ProductPRODUCT

Featured products

Contact Us

- Bently Nevada

- 330106-05-30-50-02-00

- 8 mm Reverse Mount Proximity Probe

- USA

- 5.0 meters

- 1.62kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 168

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

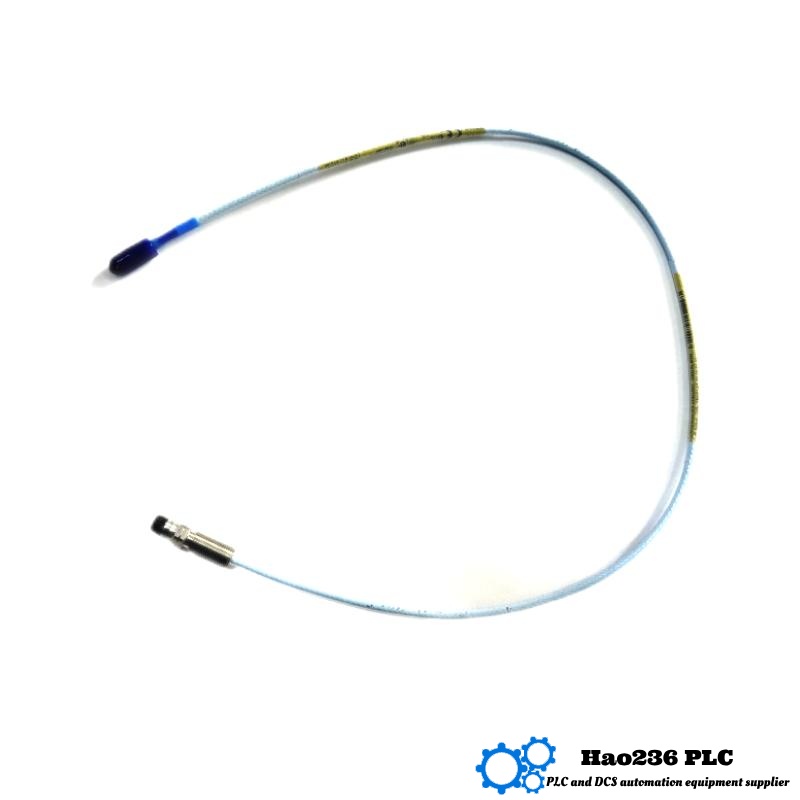

Bently Nevada 330106-05-30-50-02-00 8 mm Reverse Mount Proximity Probe

Product Overview

The Bently Nevada 330106-05-30-50-02-00 8 mm Reverse Mount Proximity Probe is an advanced, high-precision measurement tool used primarily for rotor shaft vibration monitoring. As part of Bently Nevada’s 3300 XL series, this proximity probe is designed for use in harsh industrial environments, where the precision of vibration measurements is critical for predictive maintenance and system performance optimization. The 8 mm reverse mount design allows for easy installation in tight spaces while offering superior performance and reliability.

Designed with a length of 5.0 meters and weighing 1.62 kg, this probe provides accurate displacement measurements, ensuring early detection of mechanical issues in rotating machinery. Its durability and consistent accuracy make it an invaluable tool for condition monitoring, enabling you to optimize machine uptime and prevent costly downtime.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | 330106-05-30-50-02-00 |

| Type | 8 mm Reverse Mount Proximity Probe |

| Total Length | 5.0 meters |

| Weight | 1.62 kg |

| Probe Diameter | 8 mm |

| Mounting Type | Reverse Mount |

| Sensing Range | 0 to 10 mm |

| Output Signal | 4 to 20 mA |

| Operating Temperature | -40°C to +120°C |

| Protection Class | IP67 |

| Frequency Response | Up to 10 kHz |

| Shock Resistance | 100 g for 6 ms |

Applications

The Bently Nevada 330106-05-30-50-02-00 8 mm Reverse Mount Proximity Probe is primarily used in industrial monitoring systems for condition-based maintenance. The applications include:

-

Turbines and Compressors: Monitoring vibrations in critical rotating equipment such as turbines, compressors, and pumps.

-

Motors and Generators: Vibration monitoring of electric motors, generators, and alternators to prevent mechanical failures.

-

Fans and Blowers: Detecting early signs of imbalance or misalignment in high-speed fans and blowers.

-

Industrial Machinery: Proactive maintenance in machinery such as crushers, mills, and other heavy-duty equipment.

