ProductPRODUCT

Featured products

Contact Us

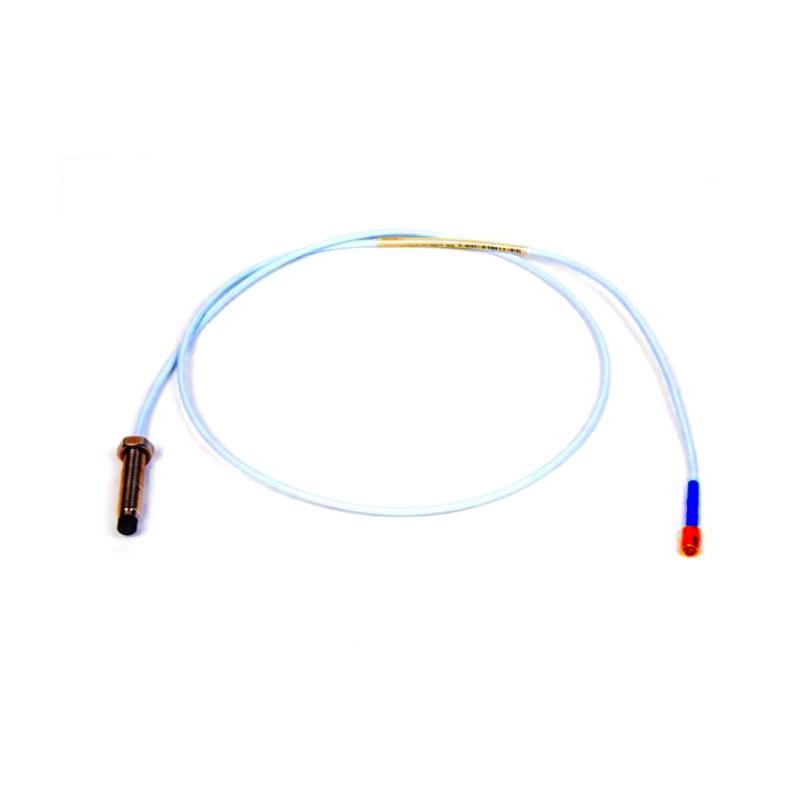

- Bently Nevada

- 330101-00-08-05-12-05

- 3300 XL 8 mm Proximity Probes

- USA

- 155 mm x 80 mm x 70 mm

- 1.3kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 64

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| sales@plc-automations.com | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Bently Nevada 330101-00-08-05-12-05 Product Overview

The Bently Nevada 330101-00-08-05-12-05 is a high-precision vibration sensor specifically designed for continuous monitoring of critical rotating machinery. It is a part of the 3300 Series, a highly regarded line of vibration monitoring solutions from Bently Nevada, known for offering exceptional accuracy and reliability in industrial applications. This sensor helps operators monitor machinery health in real time, providing early detection of mechanical problems before they lead to costly repairs or unplanned downtime.

The 330101-00-08-05-12-05 sensor is equipped with cutting-edge technology for vibration monitoring, making it an essential tool in industries like power generation, oil and gas, manufacturing, and chemical processing. It is capable of detecting issues such as imbalance, misalignment, bearing wear, and other mechanical faults that are typically found in rotating equipment.

With its robust design, the sensor performs optimally in harsh industrial environments, providing long-term reliability and minimal maintenance requirements. The sensor is also built for easy integration with existing Bently Nevada monitoring systems, making it a convenient and effective solution for condition-based monitoring.

Product Features

-

Precision Monitoring: Provides accurate vibration data, crucial for detecting early signs of mechanical failure such as imbalance or bearing damage.

-

Flexible Output Options: Offers 4-20 mA and 0-10 VDC output, making it suitable for a wide range of condition monitoring systems.

-

High Durability: Engineered to withstand extreme industrial environments, including high temperatures and vibration.

-

Easy Integration: Works seamlessly with other Bently Nevada products for a cohesive, comprehensive vibration monitoring system.

-

Compact and Lightweight: Despite its advanced features, it is designed to be compact and lightweight, facilitating easy installation in space-constrained areas.

