ProductPRODUCT

Featured products

Contact Us

- Bently Nevada

- 330104-00-06-10-02-00

- 8 mm Proximity Probe (Metric)

- USA

- 1.0 meter

- 0.323kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 191

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

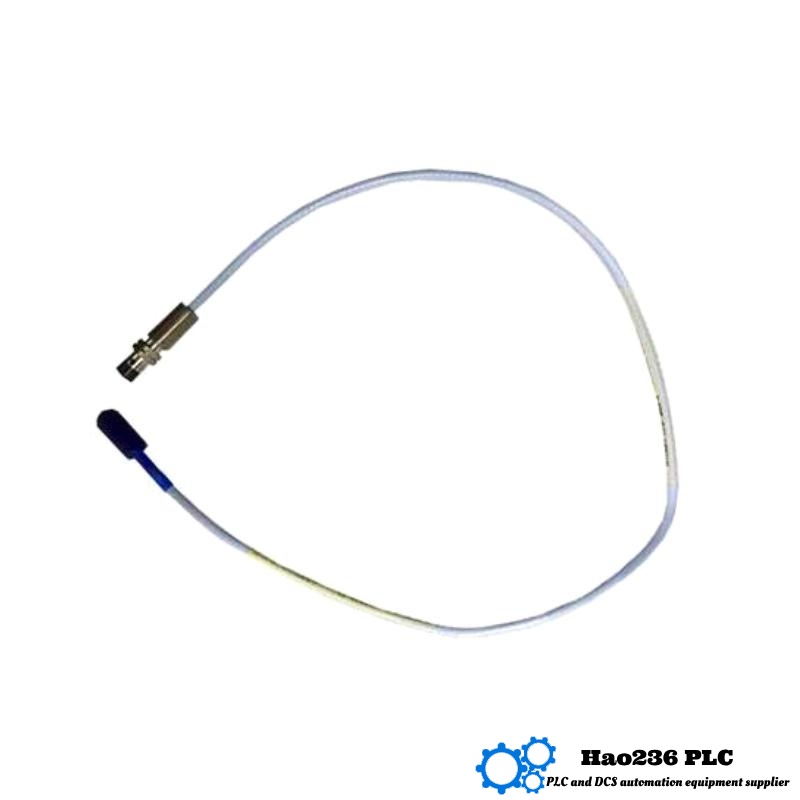

Bently Nevada 330104-00-06-10-02-00 8 mm Proximity Probe (Metric)

Product Introduction

The Bently Nevada 330104-00-06-10-02-00 is an 8 mm proximity probe from the 3300 XL series designed for high-precision monitoring of rotating machinery. This metric proximity probe plays a key role in vibration and position monitoring applications, offering real-time diagnostic data for predictive maintenance programs. Built to operate in the most demanding industrial environments, it is an essential tool for ensuring the reliability, efficiency, and health of critical rotating machinery.

This proximity probe measures axial displacement and vibration with high accuracy, providing vital insights that help prevent unplanned downtime and extend the life of machinery. With its 1.0-meter total length and 0.323 kg weight, it is engineered for ease of installation and consistent performance in a wide range of industrial applications.

Product Applications

-

Vibration Monitoring: Ideal for monitoring vibrations in turbines, motors, pumps, and compressors, helping detect mechanical faults at an early stage.

-

Shaft Position Monitoring: Provides precise measurements of shaft position and axial displacement to avoid misalignment and damage to critical equipment.

-

Condition Monitoring: Enables continuous condition monitoring of rotating machinery to optimize performance and minimize the risk of catastrophic failures.

-

Predictive Maintenance: Helps identify potential issues before they result in equipment failure, supporting efficient predictive maintenance strategies and minimizing downtime.

Product Advantages

-

High Precision: Offers accurate vibration and displacement measurements, essential for detecting early signs of equipment wear or misalignment.

-

Durability: Built to withstand harsh industrial environments, ensuring long-term reliability and performance in extreme conditions.

-

Ease of Installation: The 8 mm diameter design allows for easy installation and integration with standard machinery and monitoring systems.

