ProductPRODUCT

Featured products

Contact Us

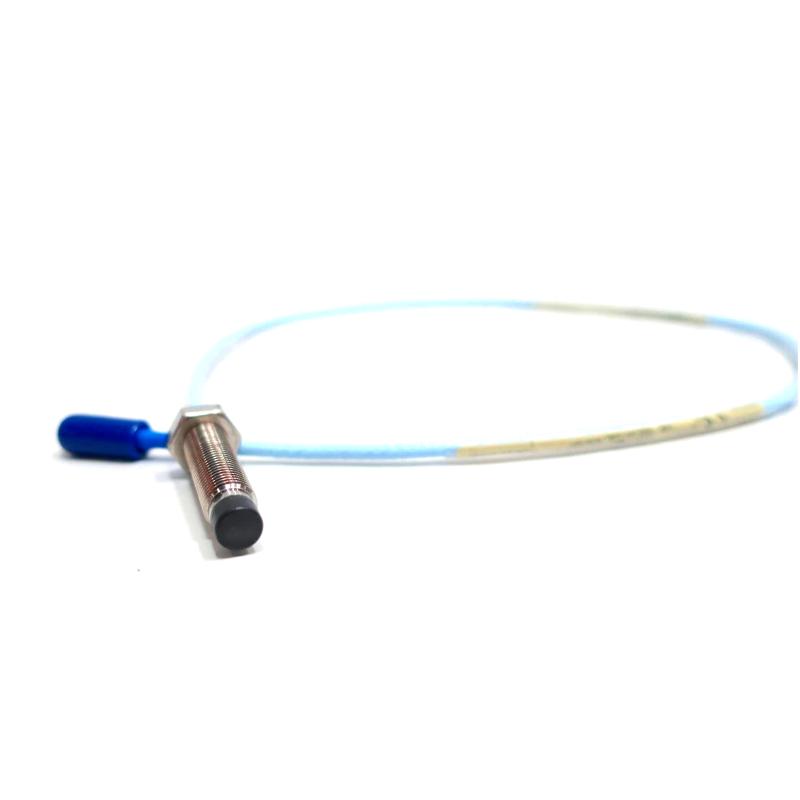

- Bently Nevada

- 330103-00-04-10-02-CN

- 3300 XL 8 mm Proximity Probe

- USA

- 145 x 120 x 75 mm

- 0.58kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 44

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Bently Nevada 330103-00-04-10-02-CN Product Overview

Product Introduction:

The Bently Nevada 330103-00-04-10-02-CN is a high-performance vibration and displacement monitoring sensor designed for use in industrial environments where rotating machinery requires precise condition monitoring. As part of the Bently Nevada 3300 Series, this product is engineered to provide real-time feedback on vibration and displacement measurements, helping detect mechanical faults early and preventing unplanned downtime. It plays a crucial role in predictive maintenance programs, reducing maintenance costs and increasing operational efficiency.

This specific model, the 330103-00-04-10-02-CN, is designed to be compatible with a wide range of industrial machinery, including turbines, motors, pumps, and compressors. It is ideal for environments where high-accuracy vibration monitoring is essential, and it offers features that are necessary for maintaining the health of critical rotating equipment.

Key Features:

-

Real-Time Monitoring: Provides continuous feedback on vibration and displacement, allowing for early detection of potential failures.

-

Accurate Measurements: Delivers highly precise readings to identify issues like imbalance, misalignment, or bearing wear.

-

Rugged and Durable: Built to withstand extreme industrial conditions, such as high levels of vibration, temperature fluctuations, and harsh environments.

-

Predictive Maintenance: By identifying issues before they escalate, the sensor helps schedule maintenance proactively, reducing unexpected downtime.

-

Flexible Integration: The device can easily integrate with existing monitoring systems, providing valuable data without significant disruption.

Applications:

-

Turbines: Monitors the health of turbines by detecting early signs of wear, imbalance, or misalignment.

-

Motors: Used to measure vibration levels and displacement in motors, ensuring smooth operation and identifying potential faults.

-

Compressors: Tracks the condition of compressors to prevent operational failures and maintain efficiency.

-

Pumps: Continuously monitors pumps, detecting issues like imbalance and misalignment to improve performance and reliability.

-

Rotating Equipment: Suitable for monitoring any type of rotating machinery in various industrial sectors, including manufacturing, energy, and petrochemicals.

Product Advantages:

-

Early Fault Detection: The device’s real-time monitoring allows for early detection of mechanical faults, preventing catastrophic failures.

-

High Durability: It is designed to withstand harsh industrial conditions, making it ideal for extreme temperature, humidity, and vibration environments.

-

Cost Efficiency: Reduces maintenance costs by helping avoid unnecessary repairs and downtime through predictive maintenance.

-

Improved Operational Reliability: Continuous monitoring ensures that machinery is always operating optimally, leading to better overall system performance.

