ProductPRODUCT

Featured products

Contact Us

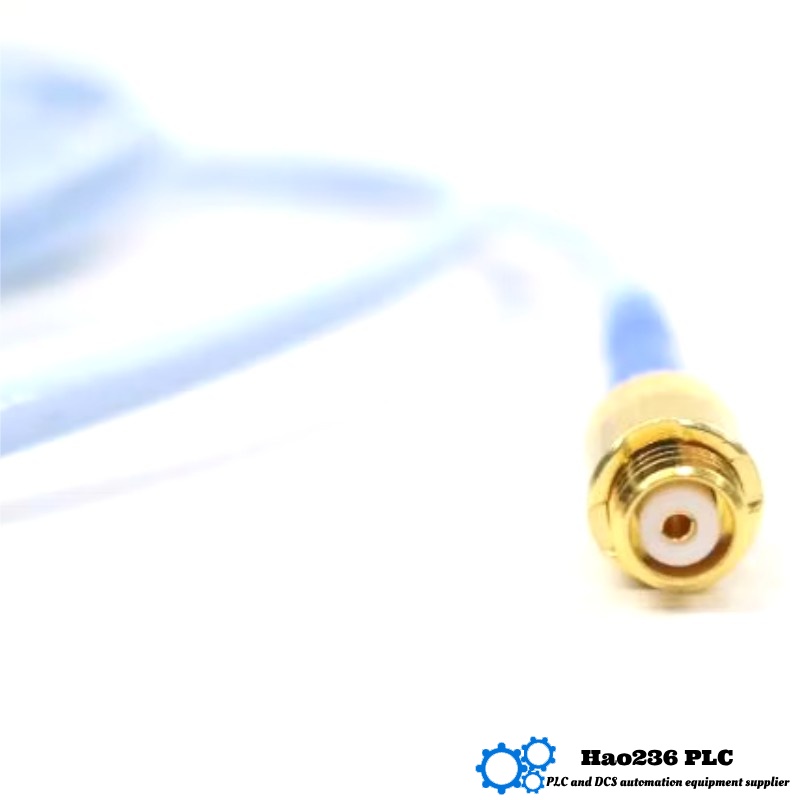

- Bently Nevada

- 330130-080-10-00

- 3300 XL 8mm Extension Cable

- USA

- 8.0 meters

- 0.35kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 148

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Product Overview — Bently Nevada 330130‑080‑10‑00

Product Introduction

The 330130‑080‑10‑00 is believed to be an eddy‑current proximity (Proximitor) sensor of the 3300 / 3300 XL family. It likely has an 8 mm probe tip (“080”) and is used for measuring shaft displacement, vibration, gap, or relative movement without contact. The “10‑00” suffix likely indicates cable/mounting option or extension variant, possibly standard non‑approved version depending on suffix meaning.

This kind of sensor is used in machinery protection systems, enabling continuous monitoring of machine health via displacement/vibration data to detect misalignment, rotor rubs, bearing wear, and to serve as speed/Keyphasor reference in some installations.

Technical Specifications (Inferred / Approximate)

| Parameter | Estimated / Typical Value |

|---|---|

| Model | 330130‑080‑10‑00 |

| Brand | Bently Nevada |

| Series | 3300 / 3300 XL Proximitor / Proximity Sensor Series |

| Probe Tip Diameter | ~ 8 mm (nominal, inferred) |

| Cable / Mounting Option | Option “10” likely refers to a particular cable length or mounting style |

| Suffix “00” | Possibly no extra agency approvals; standard version |

| Output Sensitivity | ~ 200 mV/mil (≈ 7.87 V/mm) (common for 8 mm series probes) |

| Operating Temperature Range | Roughly ‑40 °C to +100‑125 °C depending on housing & cable |

| Storage Temperature | About ‑40 °C to +105‑125 °C |

| Weight | ~ 0.30‑0.35 kg (probe + standard cable mounting) |

| Dimensions | Probe head ~8 mm diameter; housing ~8‑10 cm length (depending on cable); approximate body housing ~ few cm cross‑section |

| Mounting / Housing | Panel or DIN mount, standard 3300/XL mount footprint |

| Environmental / Ruggedness | Resistant to industrial vibration, moderate moisture/humidity; possibly EMI/RFI immunity depending on specification |

Applications

-

Shaft displacement monitoring in turbines / compressors / pumps

-

Vibration monitoring on rotating machinery

-

Bearing condition monitoring, detecting misalignment, rotor rubs, rotor vibration amplitude

-

Use as speed / Keyphasor reference output in some protection systems

-

Petrochemical, power generation, mining, paper, marine, and other heavy industries