-

Condition Monitoring Systems: Integration with Bently Nevada’s monitoring systems for real-time diagnostics and data analytics.

Advantages

-

High Precision: Provides accurate and reliable displacement measurements to detect any mechanical faults such as imbalance, misalignment, or wear.

-

Durability: Built to endure harsh industrial environments with IP67 protection, it resists dust, moisture, and high temperatures.

-

Compact Design: The 8 mm reverse mount design allows for easier installation in tight spaces while maintaining high-performance standards.

-

Optimized Performance: The probe’s excellent frequency response and temperature range (up to 120°C) ensure reliable operation in a variety of conditions.

-

Low Maintenance: Designed for minimal maintenance and high reliability, reducing the need for frequent recalibration and maintenance.

-

Enhanced Machine Uptime: Early detection of faults prevents machine failure, contributing to increased uptime and reduced operational costs.

Brand: Bently Nevada

Bently Nevada, a division of Baker Hughes, is a global leader in industrial machinery diagnostics and condition monitoring. Their products, including the 3300 XL series, are known for their high-quality, precision instrumentation and systems that help organizations increase productivity, reduce downtime, and improve safety across various industries such as oil and gas, power generation, and manufacturing.

Related Models

| Model | Description | Key Parameter |

|---|---|---|

| 330104-05-30-50-02-00 | 8 mm Reverse Mount Proximity Probe | Length: 5.0 meters |

| 330107-05-30-50-02-00 | 8 mm Reverse Mount Proximity Probe | Operating Temperature: -40°C to +120°C |

| 330102-05-30-50-02-00 | 8 mm Standard Mount Proximity Probe | Length: 5.0 meters |

| 330108-05-30-50-02-00 | 8 mm Reverse Mount Proximity Probe (longer range) | Sensing Range: 0 to 12 mm |

| 330112-05-30-50-02-00 | 8 mm Reverse Mount Proximity Probe (high-frequency) | Frequency Response: Up to 20 kHz |

Popular Bently Nevada Models

| Model | Description | Key Parameter |

|---|---|---|

| 330106-05-30-10-02-05-05 | 8 mm Proximity Probe, Reverse Mount | Operating Temp: -40°C to +120°C, Cable Length: 5 meters |

| 330106-05-30-10-02-BR | 8 mm Proximity Probe, Brazed Tip | Measurement Range: 0-10 mm, Mounting Type: Threaded |

| 330106-05-30-10-02-CN | 8 mm Proximity Probe, CN Mount | Response Time: <1 ms, Cable Length: 2 meters |

| 330106-05-30-10-02-03 | 8 mm Proximity Probe, Standard | Frequency Range: 10 Hz – 1 kHz, Cable Material: PVC |

| 330106-05-30-10-02-06 | 8 mm Proximity Probe, Custom Cable | Operating Temp: -20°C to +80°C, Cable Length: 6 meters |

FAQ

Q1: What is the purpose of the Bently Nevada 330106-05-30-50-02-00 proximity probe?

A1: The probe is designed for monitoring rotor shaft vibrations in critical machinery, providing early fault detection to avoid expensive downtime and failures.

Q2: What is the sensing range of this proximity probe?

A2: The sensing range of the probe is from 0 to 10 mm.

Q3: How long is the cable of this proximity probe?

A3: The total cable length of the probe is 5.0 meters.

Q4: What is the frequency response of this proximity probe?

A4: The probe has a frequency response of up to 10 kHz.

Q5: What is the operating temperature range for the probe?

A5: The operating temperature range is from -40°C to +120°C.

Q6: Can this probe be used in hazardous environments?

A6: Yes, the probe has IP67 protection, making it resistant to dust and moisture, suitable for harsh industrial environments.

Q7: How is this proximity probe mounted?

A7: The 330106-05-30-50-02-00 model is a reverse mount probe, designed for easy installation in tight spaces.

Q8: What type of output signal does this proximity probe provide?

A8: The probe provides a 4 to 20 mA output signal for easy integration into monitoring systems.

Q9: How does this probe improve maintenance operations?

A9: By providing accurate vibration data, it helps predict potential failures, enabling maintenance teams to address issues before they cause damage or unplanned downtime.

Q10: Is the probe compatible with Bently Nevada’s 3500 series monitoring systems?

A10: Yes, the 330106-05-30-50-02-00 probe is fully compatible with Bently Nevada’s 3500 condition monitoring system.