ProductPRODUCT

Featured products

Contact Us

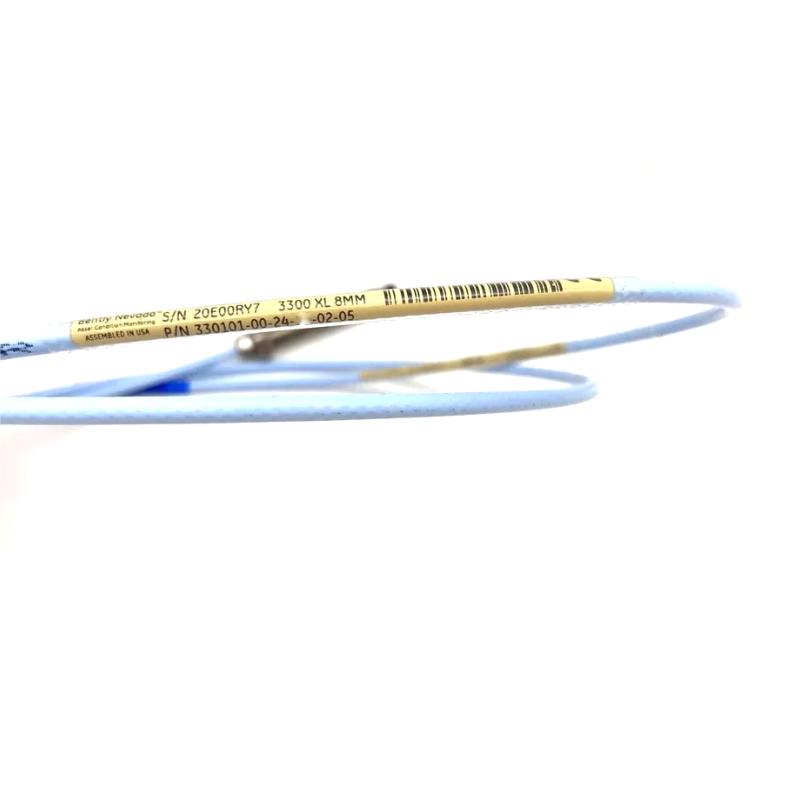

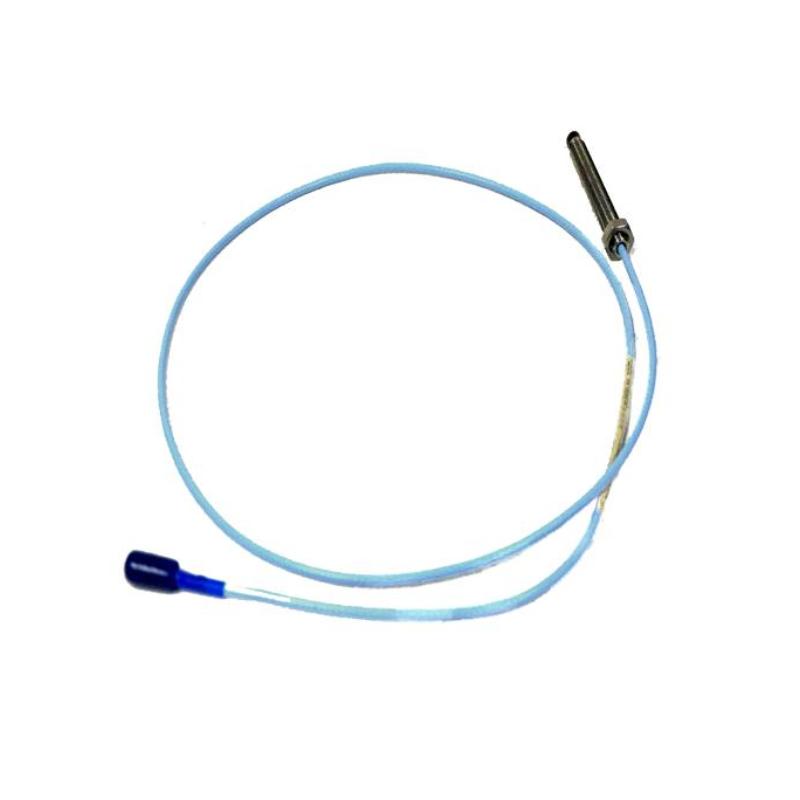

- Bently Nevada

- 330101-00-24-05-02-05

- 3300 XL 8 mm Proximity Probes

- USA

- 160 mm x 130 mm x 65 mm

- 1.8kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 257

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Bentley Nevada 330101-00-24-05-02-05 Product Overview

