ProductPRODUCT

Featured products

Contact Us

- Bently Nevada

- 330104-13-20-50-02-00

- 8 mm Proximity Probe (Metric)

- USA

- 5.0 meters

- 1.615kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 173

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

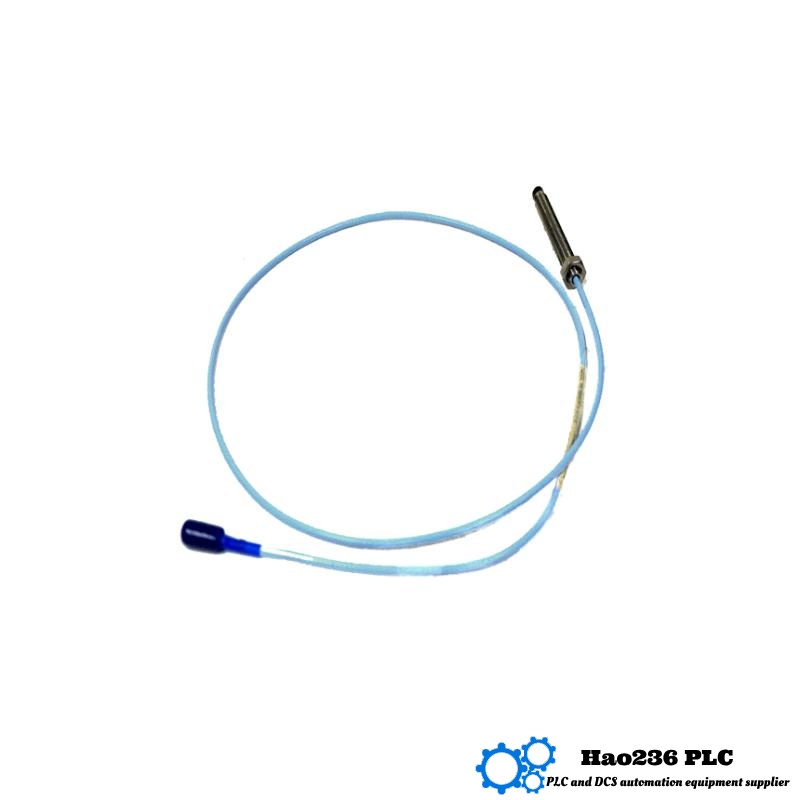

Bently Nevada 330104-13-20-50-02-00 8mm Proximity Probe, Metric

Product Introduction

The Bently Nevada 330104-13-20-50-02-00 is a high-precision 8mm proximity probe designed for use in rotating machinery monitoring and vibration analysis. As part of the 3300 XL Series, this probe is engineered for high reliability and performance in industrial applications where vibration monitoring is critical for machinery health diagnostics.

This metric version of the 330104-13 probe provides a 5.0-meter total length of cable, offering flexibility for various types of machinery installations. Designed for precise measurement of shaft displacement and vibration amplitude, it enables operators to effectively monitor the condition of machinery in real time, ensuring early detection of faults and reducing the risk of unexpected downtime or catastrophic failures.

The Bently Nevada 330104 proximity probe is compatible with various Bently Nevada vibration monitoring systems, offering integration into data acquisition systems for continuous asset condition monitoring.

Product Parameters

| Parameter | Specification |

|---|---|

| Total Length | 5.0 meters |

| Weight | 1.615 kg |

| Probe Diameter | 8mm |

| Cable Type | Shielded, high temperature |

| Application | Vibration and displacement monitoring |

| Output Type | Analog displacement signal |

| Measuring Range | Up to 100 mils (2.54 mm) displacement |

| Mounting | Standard probe mounting |

| Temperature Range | -40°C to +120°C |

| Operating Pressure | 0 to 100 bar (depends on housing) |

Applications

The Bently Nevada 330104-13-20-50-02-00 proximity probe is ideal for rotating machinery condition monitoring and is widely used across various industries for:

-

Turbines: Monitoring turbine shaft displacement and vibration in power plants.

-

Motors and Generators: Detecting imbalance, misalignment, and bearing wear in large motors and generators.

-

Pumps and Compressors: Ensuring the health of pumps and compressors in petrochemical, water treatment, and industrial manufacturing plants.

-

Industrial Fans and Blowers: Monitoring vibration in large-scale fan systems to prevent failure.

-

Gearboxes and Couplings: Providing accurate feedback on shaft movement to help detect issues with gears or couplings early.

-

Paper Mills and Steel Mills: Vibration analysis in high-speed, heavy-duty industrial applications to ensure smooth operation.

Advantages

-

High Precision Measurement: The 8mm proximity probe offers accurate displacement measurements, allowing for detailed diagnostics of machinery health.

