ProductPRODUCT

Featured products

Contact Us

- Bently Nevada

- 330101-00-45-05-02-00

- 8mm Proximity Probe

- USA

- 0.5 meter

- 0.162kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 233

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

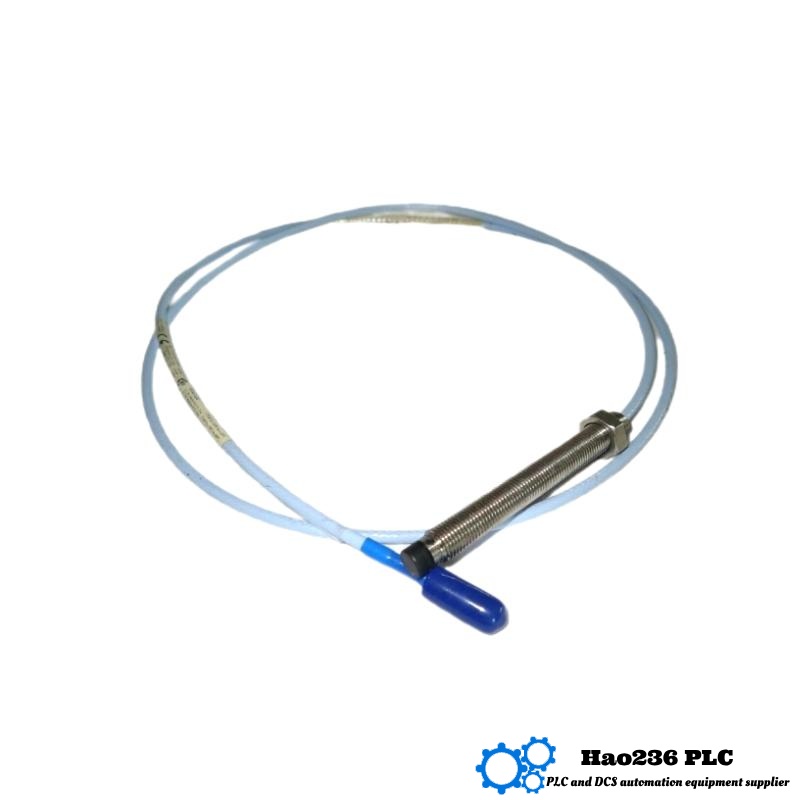

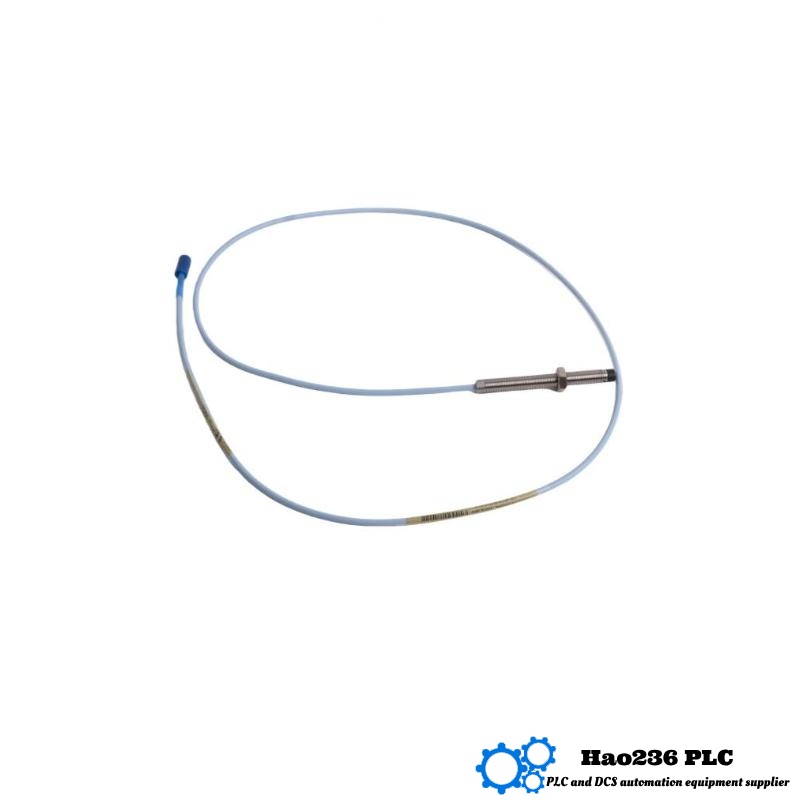

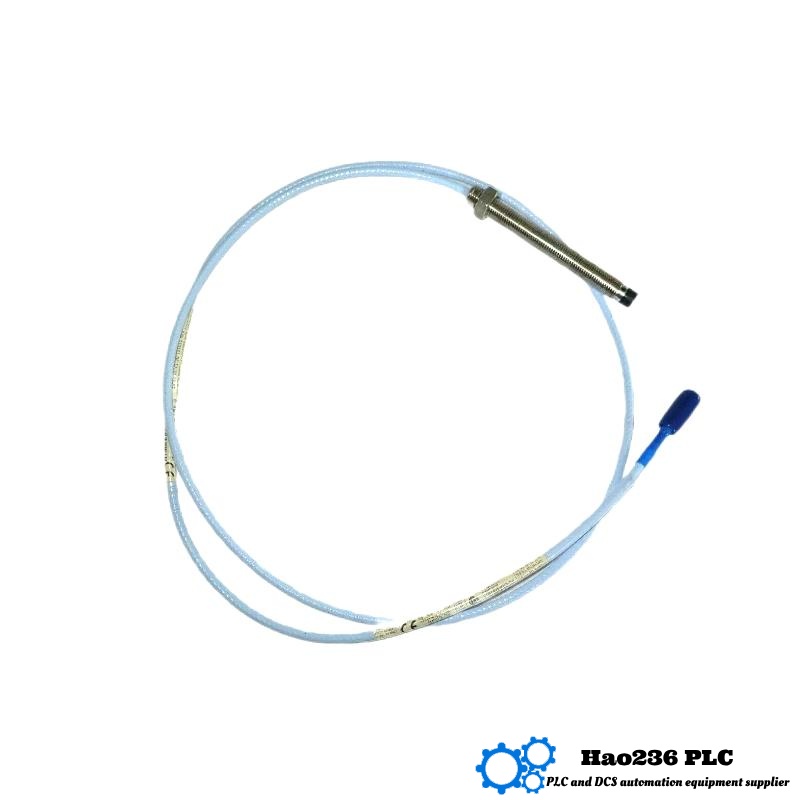

Bently Nevada 330101-00-45-05-02-00 8mm Proximity Probe

Product Introduction

The Bently Nevada 330101-00-45-05-02-00 is an 8mm proximity probe used to accurately measure the displacement of rotating machinery in various industrial applications. As part of the 3300 XL Series, this probe integrates seamlessly into Bently Nevada’s advanced machinery health monitoring systems. It utilizes eddy current technology, providing precise and reliable measurements of machine vibration and shaft displacement.

This model features a total length of 0.5 meter and weighs 0.162 kg, making it compact and lightweight for installation in confined spaces. With high sensitivity and durability, it is ideal for condition monitoring systems aimed at preventing mechanical failure in critical machinery.

The 330101-00-45-05-02-00 proximity probe is engineered to provide detailed, real-time data that supports predictive maintenance efforts, helping operators make informed decisions and reduce the risk of unexpected downtime.

Product Applications

The 330101-00-45-05-02-00 8mm proximity probe is used in a wide range of industries where machinery condition monitoring is crucial for ensuring reliability and minimizing downtime:

-

Power Generation: It is used to monitor turbines, generators, and other rotating equipment in power plants to detect early signs of damage and ensure smooth operation.

