ProductPRODUCT

Featured products

Contact Us

- Bently Nevada

- 330104-03-09-05-02-05

- 8mm Proximity Probe (Metric)

- USA

- 0.5 meter

- 0.162kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 256

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Bently Nevada 330104-03-09-05-02-05 8mm Proximity Probe (Metric)

Product Description

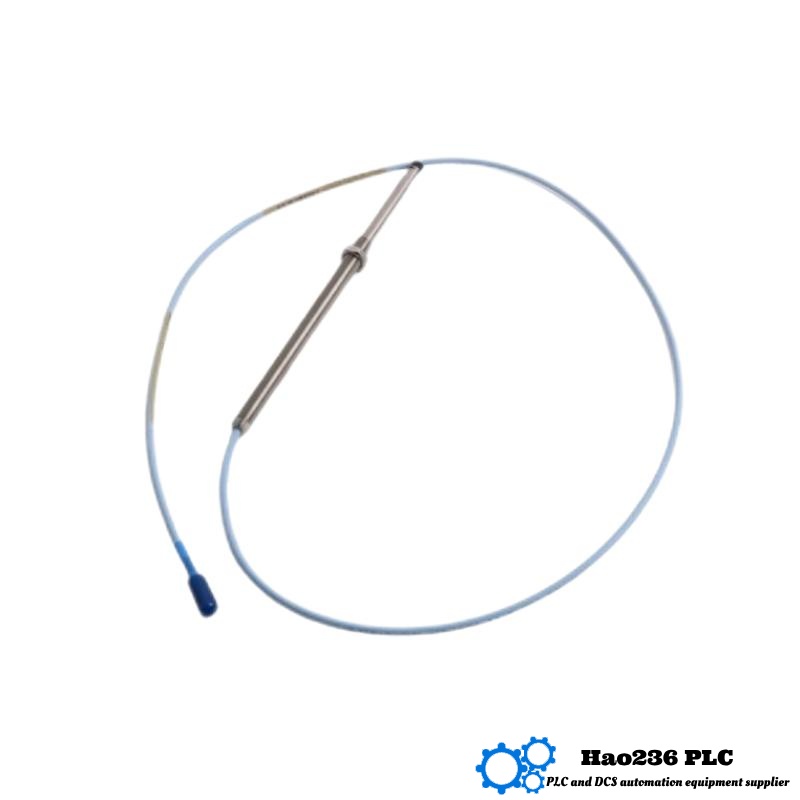

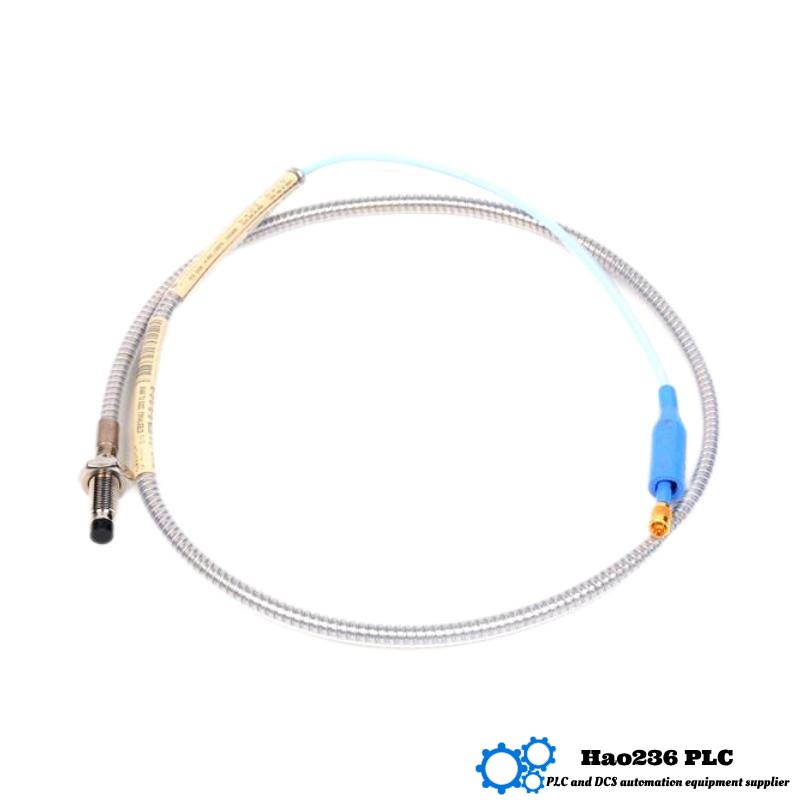

The Bently Nevada 330104-03-09-05-02-05 is a high-precision 8mm proximity probe designed to accurately measure shaft displacement and vibration in rotating machinery. Part of the 3300 XL Series, this probe is specifically engineered to provide continuous, non-contact monitoring for predictive maintenance and machinery protection.

By utilizing eddy-current sensing technology, the probe detects even the slightest variations in shaft position, allowing for early detection of potential failures such as misalignment, imbalance, and bearing wear. This non-contact design ensures longer operational life and higher reliability by reducing mechanical wear on the system.

With a total length of 0.5 meters and a weight of 0.162 kg, the 330104-03-09-05-02-05 is optimized for use in tight spaces while maintaining excellent durability in harsh industrial environments.

Product Applications

The 330104-03-09-05-02-05 proximity probe is ideal for a wide range of rotating machinery applications:

-

Turbines – Measures vibration and displacement in turbines to detect early signs of mechanical issues and prevent unplanned downtime.

