ProductPRODUCT

Featured products

Contact Us

- Bently Nevada

- 330101-00-28-10-02-CN

- 8mm Proximity Probe

- USA

- 1.0 meter

- 0.323kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 229

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

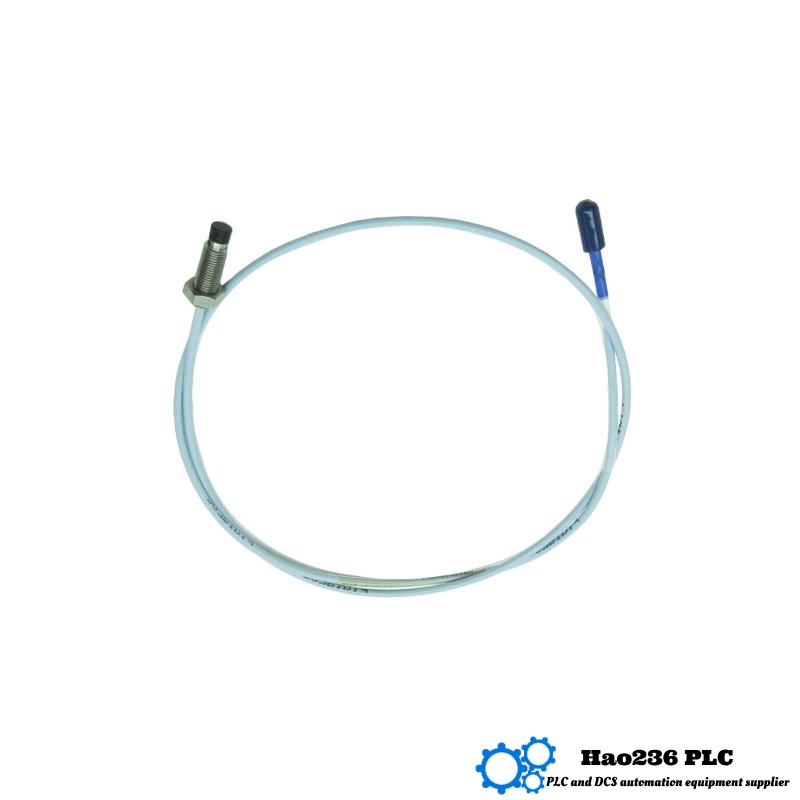

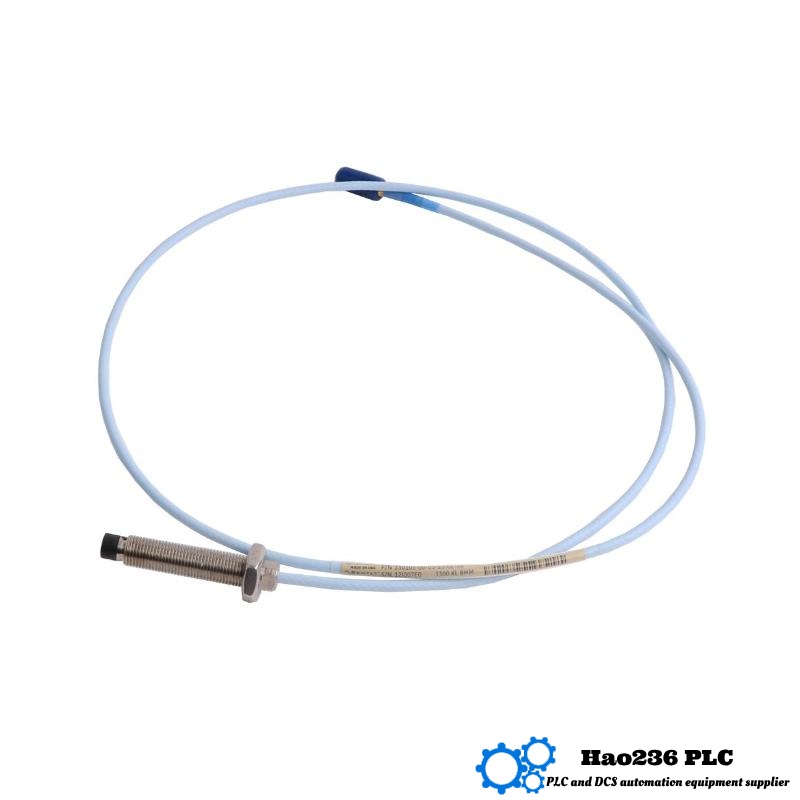

Bently Nevada 330101-00-28-10-02-CN 8mm Proximity Probe

Product Introduction

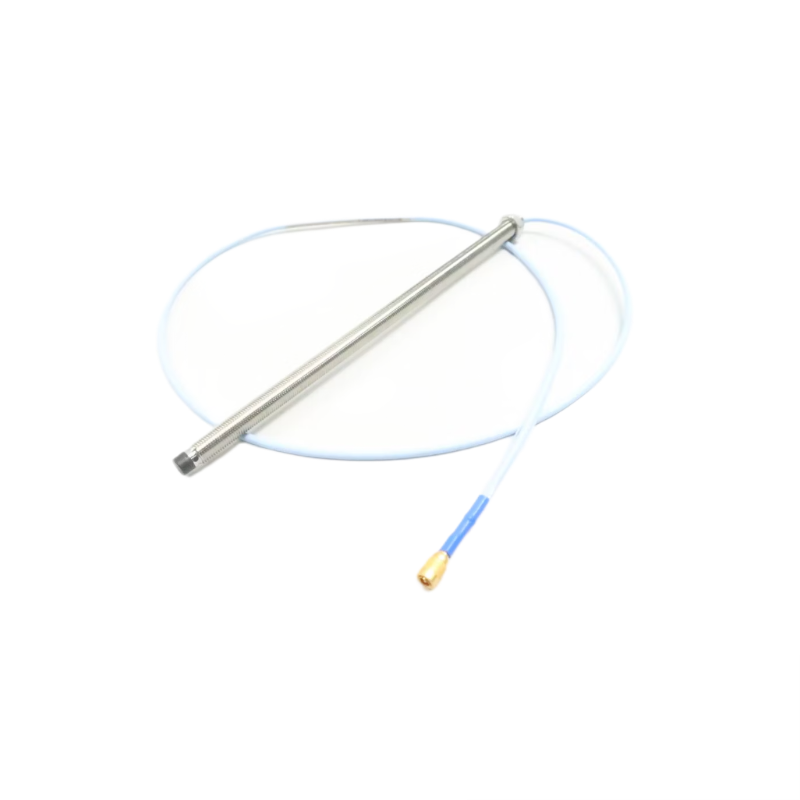

The Bently Nevada 330101-00-28-10-02-CN is a high-precision 8mm proximity probe designed to monitor the health and condition of rotating machinery, such as motors, turbines, and pumps. This probe is part of the renowned 3300 XL series, offering advanced capabilities for vibration and position measurement in harsh industrial environments. The 330101-00-28-10-02-CN probe provides reliable and accurate data, which is critical for predictive maintenance and early fault detection, helping to prevent costly downtime and improve the reliability of machinery.

Product Specifications

| Parameter | Value |

|---|---|

| Model | 330101-00-28-10-02-CN |

| Type | 8mm Proximity Probe |

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Probe Diameter | 8mm |

| Sensing Range | 0 to 1000 mils |

| Material | Stainless Steel |

| Operating Temperature | –40°C to 120°C |

| Cable Length | Customizable (Up to 3 meters) |

| Mounting Type | Standard Probe Mounting |

Product Applications