Product Description

The Bentley Nevada 330101-00-24-05-02-05 is a robust and advanced vibration monitoring system from the renowned Bentley Nevada 3300 Series. It is designed to continuously monitor the health of critical rotating machinery, such as motors, compressors, turbines, and pumps, providing valuable insights into the condition of equipment. This allows operators to detect potential mechanical issues, including misalignment, imbalance, and bearing wear, before they lead to unplanned downtime or catastrophic failures.

The 330101-00-24-05-02-05 integrates advanced signal processing and diagnostic capabilities, offering high-precision vibration measurements. It supports multiple output types, including analog and digital signals, making it compatible with various industrial monitoring and control systems. This model is ideal for industries where uptime is critical, such as power generation, chemical processing, oil and gas, and manufacturing.

With its rugged design and advanced features, the 330101-00-24-05-02-05 provides operators with a reliable tool to ensure that critical assets are continuously monitored, enabling predictive maintenance and reducing the overall cost of repairs and downtime.

Key Features

-

Real-Time Vibration Monitoring: Provides continuous real-time monitoring of vibration parameters such as velocity, acceleration, and displacement to detect early signs of equipment malfunction.

-

Advanced Diagnostics: The system uses sophisticated signal processing algorithms to detect faults like misalignment, imbalance, and bearing wear, providing early warning signs before failures occur.

-

Flexible Integration: Supports a variety of output options, including analog, digital, and Modbus, making it easy to integrate with existing plant control systems and monitoring platforms.

-

Durability: Designed for harsh industrial environments, it features an IP66 rating, which ensures protection against dust and water, making it suitable for high-temperature, high-vibration, and wet conditions.

-

Predictive Maintenance Capabilities: By monitoring machinery continuously, the system allows for predictive maintenance, which reduces the need for reactive maintenance and minimizes the risk of catastrophic failures.

-

Customizable Alarms and Thresholds: Operators can configure personalized alarm thresholds to suit specific equipment conditions, ensuring immediate detection of potential faults.

-

Low Cost of Ownership: By minimizing downtime and reducing maintenance costs, the system provides a high return on investment over time.

Product Advantages

-

Early Fault Detection: By identifying mechanical issues early, such as imbalance or misalignment, the 330101-00-24-05-02-05 helps prevent equipment failure and costly unplanned downtime.

-

Extended Equipment Life: Continuous monitoring ensures machinery operates at peak efficiency, reducing wear and tear and extending the lifespan of critical assets.

-

Improved Safety: Early detection of problems ensures that equipment is maintained before failures can cause dangerous operational conditions or safety hazards.

-

Cost-Effective Maintenance: Proactive monitoring enables condition-based maintenance, reducing the frequency and cost of unnecessary repairs and allowing maintenance to be performed based on actual machine condition.

-

Enhanced Operational Efficiency: By keeping machines running efficiently, this system helps reduce energy consumption and ensures optimal performance in industrial applications.

-

Versatile Applications: Suitable for a wide range of rotating machinery and various industrial environments, making it highly adaptable across multiple industries.

Applications

The Bentley Nevada 330101-00-24-05-02-05 is designed for use in various industries, especially those involving critical machinery that requires constant monitoring to avoid failure. Key applications include:

-

Power Generation: Ideal for monitoring turbines, compressors, and generators, ensuring continuous and efficient operation in power plants.

-

Oil & Gas: Used in upstream and downstream operations, monitoring pumps, compressors, and motors to maintain operational reliability in remote or harsh environments.

