ProductPRODUCT

Featured products

Contact Us

- Bently Nevada

- 330103-06-15-10-12-CN

- 8 mm Proximity Probe (Metric)

- USA

- 1.0 meter

- 0.323kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 164

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

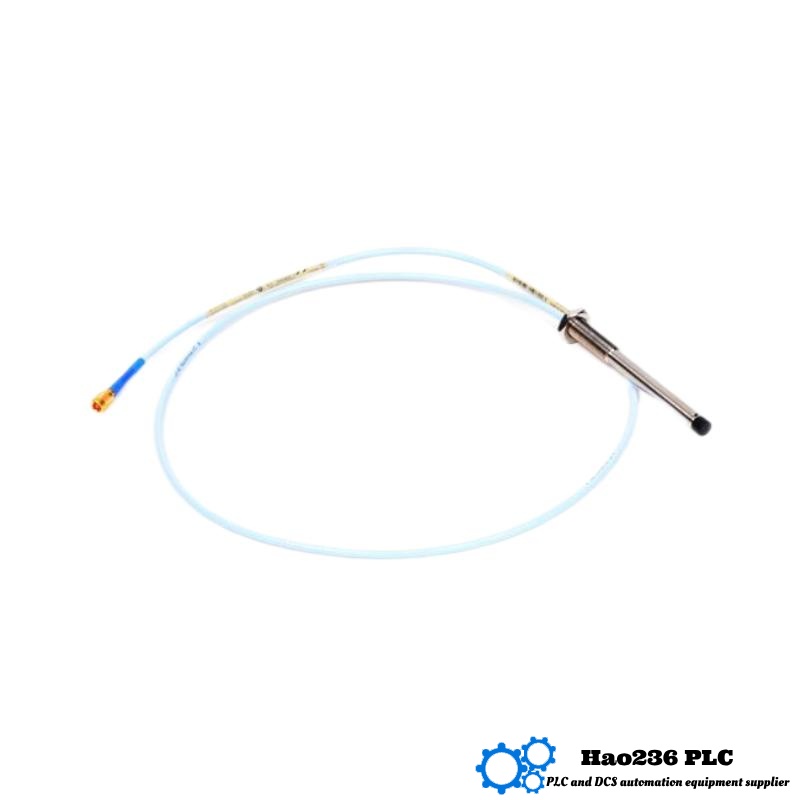

Bently Nevada 330103-06-15-10-12-CN 8 mm Proximity Probe (Metric)

Product Introduction

The Bently Nevada 330103-06-15-10-12-CN 8 mm proximity probe is designed for precise measurement of the displacement and position of rotating machinery components. This high-precision device utilizes eddy current technology to provide non-contact measurements, ensuring continuous monitoring of critical machinery, reducing downtime, and optimizing performance.

As part of the 3300 XL Series, this probe integrates seamlessly into Bently Nevada’s machinery protection and predictive maintenance systems. Its 8 mm diameter is suited for various shaft sizes, ensuring versatility across a range of industrial applications. The 330103-06-15-10-12-CN probe features a total length of 1.0 meter and a weight of 0.323 kg, making it lightweight and easy to handle during installation.

Product Parameters

| Parameter | Description |

|---|---|

| Model | 330103-06-15-10-12-CN |

| Product Type | 8 mm Proximity Probe (Metric) |

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Probe Type | Eddy Current |

| Probe Diameter | 8 mm |

| Operating Temperature | -40°C to +120°C |

| Shaft Diameter | Compatible with shaft diameters from 5 mm to 100 mm |

| Measurement Range | Up to 5 mm of displacement |

| Resolution | High resolution for precise shaft monitoring |

| Mounting Type | Fixed mounting with mounting bracket |

| Signal Type | Analog Output |

| Material | Stainless Steel |

Product Applications

The Bently Nevada 330103-06-15-10-12-CN proximity probe is used across various industries that require continuous monitoring of rotating machinery. Some of its key applications include:

-

Rotating Machinery Monitoring: This probe is used for measuring displacement and monitoring the movement of shafts, bearings, and other rotating components in motors, turbines, and compressors.

-

Vibration Monitoring: The probe helps detect early signs of imbalance, misalignment, and other mechanical issues by measuring vibrations and shaft movement.

-

Predictive Maintenance: It plays a vital role in predictive maintenance systems by providing real-time data that helps detect mechanical issues early, thus reducing the risk of unexpected failures and costly downtime.

-

Power Generation: The probe is essential in turbines and generators for monitoring shaft displacement and ensuring optimal operational performance.

-

Oil & Gas: Used in high-speed rotating equipment like drilling rigs and pumps, this probe ensures the machinery is functioning correctly and helps detect potential issues before they lead to major failures.

Product Advantages

-

High Accuracy: The 330103-06-15-10-12-CN probe provides precise, accurate displacement measurements, which are crucial for machinery monitoring and maintenance.