The Bently Nevada 330101-00-28-10-02-CN proximity probe is primarily used for condition monitoring in rotating machinery. Its primary applications include:

-

Vibration Monitoring: Used to monitor vibration levels in turbines, motors, and pumps to ensure smooth operation.

-

Position Measurement: Provides precise measurement of the shaft position in machinery, aiding in alignment checks.

-

Condition-Based Maintenance: Essential for predictive maintenance strategies in industries like oil and gas, power generation, and manufacturing.

-

Rotating Machinery Health Monitoring: Helps assess the health of critical machinery, reducing the risk of failure and improving equipment uptime.

-

Process Optimization: Used in conjunction with vibration analysis systems to optimize machine performance and efficiency in a range of industries.

Product Advantages

-

High Accuracy: The 330101-00-28-10-02-CN proximity probe provides precise measurement of vibration and shaft position, ensuring that any potential issues are detected early.

-

Durable Design: Built with high-quality stainless steel, the probe is capable of withstanding harsh industrial environments, ensuring long-term performance.

-

Wide Temperature Range: It operates effectively in temperatures ranging from –40°C to 120°C, making it suitable for a wide variety of industrial settings.

-

Reduced Downtime: By using this probe for predictive maintenance, companies can detect issues before they lead to machine failure, reducing the need for unscheduled downtime.

