ProductPRODUCT

Featured products

Contact Us

- Bently Nevada

- 330104-00-16-10-02-00

- 8 mm Proximity Probe (Metric)

- USA

- 1.0 meter

- 0.323kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 151

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

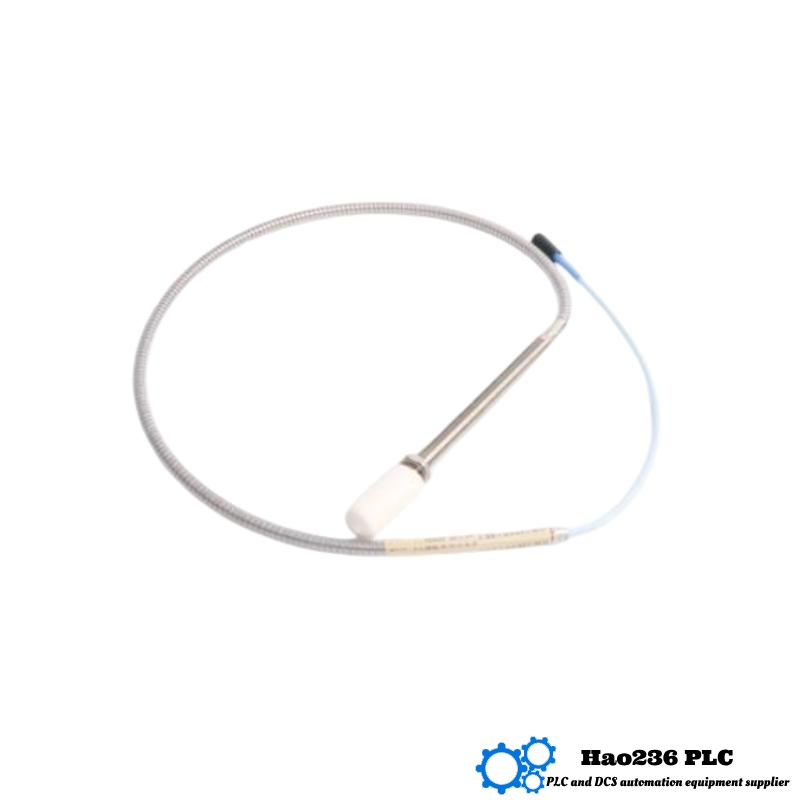

Bently Nevada 330104-00-16-10-02-00 8mm Proximity Probe (Metric)

Product Overview

The Bently Nevada 330104-00-16-10-02-00 proximity probe is part of the advanced 3300 XL series from Bently Nevada, a renowned brand in the field of vibration monitoring and asset condition monitoring. This 8mm probe is engineered to provide high-precision measurement of machine displacement, ensuring accurate detection of machinery malfunctions or performance degradation. The proximity probe is designed for use in a variety of applications, from rotating machinery to motors and pumps, where the early detection of faults is critical for maintaining operational efficiency and minimizing unplanned downtime.

The 330104-00-16-10-02-00 model is built with reliability in mind, offering robust construction for industrial environments. With a total length of 1 meter and a weight of 0.323kg, the probe is designed to be easily installed while offering superior performance under varying operating conditions.

Key Features

-

High Precision: Delivers accurate measurements of machine displacement, enhancing early detection of faults and performance deviations.

-

Durable Construction: Designed to withstand harsh industrial conditions, ensuring long-lasting reliability in tough environments.

-

Easy Integration: Compatible with Bently Nevada’s 3300 XL series, providing seamless integration into existing condition monitoring systems.

-

Compact Size: At 1 meter in length and weighing 0.323kg, the probe is lightweight and easy to install, saving valuable space in control panels and machinery setups.

-

Non-Contact Measurement: Offers non-contact measurement of shaft displacement, which avoids wear and tear typically associated with contact-based systems.

Product Applications

The Bently Nevada 330104-00-16-10-02-00 proximity probe is primarily used for monitoring and protecting machinery in various industries. Some of its key applications include:

-

Rotating Equipment: Used to measure shaft displacement and detect misalignments in rotating equipment like motors, turbines, and compressors.

-

Pumps: Ensures reliable performance by monitoring displacement in pumps, helping to identify any misalignment or wear.

-

Generators: Detects shaft vibration and displacement in generators, preventing failures and ensuring continuous power generation.

-

Compressors: Monitors compressor health by detecting deviations in displacement, helping to avoid catastrophic failures and extend equipment life.

-

Wind Turbines: Can be used to monitor displacement in wind turbine machinery, ensuring optimal performance and maintenance planning.

Advantages

-

Early Fault Detection: By continuously monitoring displacement, the probe ensures that any changes in machine condition are detected early, preventing unexpected failures.

-

Reduced Maintenance Costs: Accurate fault detection allows for predictive maintenance, reducing costly repairs and unplanned downtime.