Advantages

-

Non‑contact measurement avoids wear and reduces mechanical failure risk

-

High sensitivity and precise output help detect small deviations early

-

8 mm probe style offers robust tip and good mechanical durability

-

Likely compatible with existing 3300 / 3300 XL extension cables and electronics, easing replacement / upgrade

-

Probably lower cost standard version (“00” suffix) for non‑hazard or non‐certified installations if that holds

-

Standard temperature range allows broad industrial deployment

Brand & Series

-

Brand: Bently Nevada

-

Series: 3300 / 3300 XL Proximitor (proximity‑transducer / displacement sensor)

Related / Similar Models in the Same Series

Here are 5 models in the 3300 / 3300 XL proximity sensor family, with known parameters, to compare with the 330130‑080‑10‑00:

| Model | Application / Purpose | Output / Sensitivity | Dimensions / Weight | Distinctive Traits |

|---|---|---|---|---|

| 330100‑90‑05 | 5‑mm style probe, long cable, agency approved version | Standard proximity output; high resolution | 7.8 cm × 6.0 cm × 6.5 cm; 0.22 kg | Longer cable; tighter gap version |

| 330180‑50‑00 | 8‑mm style XL probe, panel mount, standard cable | Same sensitivity; 8 mm probe | ~ 0.35 kg | XL build; robust housing |

| 330180‑91‑00 | 8 mm probe + 9.0 m cable option | Standard output; extended distance | ~ 0.23 kg for sensor housing | Long reach; for installations where distance matters |

| 330130‑080‑02‑05 | 8 mm probe, with “02” cable/mount option and approvals | Similar output | ~ 0.35 kg (probe + cable) | Approvals and cable/mount variants |

| 330130‑040‑00‑05 | 5 mm probe style; smaller gap or tighter mounting | Similar sensitivity; smaller tip | Slightly lighter, smaller cross‑section | Alternative for compact mounting |

Popular Peer Models from the Same Brand

Here are five other well‑used Bently Nevada models, useful for comparison or complementing usage:

| Model | Application / Purpose | Dimensions / Weight | Key Features |

|---|---|---|---|

| 330180‑50‑05 | 8 mm XL Proximitor with medium cable & approvals | ~ same size; ~0.35‑0.40 kg | Good balance between reach and robustness |

| 330180‑91‑05 | Long cable 9.0m version with approvals | ~ lighter housing; ~0.25‑0.30 kg | Extended cable; global approved version |

| 330100‑50‑00 | Short cable or simpler version, 5 mm probe | ~0.29 kg | Compact; for less demanding mounting or smaller targets |

| 330780‑90‑00 | High‑temperature or ruggedized version in 8 mm class | ~0.40‑0.45 kg | Designed for harsher or hotter environments |

| 330280‑110‑01 | Larger probe body; possibly higher protection or housing | ~0.198 kg for sensor body; full system heavier | Alternate housing styles; heavier build; extended durability |

FAQs (QA)

-

Q: What is the probe tip diameter of 330130‑080‑10‑00?

A: It is approximately 8 mm based on the “080” code in the model number. -

Q: What temperature range can this sensor likely withstand?

A: Approximately ‑40 °C to +100‑125 °C, depending on cable and housing. -

Q: What is its estimated weight including probe + cable?

A: Roughly 0.30‑0.35 kg, though actual weight depends on cable length. -

Q: What kind of output sensitivity is expected?

A: Around 200 mV/mil (≈ 7.87 V/mm), typical for 8 mm proximity sensors in this family. -

Q: Is this model likely certified or agency‑approved?

A: The “10‑00” suffix likely indicates a standard (non‑hazard or non‑certified) version; it may lack certain approvals unless specified. -

Q: Can this sensor be used for both static (displacement) and dynamic (vibration) measurements?

A: Yes, sensors of this type are generally usable for both static gap / displacement monitoring and dynamic vibration sensing when paired with appropriate electronics. -

Q: What mounting options are there?

A: Likely panel mount or standard 3300 series mount; cable routing and extension options may vary. -

Q: What industries or machines is this sensor suited for?

A: Suitable for turbines, compressors, motors, pumps—especially in industrial plants, power generation, oil & gas, mining. -

Q: What kind of cable length or connector styles might “10‑00” imply?

A: Probably a standard cable, not an extended one; possibly basic connector style. -

Q: What environmental factors must be considered when using this sensor?

A: Vibration tolerance, moisture (non‑condensing humidity), EMI/RFI interference, consistency of target material and surface, proper gap alignment, temperature extremes.