Product Overview

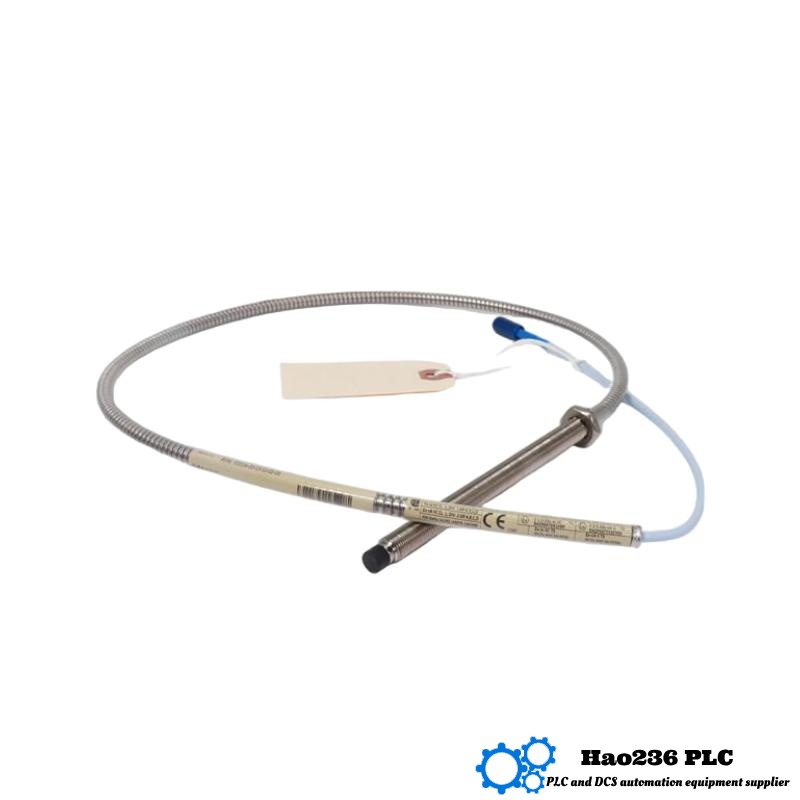

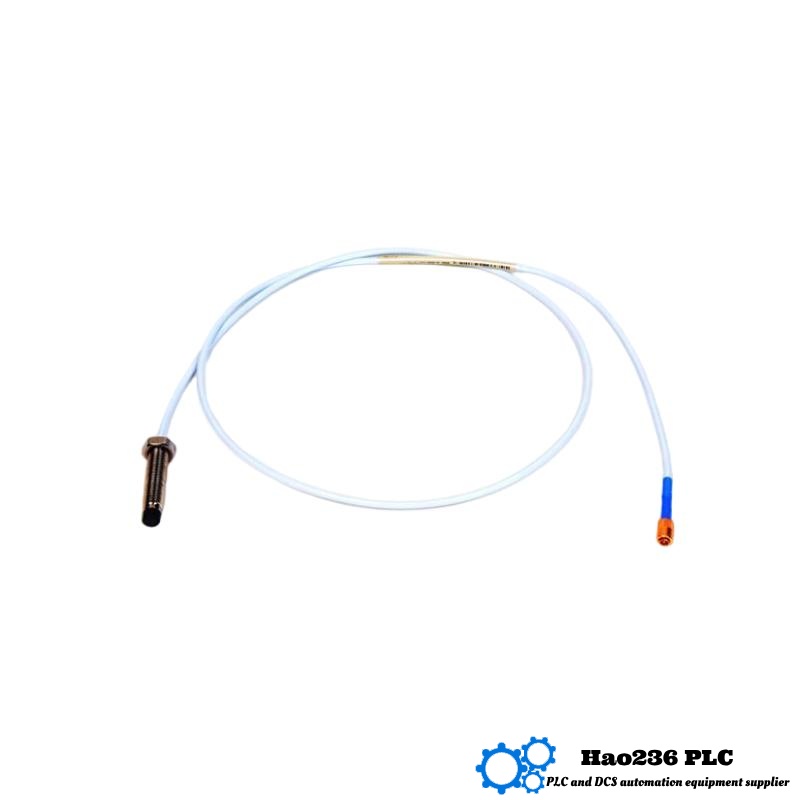

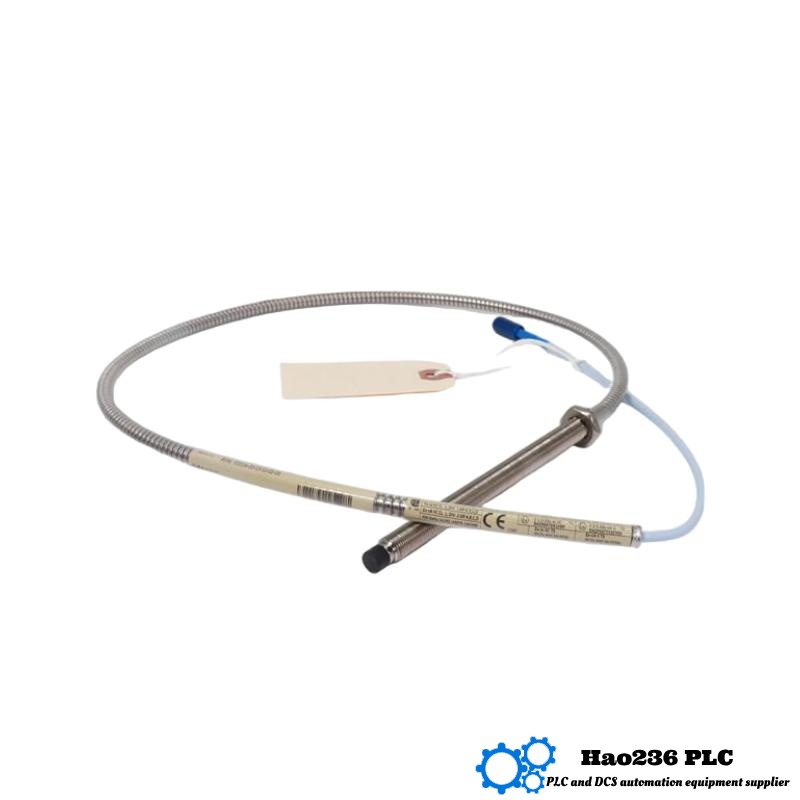

The Bently Nevada 330104-00-03-10-01-00 is an 8 mm proximity probe designed for precise and non-contact measurement of displacement and vibration in rotating machinery. As part of the 3300 XL Series, this probe offers unparalleled accuracy and durability, making it an ideal solution for continuous condition monitoring and predictive maintenance in industrial environments.

With a total system length of 1.0 meters, the probe is optimized for applications where moderate reach is required, providing flexibility in installation. It features high sensitivity and a wide frequency response, ensuring accurate data collection for real-time machine diagnostics.

This probe is built to endure harsh industrial conditions, including exposure to oil, moisture, and extreme temperatures. It integrates seamlessly with 3300 XL Proximitor Sensors, offering high-quality monitoring for turbines, motors, compressors, pumps, and other critical machinery.

Product Parameters

| Parameter |

Value |

| Model Number |

330104-00-03-10-01-00 |

| Probe Tip Diameter |

8 mm |

| Thread Type |

M10 x 1 (Metric) |

| Tip Material |

Stainless Steel |

| Total Length |

1.0 meters |

| Weight |

0.323 kg |

| Connector Type |

Miniature coaxial connector |

| Measurement Range |

2 mm nominal |

| Frequency Response |

DC to 10 kHz |

| Temperature Range |

-35°C to +177°C |

| Pressure Rating |

Suitable for industrial sealed environments |

| Insulation Resistance |

>10⁹ Ohms |

| Cable Sheath Material |

PFA-coated |

| Vibration Resistance |

50 g peak, 10–2000 Hz |

| Compatible System |

3300 XL Proximitor Sensors |

| Series |

3300 XL Series |

| Measurement Standard |

Metric |

Product Description

The 330104-00-03-10-01-00 proximity probe utilizes advanced eddy-current technology to measure shaft displacement and vibration in rotating equipment. This non-contact probe delivers high-precision measurements without causing mechanical wear or damage to the shaft.

