ProductPRODUCT

Featured products

Contact Us

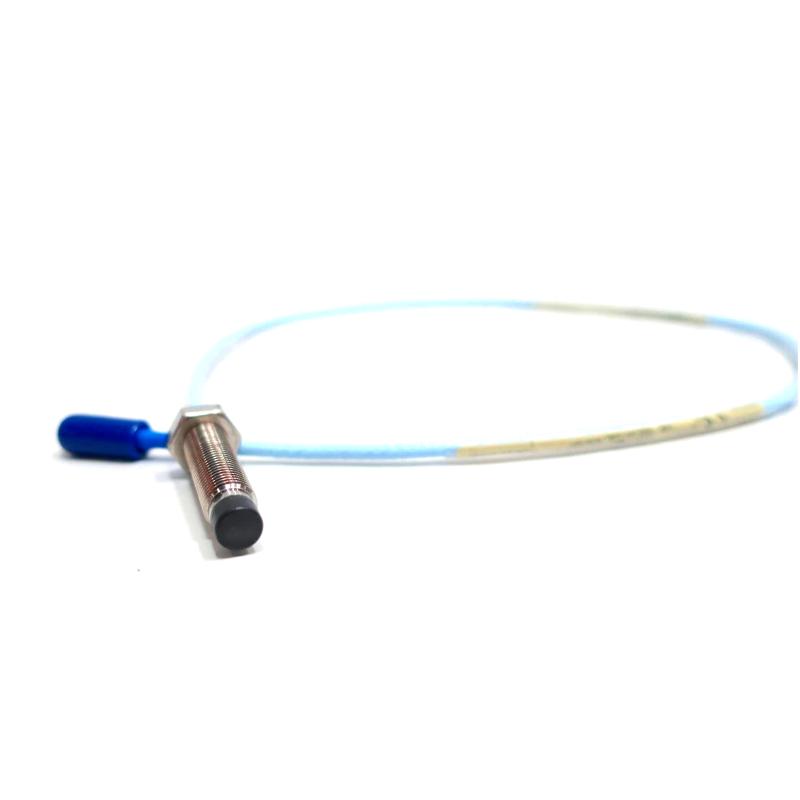

- Bently Nevada

- 330102-00-40-10-02-00

- 3300 XL 8 mm Proximity Probe

- USA

- 150 mm x 110 mm x 95 mm

- 1.8kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 71

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Bentley Nevada 330102-00-40-10-02-00: Product Overview, Parameters, Applications, Advantages, and Recommendations

Product Overview

The Bentley Nevada 330102-00-40-10-02-00 is an advanced vibration sensor from the 3300 Series, designed for real-time monitoring of critical machinery in industrial environments. This sensor is primarily used in applications where vibration levels are crucial for detecting faults such as imbalance, misalignment, and bearing wear in rotating machinery like turbines, compressors, motors, pumps, and fans.

The 330102-00-40-10-02-00 offers precise measurement capabilities, a broad frequency range, and a rugged, durable design. It is built to operate reliably in harsh industrial environments and can provide continuous, real-time vibration data to enhance maintenance strategies such as predictive maintenance and condition monitoring. This sensor helps identify problems early, reducing unplanned downtime and extending the lifespan of equipment.

Designed for both ease of integration and high performance, the 330102-00-40-10-02-00 supports flexible output signals (4-20 mA and 0-10 V) and can be integrated into existing monitoring systems without significant modifications.

Parameters

Below are the key specifications for the Bentley Nevada 330102-00-40-10-02-00:

| Parameter | Specification |

|---|---|

| Model Number | 330102-00-40-10-02-00 |

| Type | Vibration Sensor |

| Measurement Range | ±5000 g |

| Frequency Range | 0.1 Hz to 10 kHz |

| Output Signal | 4-20 mA / 0-10 V |

| Power Supply | 24 VDC ±20% |

| Dimensions | 150 mm x 110 mm x 95 mm |

| Weight | 1.8 kg |

| Accuracy | ±0.1% of full scale |

| Temperature Range | -40°C to +85°C |

| Housing Material | Stainless Steel (Corrosion-resistant) |

| Mounting Type | Screw Mount |

Applications

The Bentley Nevada 330102-00-40-10-02-00 vibration sensor is ideal for continuous monitoring in several industrial applications where machinery health is critical:

-

Turbines: This sensor detects early signs of imbalance, misalignment, or bearing failure in turbines, preventing costly repairs and extending equipment life.

-

Motors: It monitors the vibration levels of motors to identify mechanical failures such as misalignment or bearing damage, ensuring smooth operation.

-

Compressors: The sensor is used to monitor compressors for faults such as cavitation or imbalance, enabling early intervention and minimizing downtime.

-

Pumps: It helps identify issues in pumps, such as misalignment or bearing wear, improving operational efficiency and reducing repair costs.

-

Fans and Blowers: The sensor monitors fans and blowers for signs of wear or imbalance, ensuring optimal performance and preventing system failures.