-

Oil & Gas: The probe is installed in critical assets such as gas turbines, compressors, and pumps in offshore platforms and refineries to improve operational efficiency and reduce failures.

-

Manufacturing: In factories, the probe monitors motors, compressors, and other rotating equipment to ensure uninterrupted production processes.

-

Aerospace: Used in high-speed rotating machinery, the probe ensures precise monitoring for aerospace applications, where machinery reliability is paramount.

-

Mining: The probe is employed in monitoring critical equipment such as crushers and mills, ensuring that these machines run efficiently and with minimal risk of breakdowns.

Product Advantages

-

High Sensitivity: The 330101-00-45-05-02-00 probe offers exceptional sensitivity to small displacements, providing early warning signs of potential issues before they lead to failures.

-

Durability: Designed for harsh industrial environments, the probe is robust and resistant to wear, providing long-term reliability.

-

Compact Size: With a total length of 0.5 meter and a weight of 0.162 kg, this probe is perfect for installations where space is limited or where lightweight equipment is required.

-

Seamless Integration: Being part of the 3300 XL Series, the probe integrates effortlessly with other Bently Nevada products, allowing for a comprehensive machinery health monitoring system.

-

Accurate Data: It provides highly accurate measurements using eddy current technology, which is crucial for accurate predictive maintenance and condition monitoring.

-

Cost-Efficiency: By enabling early detection of mechanical faults, the probe helps reduce maintenance costs and prevent unexpected failures, leading to long-term savings.