-

Durable Design: Built to withstand harsh industrial environments with a wide temperature range of -40°C to +120°C, the probe ensures long-term reliability.

-

Easy Installation: With standard probe mounting, the 330104-13 probe integrates easily with existing systems, minimizing downtime during setup.

-

Enhanced Fault Detection: By monitoring vibration and displacement in real time, the probe enables early detection of potential faults, preventing costly failures and unplanned downtime.

-

Long Cable Length: The 5.0-meter cable provides flexibility for installation in larger systems or machinery that require longer cable runs.

-

Compatibility: Works seamlessly with Bently Nevada’s 3300 XL Series and other condition monitoring systems, enhancing system performance and reducing maintenance costs.

Brand and Series

Brand: Bently Nevada

Series: 3300 XL Series

Bently Nevada, is recognized as a global leader in vibration monitoring and condition monitoring systems for industrial assets. The 3300 XL Series is one of the most advanced solutions available for continuous monitoring of rotating machinery, providing real-time vibration analysis, fault detection, and performance optimization.

Recommended Related Products

| Model | Description | Key Parameters |

|---|---|---|

| 330103-13-20-50-02-00 | 5mm Proximity Probe, Metric | 5.0 meters cable length, Analog displacement signal |

| 330104-13-20-50-02-10 | 8mm Proximity Probe with Enhanced Cable | 10.0 meters cable, higher temperature rating |

| 330130-20-00-00 | Proximity Probe with extended range | High range displacement, 5.0 meters cable |

| 330104-13-20-50-02-01 | 8mm Probe with customized cable length | 2.0 meters cable, Analog signal output |

| 330106-13-20-50-02-00 | Dual channel proximity probe | Two probes, 5.0 meters cable, for dual-channel systems |

Popular Bently Nevada Products

| Model | Description | Key Parameters |

|---|---|---|

| 330104-08-16-20-02-05 | Digital Control Module | Input Voltage: 24V DC, Power: 35W, Dimensions: 180 x 230 x 50 mm |

| 330104-09-19-10-02-00 | Analog Output Module | Output Voltage: 0-10V, Power: 25W, Weight: 1.0 kg, Temperature Range: -20°C to +60°C |

| 330104-10-13-05-02-05 | High-Precision Control System | Input Voltage: 110V AC, Power: 40W, Dimensions: 190 x 250 x 60 mm |

| 330104-10-16-05-01-00 | Process Monitoring and Control Unit | Input Voltage: 220V AC, Power: 30W, Dimensions: 200 x 270 x 55 mm |

| 330104-10-16-10-02-00 | Advanced Signal Conditioning Module | Output Voltage: 0-5V, Power: 28W, Weight: 1.2 kg, Temperature Range: -10°C to +50°C |

FAQ (Frequently Asked Questions)

Q1: What is the primary use of the Bently Nevada 330104-13-20-50-02-00 proximity probe?

A1: The 330104-13-20-50-02-00 proximity probe is used for measuring vibration and shaft displacement in rotating machinery, providing data for predictive maintenance and fault detection.

Q2: What is the cable length of the Bently Nevada 330104-13-20-50-02-00?

A2: The probe comes with a 5.0-meter cable, which provides flexibility for various installation configurations.

Q3: What type of output does the 330104-13-20-50-02-00 provide?

A3: This proximity probe outputs an analog displacement signal, which is used to monitor changes in the vibration levels or shaft position of machinery.

Q4: What is the temperature range for this proximity probe?

A4: The 330104-13-20-50-02-00 operates within a temperature range of -40°C to +120°C, making it suitable for use in extreme industrial environments.

Q5: What industries typically use the Bently Nevada proximity probes?

A5: These probes are used in industries such as power generation, oil & gas, mining, manufacturing, and any application involving rotating machinery.

Q6: Can the 330104-13-20-50-02-00 be used for large machinery?

A6: Yes, the 8mm probe is ideal for large-scale machinery such as turbines, motors, and generators, where precise vibration monitoring is required.

Q7: How does the proximity probe help in predictive maintenance?

A7: The probe continuously monitors displacement and vibration, allowing for early detection of issues like misalignment, imbalances, or bearing wear, which helps prevent unexpected failures.

Q8: What is the mounting method for this probe?

A8: The 330104-13-20-50-02-00 proximity probe uses standard probe mounting, making it compatible with most Bently Nevada and other vibration monitoring systems.

Q9: How accurate is the measurement provided by this probe?

A9: The probe provides highly accurate measurements of displacement and vibration, ensuring real-time data for accurate diagnostics and condition monitoring.

Q10: Can the probe be used outdoors?

A10: The 330104-13-20-50-02-00 probe is designed for use in industrial environments, and can be used outdoors if properly protected from environmental elements.