Advantages

-

High Precision: The 330102-00-40-10-02-00 provides an accuracy of ±0.1% of full scale, offering highly reliable vibration data for early fault detection.

-

Broad Frequency Range: With a frequency range from 0.1 Hz to 10 kHz, it is capable of monitoring both low and high-frequency vibrations, making it suitable for a wide variety of industrial machines.

-

Durable and Reliable: Housed in a stainless steel casing, the sensor is corrosion-resistant and built to withstand harsh industrial environments, ensuring long-term reliability.

-

Supports Predictive Maintenance: Continuous vibration monitoring enables early detection of faults such as imbalance, misalignment, and bearing wear, which supports effective predictive maintenance programs.

-

Flexible Output Options: The sensor provides both 4-20 mA and 0-10 V output signals, making it versatile and easy to integrate into various monitoring systems.

Brand and Series

-

Brand: Bentley Nevada

-

Product Series: 3300 Series

Related Models (Same Series or Application)

Here are five related models from the 3300 Series or similar vibration sensors that provide comparable functionality for industrial applications:

| Model | Specification |

|---|---|

| 330102-00-40-05-02-00 | ±1000 g, 0.1 Hz to 10 kHz, 24 VDC, 4-20 mA output |

| 330102-00-35-10-02-05 | ±2000 g, 0.1 Hz to 10 kHz, 24 VDC, 4-20 mA output |

| 330102-00-28-05-02-00 | ±2000 g, 0.1 Hz to 10 kHz, 24 VDC, 4-20 mA output |

| 330102-00-40-10-02-05 | ±5000 g, 0.1 Hz to 10 kHz, 24 VDC, 4-20 mA output |

| 330102-00-28-10-02-00 | ±1000 g, 0.1 Hz to 10 kHz, 24 VDC, 4-20 mA output |

Popular Models (Same Brand)

Here are five other popular models from Bentley Nevada that are widely used in industrial machinery monitoring applications:

| Model | Specification |

|---|---|

| 330501-00-01-11-00 | ±5000 g, 0.1 Hz to 20 kHz, 24 VDC, 4-20 mA output |

| 330702-00-25-50-11-00 | ±2000 g, 0.1 Hz to 15 kHz, 24 VDC, 4-20 mA output |

| 330503-00-01-11-00 | ±1000 g, 0.2 Hz to 10 kHz, 24 VDC, 4-20 mA output |

| 330308-00-01-11-00 | ±3000 g, 0.5 Hz to 30 kHz, 24 VDC, 4-20 mA output |

| 330201-00-25-50-11-00 | ±1000 g, 0.1 Hz to 25 kHz, 24 VDC, 4-20 mA output |

FAQ (Frequently Asked Questions)

Q1: What is the measurement range of the Bentley Nevada 330102-00-40-10-02-00?

A1: The 330102-00-40-10-02-00 sensor has a measurement range of ±5000 g, allowing it to monitor both low and high levels of vibration in a variety of industrial machinery.

Q2: What is the frequency range of this sensor?

A2: The sensor operates within a frequency range of 0.1 Hz to 10 kHz, which enables it to detect both low and high-frequency vibrations.

Q3: What output signals are supported by the Bentley Nevada 330102-00-40-10-02-00?

A3: This sensor supports 4-20 mA and 0-10 V output signals, making it compatible with most industrial monitoring systems.

Q4: How accurate is the Bentley Nevada 330102-00-40-10-02-00?

A4: The sensor provides an accuracy of ±0.1% of full scale, ensuring precise vibration measurements that are critical for early fault detection.

Q5: What is the weight of the Bentley Nevada 330102-00-40-10-02-00?

A5: The sensor weighs approximately 1.8 kg, which allows for easy installation while maintaining durability and stability in harsh environments.

Q6: What temperature range can the Bentley Nevada 330102-00-40-10-02-00 operate in?

A6: The sensor can operate within a temperature range of -40°C to +85°C, making it suitable for a wide variety of industrial applications.

Q7: How does the Bentley Nevada 330102-00-40-10-02-00 support predictive maintenance?

A7: By continuously monitoring vibration levels, this sensor helps identify early signs of mechanical issues, such as misalignment, imbalance, or bearing wear, which is essential for predictive maintenance.

Q8: What industries benefit from using the Bentley Nevada 330102-00-40-10-02-00?

A8: This sensor is widely used in industries such as power generation, petrochemical, oil & gas, and heavy manufacturing for continuous machinery health monitoring.

Q9: What mounting method is used for the Bentley Nevada 330102-00-40-10-02-00?

A9: The sensor utilizes screw mounting, ensuring a secure and stable installation on machinery.

Q10: What power supply does the Bentley Nevada 330102-00-40-10-02-00 require?

A10: The Bentley Nevada 330102-00-40-10-02-00 operates on a 24 VDC power supply, with a tolerance of ±20%, ensuring compatibility with most industrial control systems.