ProductPRODUCT

Featured products

Contact Us

- Bently Nevada

- 330103-10-20-10-02-00

- 8 mm Proximity Probe (Metric)

- USA

- 1.0 meter

- 0.323kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 217

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

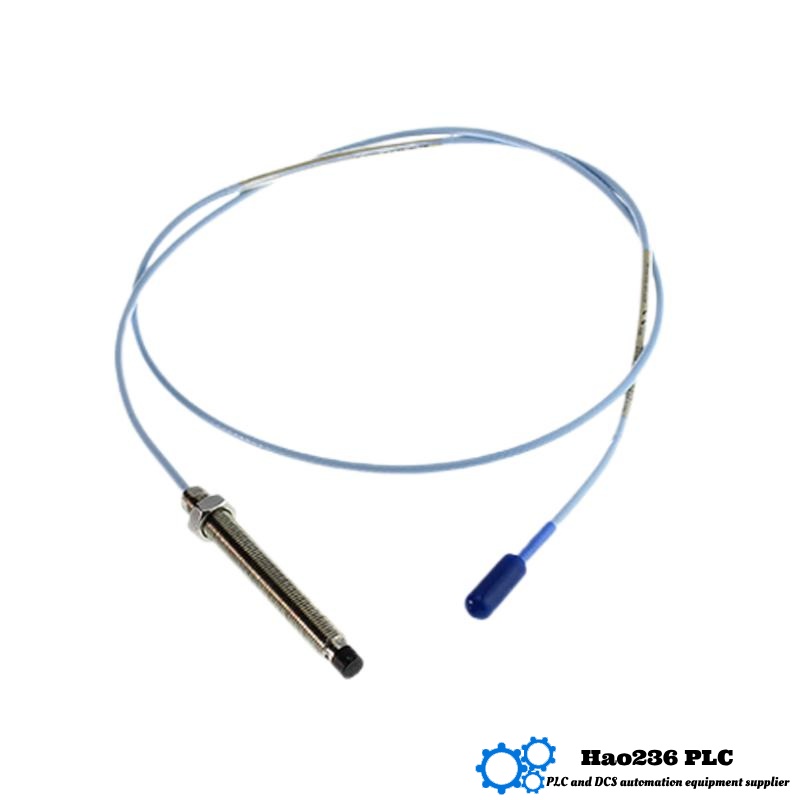

Bently Nevada 330103-10-20-10-02-00 8 mm Proximity Probe (Metric)

Product Introduction

The Bently Nevada 330103-10-20-10-02-00 is an 8 mm proximity probe from the 3300 XL series that is designed to provide highly accurate vibration and position monitoring for rotating machinery. This probe is an essential tool for condition monitoring, as it helps to detect early signs of misalignment, imbalance, and wear in critical components such as turbines, motors, and pumps. By detecting these issues early, the probe helps reduce the risk of catastrophic failure and prevents costly downtime.

Built with advanced inductive sensing technology, the 330103-10-20-10-02-00 probe ensures reliable performance and is engineered to withstand harsh industrial environments. It is ideal for use in industries like power generation, oil and gas, and manufacturing where continuous monitoring of rotating machinery is critical for operational safety and reliability.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | Bently Nevada 330103-10-20-10-02-00 |

| Type | 8 mm Proximity Probe (Metric) |

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Measuring Range | ±0.5 mm |

| Output Type | AC Inductive Output |

| Probe Diameter | 8 mm |

| Probe Material | Stainless Steel |

| Operating Temperature | –40°C to +120°C |

| Cable Length | 1 meter |

| Mounting Type | Threaded Mount |

| Application Compatibility | Compatible with Bently Nevada 3300 XL Series |

Product Applications

The Bently Nevada 330103-10-20-10-02-00 proximity probe is widely used in various applications within the field of vibration monitoring. Some of its key applications include:

-

Vibration Monitoring: The probe is used to measure vibrations in rotating machinery such as motors, turbines, compressors, and pumps. It helps identify issues such as imbalance and misalignment, ensuring smooth operation.

-

Position Monitoring: This probe is highly effective in monitoring the position of rotating components, such as shafts and bearings, to ensure proper alignment and prevent wear.

-

Condition Monitoring: The proximity probe continuously checks for changes in machinery health, detecting faults before they lead to system failure.

-

Preventive Maintenance: The data from this probe allows for the timely scheduling of maintenance, avoiding unexpected machinery failures and extending the lifespan of critical components.