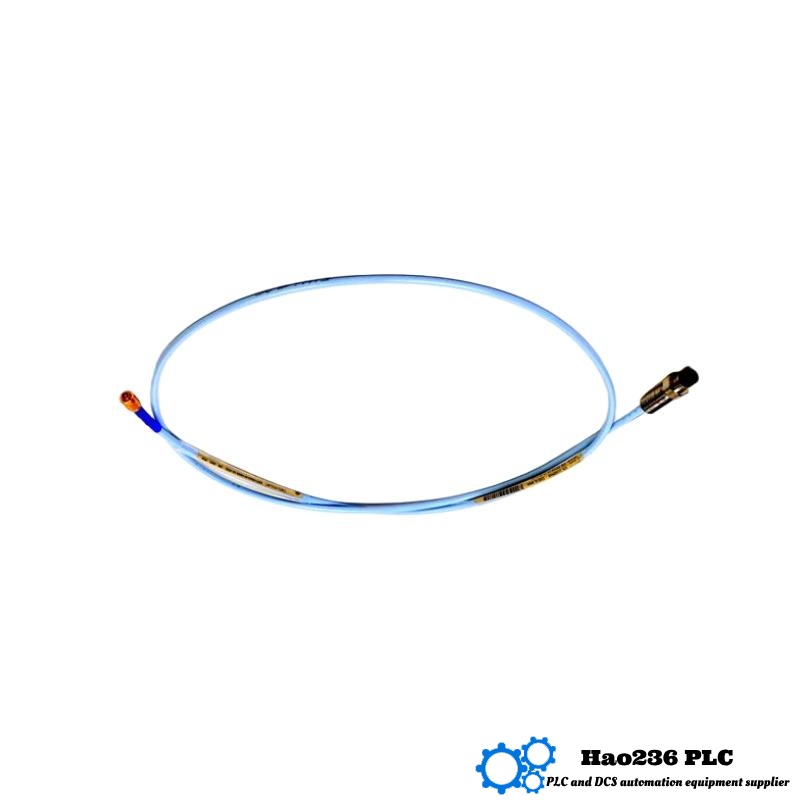

With its 1.0-meter total length, the probe offers a good balance between reach and compactness, making it suitable for medium to large machinery where precise monitoring is required. The stainless steel construction ensures excellent durability, while the PFA-coated cable provides additional resistance to harsh chemicals, moisture, and heat.

The probe is part of a comprehensive monitoring system when used with the 3300 XL Proximitor Sensor, allowing for reliable vibration and shaft displacement measurements. This system is critical for early fault detection and helps optimize machine performance by reducing downtime and maintenance costs.

Applications

-

Turbine Monitoring – For precise displacement and vibration measurement in steam, gas, and hydraulic turbines.

-

Pump Monitoring – Used to monitor shaft displacement and vibration in large industrial pumps.

-

Motor Protection – Ideal for continuous monitoring of electric motors, ensuring early detection of imbalance and misalignment.

-

Compressor Monitoring – Provides real-time data on compressor shaft conditions, helping to avoid expensive repairs and downtime.

-

Condition-Based Monitoring – Enables predictive maintenance by offering real-time displacement and vibration data.

Advantages

-

High Accuracy – Provides highly precise measurements of displacement and vibration, helping to detect potential issues early.

-

Durable Construction – Built with stainless steel and PFA-coated cable to withstand harsh industrial environments.

-

Versatile Length – The 1.0-meter system length makes it ideal for a wide range of industrial applications.

-

Reliable Performance – Offers seamless integration with 3300 XL Proximitor Sensors, ensuring consistent and accurate monitoring.

-

Cost-Effective Maintenance – By detecting problems early, the probe helps reduce unplanned downtime and lowers maintenance costs.

Brand

Bently Nevada – Bently Nevada is an industry leader in machinery protection, vibration analysis, and condition monitoring systems. Their products are known for their accuracy, durability, and reliability, making them essential for optimizing the performance and safety of critical industrial machinery.

Product Series

3300 XL Series – The 3300 XL Series is a comprehensive range of high-precision proximity probes and sensors designed for continuous condition monitoring. These systems are ideal for monitoring rotating machinery and are built to perform in even the harshest industrial environments. Known for their long service life and reliability, the 3300 XL Series is widely used in turbines, compressors, pumps, and motors.

Recommended Models from the 3300 XL Series

| Model |

Description |

System Length |

Weight |

| 330103-00-10-10-02-00 |

Standard 8 mm probe with 1.0-meter system length |

1.0 meter |

0.290 kg |

| 330103-00-15-10-02-00 |

8 mm probe for medium-length applications (1.5 meters) |

1.5 meters |

0.330 kg |

| 330103-00-25-10-02-00 |

8 mm probe with long system length (3.0 meters) |

3.0 meters |

0.400 kg |

| 330103-00-35-10-02-00 |

Long 8 mm probe for remote sensing applications |

5.0 meters |

0.450 kg |

| 330104-00-50-10-02-00 |

Extended 8 mm probe with flexible installation |

10.0 meters |

0.600 kg |

Popular Models from the Bently Nevada Portfolio

| Model |

Description |

System Length |

Weight |

| 330103-10-14-10-02-CN |

8 mm probe, 1.4 m probe + 10 m extension, China version |

11.4 meters |

0.455 kg |

| 330103-10-19-05-02-CN |

8 mm probe, 1.9 m probe + 5 m extension, CN market configuration |

6.9 meters |

0.420 kg |

| 330103-10-20-05-02-CN |

8 mm probe, 2.0 m probe + 5 m extension, CN-specific model |

7.0 meters |

0.425 kg |

| 330103-10-14-05-02-CN |

8 mm probe, 1.4 m probe + 5 m extension, compact CN variant |

6.4 meters |

0.410 kg |

| 330103-10-18-10-02-CN |

8 mm probe, 1.8 m probe + 10 m extension, extended range CN version |

11.8 meters |

0.460 kg |