-

Compressors – Continuously monitors compressor health, alerting operators to potential alignment issues, imbalance, or bearing failure.

-

Pumps – Helps identify cavitation, misalignment, or bearing problems before they lead to failure.

-

Motors – Ensures that electric motors are functioning within ideal operating parameters by measuring shaft displacement and vibration.

-

Gearboxes – Provides early detection of gear mesh issues and mechanical wear in gearbox assemblies.

Product Advantages

-

Precision and Accuracy: The 330104-03-09-05-02-05 offers high-precision measurements, providing accurate vibration and displacement data even in high-speed applications.

-

Non-contact Sensing: By using an eddy-current principle, the probe avoids physical contact with the machine, minimizing wear and ensuring longevity.

-

Durability in Harsh Environments: Designed to withstand extreme temperatures (up to 120°C) and high-vibration conditions, this probe delivers reliable performance even in the most demanding industrial settings.

-

Compact Design: The probe’s compact dimensions (0.5 meters in length and 0.162 kg in weight) make it easy to install and integrate into various monitoring systems without compromising performance.

-

Seamless Integration: Fully compatible with the 3300 XL Series monitoring systems, providing a complete solution for vibration and machinery condition monitoring.

Brand Information

Bently Nevada, a division of Baker Hughes, is one of the world’s leading manufacturers of machinery condition monitoring systems. With over 50 years of expertise in the field, Bently Nevada provides a wide range of sensors, systems, and solutions that help industries reduce downtime, extend asset life, and improve overall operational efficiency.

Series Information

The 3300 XL Series from Bently Nevada is a comprehensive suite of vibration monitoring equipment designed for both machinery protection and predictive maintenance. Known for its advanced performance and accuracy, the 3300 XL Series is used across a variety of industries including power generation, oil & gas, and manufacturing, offering solutions for monitoring rotating machinery such as pumps, turbines, motors, and compressors.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | 330104-03-09-05-02-05 |

| Probe Type | 8mm Proximity Probe |

| Total Length | 0.5 meter |

| Weight | 0.162 kg |

| Sensing Range | Nominal 8 mm |

| Frequency Response | 0 to 10 kHz |

| Temperature Range | Up to 120°C |

| Output | AC Signal |

| Mounting | Standard Threaded Mount |

| Cable Type | 3300 XL Series-compatible Cable |

Related Models from 3300 XL Series

| Model | Description | Sensing Type | Length | Weight (kg) |

|---|---|---|---|---|

| 330104-03-09-05-01-05 | 5mm proximity probe, compact design | Proximity (5mm) | 0.5 meter | 0.15 |

| 330104-03-09-05-03-05 | 10mm proximity probe, extended range | Proximity (10mm) | 0.5 meter | 0.18 |

| 330104-03-09-05-02-06 | 8mm probe with longer cable extension | Proximity (8mm) | 1 meter | 0.20 |

| 330104-03-09-05-02-04 | 8mm probe with enhanced protection | Proximity (8mm) | 0.5 meter | 0.17 |

| 330104-03-09-05-02-07 | 8mm probe for high-vibration areas | Proximity (8mm) | 0.5 meter | 0.18 |

Popular Models from Bently Nevada

| Model | Description | Sensing Type | Length | Weight (kg) |

|---|---|---|---|---|

| 3500/22 | Vibration monitoring module | Multi-sensor Input | N/A | 1.5 |

| 3300/20 | 4-20mA proximity sensor | Proximity | N/A | 0.5 |

| 3500/42M | Vibration and position monitoring | Vibration/Position | N/A | 2.2 |

| 3300/01 | Vibration monitoring for large machines | Vibration | N/A | 1.3 |

| 3300/03 | Displacement transducer for shaft monitoring | Displacement | N/A | 0.9 |

FAQ (Frequently Asked Questions)

Q1: What is the primary use of the 330104-03-09-05-02-05 proximity probe?

A1: This probe is used to monitor shaft displacement and vibration in rotating machinery, providing critical data for predictive maintenance and machinery protection.

Q2: Is this probe suitable for high-speed applications?

A2: Yes, with a frequency response range of 0 to 10 kHz, it is suitable for high-speed machinery.

Q3: What industries use the 330104-03-09-05-02-05 proximity probe?

A3: It is widely used in industries such as power generation, oil & gas, petrochemical, and manufacturing for monitoring turbines, compressors, pumps, and motors.

Q4: What is the sensing distance of the probe?

A4: The probe offers a nominal sensing distance of 8mm, providing precise displacement and vibration measurements.

Q5: How does the 330104-03-09-05-02-05 probe communicate with monitoring systems?

A5: The probe outputs an AC signal, which can be interpreted by the Bently Nevada 3300 XL monitoring system.

Q6: Is the probe easy to install?

A6: Yes, the probe features a standard threaded mount for easy and secure installation on machinery.

Q7: What is the maximum operating temperature of this probe?

A7: The probe is designed to withstand temperatures up to 120°C, ensuring reliable performance in high-temperature environments.

Q8: Can the probe be used with non-metallic shafts?

A8: No, the probe requires a conductive material like metal for accurate eddy-current measurements.

Q9: How long is the cable on the 330104-03-09-05-02-05?

A9: The total cable length is 0.5 meters, which is suitable for a variety of machinery setups.

Q10: What maintenance is required for the probe?

A10: The probe requires minimal maintenance but should be periodically checked for accuracy and calibrated as necessary to ensure optimal performance.