Brand

-

Bently Nevada: A leading provider of machinery health monitoring solutions, Bently Nevada offers a range of products designed to optimize machine reliability and prevent unexpected breakdowns. With over 60 years of industry expertise, Bently Nevada is known for its high-precision sensors and advanced monitoring systems.

Series

-

3300 XL Series: The 3300 XL Series is a comprehensive suite of monitoring devices designed to provide high-precision measurement and early detection of machinery faults. These products help ensure maximum uptime and reliability of industrial machinery, enabling companies to adopt proactive maintenance strategies.

Specifications Table

| Parameter | Value |

|---|---|

| Model Number | 330101-00-45-05-02-00 |

| Type | 8mm Proximity Probe |

| Total Length | 0.5 meter |

| Weight | 0.162 kg |

| Frequency Range | 0 – 100 kHz |

| Sensitivity | 5 mV/µm |

| Temperature Range | –40°C to +120°C |

| Vibration Range | 0.001 mm to 10 mm |

| Operating Principle | Eddy Current |

| Maximum Probe Gap | 10 mm |

| Environmental Protection | IP65 |

| Cable Length | 0.5 meter |

| Mounting Type | Flanged or threaded mounting |

| Operating Environment | Harsh industrial environments |

Recommended 5 Related Models from the 3300 XL Series

| Model | Description | Key Parameters |

|---|---|---|

| 330130-040-00 | 8mm Proximity Probe with standard cable | 1.0 meter length, 0.32 kg weight |

| 330180-91-CN | 8mm Proximity Probe with high-frequency capabilities | 1.2 meter length, 0.35 kg weight |

| 330060-04-02 | 5mm Proximity Probe for low-speed machinery | 0.8 meter length, 0.30 kg weight |

| 330019-04-02 | High-resolution proximity probe for precise measurements | 1.0 meter length, 0.33 kg weight |

| 330130-04-00 | Extended cable version of 8mm proximity probe | 1.5 meter length, 0.35 kg weight |

Recommended 5 Popular Models from Bently Nevada

| Model | Description | Key Parameters |

|---|---|---|

| 330130-91-00 | 8mm Proximity Probe for general use | 0.9 meter length, 0.33 kg weight |

| 330500-04-00 | Vibration monitoring system with high-performance sensors | 1.0 meter length, 0.45 kg weight |

| 330503-04-01 | Vibration sensor with integrated signal conditioning | 1.0 meter length, 0.45 kg weight |

| 330710-04-00 | Vibration transmitter for continuous machinery health monitoring | 1.0 meter length, 0.38 kg weight |

| 330702-04-02 | Long-cable proximity probe for extended reach | 1.5 meter length, 0.40 kg weight |

FAQ (10 Questions and Answers)

Q1: What is the purpose of the Bently Nevada 330101-00-45-05-02-00 proximity probe?

A1: The 330101-00-45-05-02-00 probe is designed to accurately measure shaft displacement and vibration, providing critical data for machinery health monitoring and predictive maintenance.

Q2: What is the length of the Bently Nevada 330101-00-45-05-02-00 probe?

A2: The probe has a total length of 0.5 meters, making it suitable for various installations, including those in confined spaces.

Q3: How much does the Bently Nevada 330101-00-45-05-02-00 probe weigh?

A3: The probe weighs only 0.162 kg, making it lightweight and easy to handle during installation.

Q4: What type of technology does this probe use to measure vibration?

A4: The probe uses eddy current technology, which is highly sensitive to small displacements and vibration changes.

Q5: Can the probe be used with other Bently Nevada products?

A5: Yes, it integrates seamlessly with other products in the 3300 XL Series, allowing for a complete and reliable machinery monitoring solution.

Q6: What is the operating temperature range of the Bently Nevada 330101-00-45-05-02-00 probe?

A6: The probe operates within a temperature range of –40°C to +120°C, ensuring its performance in a variety of industrial environments.

Q7: What is the frequency range of the probe?

A7: The frequency range of the probe is 0 to 100 kHz, making it suitable for measuring high-speed machinery.

Q8: What is the maximum gap the probe can measure?

A8: The maximum probe gap is 10 mm, allowing it to detect small displacements in machinery.

Q9: What mounting options are available for this probe?

A9: The 330101-00-45-05-02-00 probe can be mounted using either flanged or threaded mounting methods, providing flexibility for various installations.

Q10: What industries use the Bently Nevada 330101-00-45-05-02-00 probe?

A10: This probe is used in industries such as power generation, oil and gas, aerospace, and manufacturing for machinery condition monitoring.