-

Chemical Processing: Monitors pumps, motors, and reactors in chemical plants, reducing the risk of breakdowns and improving overall operational safety.

-

Mining: Suitable for heavy-duty equipment such as crushers, mills, and conveyors, ensuring smooth operation and reducing the risk of unplanned downtime in mining operations.

-

Manufacturing: In manufacturing plants, the system is used to monitor motors, fans, and conveyors, ensuring smooth production lines and minimizing production disruptions.

Brand and Series

-

Brand: Bentley Nevada (Part of Baker Hughes)

-

Series: 3300 Series Vibration Monitoring Systems

Product Parameters

Here is a detailed overview of the Bentley Nevada 330101-00-24-05-02-05 specifications:

| Parameter | Specification |

|---|---|

| Model | 330101-00-24-05-02-05 |

| Functionality | Vibration Monitoring & Diagnostics |

| Input Voltage | 24V DC |

| Signal Type | Vibration (Velocity, Acceleration, Displacement) |

| Operating Temperature | -20°C to +70°C |

| Dimensions (H x W x D) | 160 mm x 130 mm x 65 mm |

| Weight | 1.8 kg |

| Mounting Type | DIN Rail/Panel Mount |

| Data Output | Analog, Digital, Modbus |

| Environmental Protection | IP 66 |

| Display Type | LED Indicator/Monitor Display |

Recommended Models from the Same Series

| Model | Specification |

|---|---|

| 330101-00-22-10-02-00 | Vibration Transmitter for Low-Speed Machines |

| 330101-00-24-05-02-00 | Multi-Channel Vibration Monitoring System |

| 330200-00-10-00-00 | Advanced Vibration Diagnostics Module |

| 330101-00-22-05-02-05 | Vibration Monitoring for Heavy-Duty Machines |

| 330300-00-20-00-01 | Comprehensive Condition Monitoring System |

Recommended Models from Bentley Nevada

| Model | Specification |

|---|---|

| 3500/42M | Machinery Protection and Monitoring System |

| 3500/22M | Vibration Monitoring Module for Critical Equipment |

| 3500/44M | Condition Monitoring Module |

| 3300/23 | High-Sensitivity Vibration Sensor |

| 3300/21 | Compact Vibration Transducer |

Frequently Asked Questions (FAQ)

-

Q: What does the 330101-00-24-05-02-05 primarily monitor?

A: The system monitors the vibration of rotating machinery, including parameters such as velocity, acceleration, and displacement, to detect early signs of mechanical problems. -

Q: How does the system detect faults?

A: It uses advanced algorithms to analyze vibration signals, identifying patterns that indicate potential issues like misalignment, imbalance, or bearing wear. -

Q: Can the system be integrated with existing control systems?

A: Yes, the system supports multiple output types (analog, digital, Modbus), allowing easy integration with existing plant control systems and monitoring platforms. -

Q: What is the environmental protection rating of this device?

A: The 330101-00-24-05-02-05 has an IP66 rating, meaning it is protected against dust and water ingress, making it suitable for harsh industrial environments. -

Q: What temperature range does the system operate in?

A: The system is designed to operate in a temperature range from -20°C to +70°C, making it suitable for use in diverse environmental conditions. -

Q: Is this system suitable for both low-speed and high-speed machines?

A: Yes, it is designed to monitor both low-speed and high-speed machinery with equal precision. -

Q: How customizable are the alarm thresholds?

A: The alarm thresholds are fully customizable, allowing operators to set specific limits for different equipment conditions, ensuring accurate fault detection. -

Q: How is the system mounted?

A: The 330101-00-24-05-02-05 can be mounted using DIN rails or directly onto panels, making installation flexible and straightforward. -

Q: Can the system provide real-time data?

A: Yes, it continuously monitors the machinery and provides real-time vibration data, allowing for immediate action if problems are detected. -

Q: What maintenance practices are required for this system?

A: Minimal maintenance is required, but regular system checks and calibration are recommended to ensure accurate measurements over time.