-

Long-Term Durability: Built to withstand challenging industrial environments, the 330104-00-16-10-02-00 probe offers long-lasting, reliable performance in harsh conditions.

-

Enhanced Machine Performance: Ensures that equipment operates within its optimal performance parameters by identifying issues before they escalate into larger problems.

-

Seamless Integration: Easily integrates with Bently Nevada’s 3300 XL series, offering a complete monitoring solution.

Brand

-

Bently Nevada: Bently Nevada is a global leader in condition monitoring and vibration analysis, providing advanced solutions to help businesses improve asset reliability and reduce the risk of failure. With a focus on high-quality instrumentation and data analytics, Bently Nevada is trusted by industries worldwide for critical machine monitoring.

Series

-

3300 XL Series: The 3300 XL series from Bently Nevada is designed for high-precision condition monitoring, offering a range of sensors, probes, and systems that allow for continuous monitoring of machine health. These products are widely used in industries such as oil and gas, power generation, and manufacturing.

Product Specifications

| Parameter | Value |

|---|---|

| Model | 330104-00-16-10-02-00 |

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Probe Diameter | 8 mm |

| Operating Temperature | -40°C to 121°C |

| Sensitivity | High Precision |

| Mounting | Threaded Mounting |

| Connector Type | 5-pin, MIL-C-5015 |

| Signal Type | Linear Analog |

Related Models in the Bently Nevada 3300 XL Series

| Model | Total Length | Weight | Probe Diameter | Connector Type | Signal Type |

|---|---|---|---|---|---|

| 330104-00-16-10-01-00 | 1.0 meter | 0.315 kg | 8 mm | MIL-C-5015 | Linear Analog |

| 330104-00-16-10-02-01 | 1.2 meter | 0.350 kg | 8 mm | MIL-C-5015 | Linear Analog |

| 330104-00-16-10-03-00 | 1.5 meter | 0.380 kg | 8 mm | MIL-C-5015 | Linear Analog |

| 330104-00-16-10-02-02 | 1.0 meter | 0.325 kg | 8 mm | MIL-C-5015 | Linear Analog |

| 330104-00-16-10-02-03 | 2.0 meter | 0.400 kg | 8 mm | MIL-C-5015 | Linear Analog |

Other Popular Bently Nevada Models

| Model | Total Length | Weight | Probe Diameter | Connector Type | Signal Type |

|---|---|---|---|---|---|

| 330130-00-16-10-00-00 | 1.0 meter | 0.310 kg | 8 mm | MIL-C-5015 | Linear Analog |

| 330850-00-00-00-00-00 | 1.0 meter | 0.350 kg | 8 mm | MIL-C-5015 | Linear Analog |

| 330106-00-16-10-02-00 | 1.5 meter | 0.365 kg | 8 mm | MIL-C-5015 | Linear Analog |

| 330330-00-16-10-01-00 | 1.0 meter | 0.320 kg | 8 mm | MIL-C-5015 | Linear Analog |

| 330000-00-16-10-00-00 | 1.0 meter | 0.330 kg | 8 mm | MIL-C-5015 | Linear Analog |

FAQs

Q1: What is the main function of the Bently Nevada 330104-00-16-10-02-00 proximity probe?

A1: The probe is used to measure the displacement of rotating machinery, helping to detect faults such as misalignments, imbalance, and other operational issues.

Q2: How is the Bently Nevada 330104-00-16-10-02-00 probe mounted?

A2: The probe is mounted using a threaded connection, ensuring a secure fit in a variety of machinery applications.

Q3: What is the operating temperature range for this probe?

A3: The operating temperature range is -40°C to 121°C, making it suitable for use in a wide range of industrial environments.

Q4: Can the 330104-00-16-10-02-00 be used in hazardous environments?

A4: Yes, the Bently Nevada probes are built to withstand harsh industrial conditions, including exposure to high temperatures and vibrations.

Q5: What industries use the 330104-00-16-10-02-00 probe?

A5: It is commonly used in industries such as oil and gas, power generation, manufacturing, and any industry requiring vibration monitoring for rotating machinery.

Q6: What is the signal type produced by this probe?

A6: The probe produces a linear analog signal, which is used to monitor machine displacement.

Q7: How long is the total length of the probe?

A7: The total length of the probe is 1.0 meter.

Q8: What is the weight of the Bently Nevada 330104-00-16-10-02-00?

A8: The weight of the probe is 0.323 kg.

Q9: What is the diameter of the probe tip?

A9: The probe has an 8 mm diameter, suitable for a wide range of machinery monitoring applications.

Q10: How does the probe contribute to predictive maintenance?

A10: By accurately measuring displacement and detecting issues early, the probe helps prevent unexpected failures, reducing downtime and maintenance costs.