-

Versatile: Suitable for a variety of rotating machinery, including turbines, compressors, motors, and more, making it a flexible solution across industries.

-

Real-Time Data: Provides real-time data to enable quick decision-making and proactive maintenance, improving equipment uptime and performance.

Brand

Bently Nevada is a global leader in condition monitoring and machinery protection. Known for its high-precision products, Bently Nevada specializes in offering reliable solutions that help industries safeguard their critical machinery and assets. The 3300 XL series represents the forefront of vibration and position monitoring technology, providing robust, accurate, and reliable performance in the most demanding environments.

Technical Specifications

| Parameter | Value |

|---|---|

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Probe Type | 8 mm proximity probe (metric) |

| Measurement Range | Vibration and displacement monitoring |

| Environmental Suitability | Designed for extreme industrial environments |

| Series | 3300 XL Series |

| Application | Vibration and position monitoring for rotating machinery |

Recommended Related Models

| Model | Description | Application | Weight |

|---|---|---|---|

| 330103-00-10-10-02-06 | 8 mm proximity probe (metric) | Vibration monitoring for rotating equipment | 0.323 kg |

| 330104-00-10-10-02-06 | 8 mm proximity probe (metric) | Monitoring for industrial machinery | 0.324 kg |

| 330103-00-10-10-02-08 | 8 mm proximity probe (metric) | Shaft position monitoring | 0.322 kg |

| 330104-00-10-10-02-07 | 8 mm proximity probe (metric) | Vibration diagnostics | 0.323 kg |

| 330103-00-10-10-02-09 | 8 mm proximity probe (metric) | High-speed machinery diagnostics | 0.321 kg |

Recommended Popular Models from Bently Nevada

| Model | Description | Application | Weight |

|---|---|---|---|

| 330103-00-10-10-02-05 | 8 mm proximity probe (metric) | Continuous monitoring for rotating equipment | 0.323 kg |

| 330104-00-10-10-02-07 | 8 mm proximity probe (metric) | Vibration diagnostics for compressors | 0.318 kg |

| 330103-00-10-10-02-04 | 8 mm proximity probe (metric) | Monitoring of rotating machinery in power plants | 0.324 kg |

| 330102-00-10-10-02-03 | 5 mm proximity probe (metric) | Precision vibration and position monitoring | 0.312 kg |

| 330102-00-10-10-02-08 | 5 mm proximity probe (metric) | Predictive maintenance for turbines | 0.310 kg |

FAQ

Q1: What is the primary function of the Bently Nevada 330104-00-06-10-02-00 proximity probe?

A1: The primary function of the probe is to measure vibration and shaft position in rotating machinery, providing real-time data for predictive maintenance and machine health monitoring.

Q2: What is the total length of this probe?

A2: The total length of the probe is 1.0 meter.

Q3: What is the weight of the 330104-00-06-10-02-00 probe?

A3: The probe weighs 0.323 kg.

Q4: Can this probe be used in extreme environments?

A4: Yes, the 330104-00-06-10-02-00 is designed to operate reliably in harsh industrial environments.

Q5: How accurate is the 330104-00-06-10-02-00 probe?

A5: This probe offers high-precision vibration and displacement measurements, ensuring accurate monitoring of machine health.

Q6: In what industries can this probe be used?

A6: The probe is used in power generation, oil and gas, chemical processing, and other industries that rely on rotating machinery.

Q7: What is the purpose of using a proximity probe like the 330104-00-06-10-02-00?

A7: The probe helps monitor machinery condition, detect faults early, and prevent unplanned downtime by providing real-time diagnostic data.

Q8: How is the probe installed?

A8: The 330104-00-06-10-02-00 probe is designed with a standard 8 mm diameter, making it easy to install in most industrial applications.

Q9: Can the 330104-00-06-10-02-00 probe be integrated with other Bently Nevada systems?

A9: Yes, this probe integrates seamlessly with Bently Nevada’s machinery health monitoring systems for continuous diagnostics.

Q10: What maintenance does the 330104-00-06-10-02-00 probe support?

A10: This probe supports predictive maintenance by providing continuous monitoring of machine conditions, helping detect mechanical issues early.