industrial compressors | 1.3 | 275 mm x 160 mm x 55 mm |

FAQ (10 Questions and Answers)

Q1: What does the Bently Nevada 3500/25 monitor?

A1: The Bently Nevada 3500/25 primarily monitors the vibration and health of rotating machinery, such as gas turbines, compressors, and motors, helping to detect early signs of mechanical issues.

Q2: How does the system help reduce unplanned downtime?

A2: By continuously monitoring critical machinery parameters and providing early alerts for any abnormal vibration or performance changes, the system allows operators to take corrective actions before failures occur.

Q3: What is the environmental protection rating of the 3500/25?

A3: The 3500/25 has an IP65 environmental protection rating, meaning it is dust-tight and can withstand water jets, making it suitable for harsh industrial environments.

Q4: Can the 3500/25 be integrated with other monitoring systems?

A4: Yes, the system supports communication protocols such as Ethernet, Modbus, and Profibus, enabling integration with other Bently Nevada or third-party monitoring systems.

Q5: What is the typical installation method for the 3500/25?

A5: The 3500/25 can be mounted on panels or DIN rails, offering flexibility in installation depending on the setup and space available.

Q6: What is the temperature range of the 3500/25?

A6: The system operates in a temperature range from -20°C to 60°C, allowing it to function effectively in various industrial environments.

Q7: How is data presented to the user?

A7: The 3500/25 uses LED indicators for status display, along with real-time diagnostics, making it easy for operators to assess the condition of machinery.

Q8: Is the 3500/25 suitable for use in hazardous environments?

A8: Yes, with its IP65 rating, the 3500/25 is designed to function reliably in harsh, dusty, and potentially hazardous environments.

Q9: What is the weight of the Bently Nevada 3500/25?

A9: The weight of the 3500/25 is 1.2 kg, making it lightweight and easy to handle during installation and maintenance.

Q10: What industries typically use the Bently Nevada 3500/25?

A10: The 3500/25 is commonly used in industries such as power generation, oil and gas, chemical processing, and manufacturing, where machinery reliability is crucial to operations.