-

Simple Integration: The device is compatible with most existing monitoring systems, making it easy to implement and use without extensive modification.

Brand and Series Information:

-

Brand: Bently Nevada

-

Series: 3300 Series

Detailed Specifications (Bently Nevada 330103-00-04-10-02-CN)

| Parameter | Value |

|---|---|

| Model Number | 330103-00-04-10-02-CN |

| Measurement Type | Vibration, Displacement |

| Accuracy | ±0.1% of Full Scale |

| Operating Temperature | -40°C to 85°C |

| Storage Temperature | -40°C to 85°C |

| Supply Voltage | 18-32 V DC |

| Current Consumption | 60 mA max |

| Output Type | 4-20 mA, RS-485 |

| Weight | 0.58 kg |

| Dimensions (L x W x H) | 145 x 120 x 75 mm |

| Vibration Monitoring Range | 0.01 to 1000 mm/s |

| Humidity | 5% to 95% non-condensing |

| Mounting Type | Bolt-on, flush mount |

Recommended Related Models (Same Series or Similar)

| Model | Measurement Type | Accuracy | Weight | Dimensions (LxWxH) |

|---|---|---|---|---|

| 330104-00-04-10-01-00 | Vibration, Temperature | ±0.1% of Full Scale | 0.49 kg | 118 x 100 x 50 mm |

| 330105-00-04-10-01-00 | Vibration, Displacement | ±0.1% of Full Scale | 0.52 kg | 122 x 105 x 60 mm |

| 330106-00-04-10-01-00 | Vibration | ±0.1% of Full Scale | 0.54 kg | 125 x 110 x 55 mm |

| 330107-00-04-10-01-00 | Vibration, Displacement | ±0.2% of Full Scale | 0.56 kg | 130 x 115 x 65 mm |

| 330108-00-04-10-01-00 | Vibration, Temperature | ±0.1% of Full Scale | 0.53 kg | 120 x 110 x 60 mm |

Popular Models from Bently Nevada

| Model | Measurement Type | Accuracy | Weight | Dimensions (LxWxH) |

|---|---|---|---|---|

| 330202-00-04-10-01-00 | Vibration | ±0.1% of Full Scale | 0.61 kg | 130 x 110 x 60 mm |

| 330301-00-04-10-01-00 | Vibration, Displacement | ±0.1% of Full Scale | 0.59 kg | 135 x 115 x 55 mm |

| 330502-00-04-10-01-00 | Vibration, Temperature | ±0.05% of Full Scale | 0.70 kg | 140 x 120 x 70 mm |

| 330601-00-04-10-01-00 | Vibration | ±0.2% of Full Scale | 0.64 kg | 130 x 105 x 60 mm |

| 330702-00-04-10-01-00 | Vibration, Displacement | ±0.2% of Full Scale | 0.58 kg | 125 x 110 x 65 mm |

Frequently Asked Questions (FAQ)

Q1: What is the main function of the Bently Nevada 330103-00-04-10-02-CN?

A1: The device monitors vibration and displacement in rotating machinery. It detects early signs of mechanical issues, helping prevent unexpected breakdowns and improving maintenance planning.

Q2: What types of equipment can the 330103-00-04-10-02-CN monitor?

A2: The device can monitor various types of rotating machinery, including turbines, motors, compressors, pumps, and other critical equipment.

Q3: What is the accuracy of the vibration measurements?

A3: The Bently Nevada 330103-00-04-10-02-CN offers an accuracy of ±0.1% of full scale, ensuring precise measurements for early fault detection.

Q4: Can this device operate in extreme environmental conditions?

A4: Yes, the device is designed to operate in harsh environments, with an operating temperature range from -40°C to 85°C and non-condensing humidity levels of 5% to 95%.

Q5: What communication options does the device support?

A5: The device supports 4-20 mA output and RS-485 communication, allowing easy integration with other monitoring systems.

Q6: How is the device mounted?

A6: The 330103-00-04-10-02-CN is mounted using a bolt-on, flush-mount system, ensuring secure and reliable installation.

Q7: What power supply is required for the device?

A7: The device requires a DC supply voltage of 18-32 V, with a maximum current consumption of 60 mA.

Q8: How does this product contribute to predictive maintenance?

A8: By continuously monitoring vibration and displacement, the device helps detect early signs of potential failures, enabling maintenance teams to act before problems lead to significant damage.

Q9: How does this model help improve machinery reliability?

A9: The device provides continuous, real-time feedback on equipment condition, allowing operators to address potential issues before they affect equipment performance or cause failure.

Q10: Is the device compatible with other Bently Nevada monitoring systems?

A10: Yes, the 330103-00-04-10-02-CN is designed to easily integrate with other Bently Nevada products, allowing for seamless monitoring and system expansion.