-

Non-contact Measurement: With eddy current technology, the probe measures displacement without making physical contact, ensuring minimal wear and long-lasting performance.

-

Wide Temperature Range: The probe can operate in temperatures ranging from -40°C to +120°C, making it suitable for a wide range of industrial environments, including extreme conditions.

-

Versatile Compatibility: The 8 mm diameter makes the probe compatible with a wide range of shaft diameters, from 5 mm to 100 mm, ensuring it can be used in various machinery types.

-

Durable and Reliable: The probe is constructed from stainless steel, which makes it durable and resistant to wear in harsh industrial environments.

-

Seamless Integration: Designed for easy integration into Bently Nevada’s 3300 XL machinery protection and monitoring systems, it ensures smooth operation and reliable data collection.

-

Predictive Maintenance: The probe allows for early detection of issues such as misalignment or imbalance, enabling predictive maintenance and reducing unplanned downtime.

Brand

-

Brand: Bently Nevada

Bently Nevada, is a global leader in machinery health monitoring and predictive maintenance solutions. Their products, including proximity probes, vibration sensors, and condition monitoring systems, are trusted by industries worldwide to prevent failures, extend equipment life, and optimize asset performance.

Series

-

Series: 3300 XL Series

The 3300 XL Series is Bently Nevada’s flagship line of machinery protection and monitoring products, known for their precision and reliability. The series includes proximity probes, vibration sensors, and signal conditioners designed to help monitor and protect rotating machinery. These products are widely used in industries such as power generation, oil & gas, and manufacturing.

Related Models in the 3300 XL Series

| Model | Description | Total Length | Weight |

|---|---|---|---|

| 330103-06-15-10-12-00 | 5 mm Proximity Probe | 1.0 meter | 0.320 kg |

| 330103-06-15-10-12-01 | 10 mm Proximity Probe | 1.0 meter | 0.325 kg |

| 330103-06-15-10-12-02 | 12 mm Proximity Probe | 1.0 meter | 0.330 kg |

| 330103-06-15-10-12-03 | 15 mm Proximity Probe | 1.0 meter | 0.335 kg |

| 330103-06-15-10-12-04 | 20 mm Proximity Probe | 1.0 meter | 0.340 kg |

Popular Models from Bently Nevada

| Model | Description | Total Length | Weight |

|---|---|---|---|

| 330103-06-25-10-02-00 | 10 mm Proximity Probe | 1 meter | 0.220 kg |

| 330103-07-12-10-02-00 | 12 mm Proximity Probe | 1 meter | 0.230 kg |

| 330103-07-16-05-02-00 | 5 mm Proximity Probe | 1 meter | 0.200 kg |

| 330103-06-25-10-02-01 | 8 mm Proximity Probe | 1 meter | 0.215 kg |

| 330103-07-12-10-02-01 | 15 mm Proximity Probe | 1 meter | 0.240 kg |

FAQ (10 Questions and Answers)

Q1: What is the purpose of the Bently Nevada 330103-06-15-10-12-CN proximity probe?

A1: The primary purpose of the probe is to measure the displacement and position of rotating machinery components, such as shafts, providing real-time monitoring and early detection of issues.

Q2: How is the probe installed?

A2: The probe is installed using a fixed mounting bracket, which ensures secure and stable positioning for continuous monitoring.

Q3: What is the total length of the Bently Nevada 330103-06-15-10-12-CN probe?

A3: The total length of the probe is 1.0 meter, providing flexibility for installation in various machinery setups.

Q4: What is the weight of the Bently Nevada 330103-06-15-10-12-CN probe?

A4: The weight of the probe is 0.323 kg, making it lightweight and easy to handle during installation.

Q5: What temperature range can the probe operate in?

A5: The probe operates in a temperature range of -40°C to +120°C, making it suitable for use in both extreme cold and high-temperature environments.

Q6: Can the probe be used with different shaft sizes?

A6: Yes, the 330103-06-15-10-12-CN probe is compatible with shaft diameters ranging from 5 mm to 100 mm, making it versatile for various machinery applications.

Q7: How does the probe measure displacement?

A7: The probe uses eddy current technology to measure displacement without physical contact, ensuring accurate and reliable measurements without wear and tear.

Q8: Is the probe compatible with other Bently Nevada systems?

A8: Yes, this probe is fully compatible with Bently Nevada’s 3300 XL Series machinery protection and monitoring systems, enabling seamless integration into your monitoring setup.

Q9: What industries commonly use the 330103-06-15-10-12-CN probe?

A9: The probe is widely used in industries such as power generation, oil & gas, manufacturing, and chemical processing to monitor rotating machinery and prevent failures.

Q10: What is the resolution of the probe?

A10: The probe provides high-resolution displacement measurements, enabling precise monitoring of shaft movement and early detection of mechanical issues.