-

Critical Machinery Protection: The 330103-10-20-10-02-00 probe provides protection for mission-critical assets by offering real-time data on machinery health.

Product Advantages

-

High Accuracy: This proximity probe is designed to offer high-precision measurements, ensuring accurate monitoring of machinery vibrations and positions.

-

Durable Construction: Made from stainless steel, the probe is built to withstand tough industrial conditions, ensuring long-term reliability.

-

Easy Integration: It is fully compatible with the 3300 XL series from Bently Nevada, ensuring seamless integration with other vibration monitoring systems.

-

Wide Operating Temperature Range: The probe is engineered to operate in extreme temperatures, from –40°C to +120°C, making it suitable for a wide range of environments.

-

Prevents Unexpected Failures: By continuously monitoring machinery health, the probe detects issues early, allowing for prompt corrective actions and preventing unplanned downtime.

-

Cost-Effective: Early detection of potential failures helps reduce repair costs and prolong the life of critical machinery.

-

Real-Time Monitoring: The probe offers continuous, real-time monitoring, enabling quick responses to any operational issues.

-

Enhanced Uptime: By reducing the risk of catastrophic breakdowns, the probe ensures higher operational uptime, contributing to overall productivity.

Brand: Bently Nevada

Bently Nevada, a division of Baker Hughes, is a renowned manufacturer of condition monitoring systems. The company specializes in providing advanced technology for monitoring the health of critical industrial assets. The 3300 XL series is one of the most trusted names in vibration monitoring, known for its accuracy, reliability, and ability to seamlessly integrate with other monitoring systems.

Recommended Models from the 3300 XL Series

Here are five other models from the 3300 XL series or related Bently Nevada products that can be used in similar applications:

| Model | Type | Key Features |

|---|---|---|

| 330103-10-20-10-02-05 | Proximity Probe (8 mm) | High-precision, designed for rotating machinery. |

| 330104-10-14-10-02-05 | Proximity Probe (8 mm) | Enhanced performance in vibration monitoring. |

| 330105-10-14-10-02-00 | Vibration Probe | Used for continuous monitoring of machinery health. |

| 330003-10-14-10-02-05 | 8 mm Probe Assembly | Designed for reliable vibration monitoring. |

| 330102-10-14-10-02-00 | Proximity Probe (8 mm) | Compact design for easy installation in critical machinery. |

Recommended Bently Nevada Popular Models

Here are five other popular Bently Nevada products that are highly regarded in the industry:

| Model | Type | Key Features |

|---|---|---|

| 330500-04-01-10-02-00 | Vibration Monitoring System | Complete solution for vibration monitoring. |

| 330101-10-14-10-02-05 | Proximity Probe (8 mm) | Precise, long-lasting performance for vibration analysis. |

| 330400-10-14-10-02-05 | Vibration Sensor | Used for comprehensive machinery monitoring. |

| 330301-10-14-10-02-05 | Proximity Probe (8 mm) | Ideal for critical industrial systems. |

| 330700-10-14-10-02-00 | Vibration Probe | High-performance probe for accurate readings. |

FAQ (Frequently Asked Questions)

-

Q: What is the purpose of the Bently Nevada 330103-10-20-10-02-00 proximity probe?

A: The probe is designed to monitor the vibration and position of rotating machinery, providing early warning of potential issues like misalignment or imbalance. -

Q: What is the measuring range of the 330103-10-20-10-02-00 probe?

A: The measuring range is ±0.5 mm. -

Q: What is the total length of the probe?

A: The total length of the probe is 1.0 meter. -

Q: How much does the Bently Nevada 330103-10-20-10-02-00 probe weigh?

A: The probe weighs 0.323 kg. -

Q: What type of output does the probe use?

A: The probe uses an AC inductive output to measure vibration and position. -

Q: What is the operating temperature range of this probe?

A: The probe operates in temperatures from –40°C to +120°C. -

Q: Is the probe easy to integrate with other systems?

A: Yes, the probe is fully compatible with the 3300 XL series and other Bently Nevada products. -

Q: How is the probe mounted?

A: The probe is mounted using a threaded design, making installation straightforward. -

Q: Can the probe be used in harsh environments?

A: Yes, the probe is made of durable stainless steel and can withstand extreme industrial conditions. -

Q: What machinery can the probe monitor?

A: The probe is used to monitor rotating machinery such as turbines, motors, and compressors.