-

Versatile Applications: The probe is suitable for use in many different industries, including power generation, oil and gas, and heavy manufacturing, due to its flexibility and robust design.

Brand: Bently Nevada

Bently Nevada is a recognized global leader in condition monitoring and asset protection solutions. The company provides advanced instrumentation for monitoring vibration, temperature, position, and other vital parameters in rotating machinery. Their products are widely used in industries such as oil and gas, power generation, and manufacturing to ensure the safe and reliable operation of machinery. The 330101-00-28-10-02-CN probe is a part of the Bently Nevada 3300 XL series, which is known for its superior accuracy and reliability in real-time condition monitoring.

Series: 3300 XL Series

The 3300 XL series from Bently Nevada is known for its high precision and reliability in monitoring and protecting critical machinery. The series includes proximity probes, vibration monitors, and other advanced sensors designed to ensure optimal performance of rotating equipment. The 3300 XL series offers a comprehensive solution for predictive maintenance and condition-based monitoring, helping industries prevent costly repairs and reduce unplanned downtime.

Recommended Models from the Same Series or Related

| Model | Description | Key Features | Dimensions | Weight |

|---|---|---|---|---|

| 330103-00-28-10-02-CN | 8mm Proximity Probe | High-precision, versatile monitoring | 1.0 meter | 0.32 kg |

| 330103-00-30-10-02-CN | 5mm Proximity Probe | Accurate measurement, flexible range | 1.0 meter | 0.30 kg |

| 330104-00-28-10-02-CN | 8mm Extended Proximity Probe | Designed for extended measuring range | 1.2 meter | 0.34 kg |

| 330400-00-02-10-00-CN | Vibration Sensor Module | Condition monitoring with high precision | 0.8 meter | 0.35 kg |

| 330101-00-28-10-05-CN | 8mm Proximity Probe, Long Range | Longer range for extreme conditions | 1.5 meter | 0.36 kg |

Popular Models from Bently Nevada

| Model | Description | Key Features | Dimensions | Weight |

|---|---|---|---|---|

| 330502-00-03-00-CN | Vibration Transmitter Module | Real-time vibration measurement | 180 x 140 x 40 mm | 1.2 kg |

| 330701-00-01-00-CN | Accelerometer (Vibration Sensor) | High-frequency vibration monitoring | 120 x 90 x 30 mm | 0.9 kg |

| 330705-00-01-00-CN | Vibration Monitor for Industrial Equipment | Continuous vibration tracking | 200 x 150 x 60 mm | 2.3 kg |

| 330410-00-02-10-01-CN | Temperature Transmitter Module | Accurate temperature monitoring | 140 x 110 x 50 mm | 0.8 kg |

| 350100-00-02-00-CN | Signal Conditioning Module | Signal amplification and processing | 250 x 200 x 80 mm | 2.5 kg |

FAQ (Frequently Asked Questions)

Q1: What is the primary function of the Bently Nevada 330101-00-28-10-02-CN probe?

A1: The primary function is to monitor vibration and shaft position in rotating machinery to detect potential issues early.

Q2: What is the total length of the Bently Nevada 330101-00-28-10-02-CN probe?

A2: The total length of the probe is 1.0 meter.

Q3: What material is the probe made from?

A3: The probe is made of stainless steel, providing durability in harsh industrial environments.

Q4: What is the sensing range of the probe?

A4: The sensing range is 0 to 1000 mils.

Q5: Can the Bently Nevada 330101-00-28-10-02-CN probe be used in high-temperature environments?

A5: Yes, the probe operates in temperatures ranging from –40°C to 120°C.

Q6: What is the weight of the Bently Nevada 330101-00-28-10-02-CN probe?

A6: The probe weighs 0.323 kg.

Q7: What industries can benefit from using this proximity probe?

A7: Industries such as power generation, oil and gas, and manufacturing benefit from using this proximity probe for predictive maintenance and machinery health monitoring.

Q8: How does the Bently Nevada 330101-00-28-10-02-CN improve machinery reliability?

A8: By providing early detection of vibration issues and misalignments, the probe helps prevent machine failure and optimize performance.

Q9: What is the mounting type of the probe?

A9: The probe is designed for standard probe mounting.

Q10: How does the proximity probe contribute to predictive maintenance?

A10: The proximity probe provides accurate vibration and position data, which can be used to predict potential failures, reducing downtime and maintenance costs.