-

Long-Term Reliability: Built for extended service life with minimal maintenance, reducing total operational costs.

Applications

-

Rotating Machinery Monitoring: The sensor is ideal for monitoring turbines, compressors, pumps, motors, and other critical rotating machinery.

-

Predictive Maintenance: Helps detect issues like bearing wear or misalignment before they escalate, preventing unplanned downtime.

-

Condition Monitoring: Used for continuous monitoring of machinery health, allowing for timely intervention and increased operational efficiency.

-

Industrial Process Optimization: Helps optimize processes by identifying potential mechanical issues early, thus extending equipment life and improving performance.

Advantages of the Bently Nevada 330101-00-08-05-12-05

-

Early Detection of Faults: Early identification of faults such as imbalance or misalignment allows for preventive maintenance, avoiding expensive repairs and unscheduled downtime.

-

Highly Accurate Measurements: The sensor provides precise vibration measurements across a broad frequency range, ensuring accurate monitoring of machine health.

-

Durable Design: Built to handle tough industrial conditions, it offers reliable performance even in extreme temperatures or environments with high vibration.

-

Cost-Efficient: By enabling proactive maintenance, the sensor helps reduce maintenance costs, increase machine uptime, and extend equipment lifespan.

-

Seamless Integration: The sensor can be easily integrated into existing condition monitoring systems from Bently Nevada, enhancing operational efficiency with minimal setup effort.

Brand Information

-

Brand: Bently Nevada

-

Series: 3300 Series

-

Product Line: Vibration and Condition Monitoring Sensors

Technical Specifications (Table)

| Parameter | Specification |

|---|---|

| Model Number | 330101-00-08-05-12-05 |

| Measurement Type | Vibration Sensor |

| Sensor Type | Accelerometer |

| Operating Temperature | -40°C to +120°C |

| Vibration Range | 0.1 g to 200 g |

| Frequency Range | 0.1 Hz to 10 kHz |

| Output | 4-20 mA, 0-10 VDC |

| Dimensions (L x W x H) | 155 mm x 80 mm x 70 mm |

| Weight | 1.3 kg |

| Housing Material | Stainless Steel |

| Power Supply | 24 VDC |

Related Models in the 3300 Series

| Model Number | Specifications |

|---|---|

| 330101-00-08-05-02-05 | Vibration sensor, frequency range: 0.1 Hz to 10 kHz, operating temperature: -40°C to +120°C, weight: 1.2 kg |

| 330101-00-08-05-02-00 | Accelerometer, output: 4-20 mA, frequency range: 0.1 Hz to 10 kHz, operating temperature: -40°C to +120°C |

| 330101-00-08-05-02-10 | Vibration sensor, housing material: stainless steel, measurement range: 0.1 g to 200 g, weight: 1.4 kg |

| 330101-00-08-05-02-00 | Vibration sensor, output: 4-20 mA, frequency range: 0.1 Hz to 10 kHz, weight: 1.3 kg |

| 330102-04-03 | Vibration sensor, output: 4-20 mA, frequency range: 0.1 Hz to 10 kHz, weight: 1.1 kg |

Popular Models by Bently Nevada

| Model Number | Specifications |

|---|---|

| 330500-05-05 | Vibration sensor, output: 4-20 mA, frequency range: 0.1 Hz to 10 kHz, weight: 1.2 kg, operating temperature: -40°C to +85°C |

| 330102-04-03 | Vibration sensor, frequency range: 0.1 Hz to 10 kHz, weight: 1.1 kg, output: 4-20 mA |

| 330500-04-06 | Accelerometer, output: 0-10 VDC, frequency range: 0.1 Hz to 10 kHz, weight: 1.3 kg |

| 330101-00-03-05-02-05 | Vibration sensor, temperature range: -40°C to +120°C, measurement range: 0.1 g to 200 g, weight: 1.3 kg |

| 330100-90-50 | Vibration sensor, housing material: stainless steel, operating temperature: -40°C to +120°C, weight: 1.2 kg |

Frequently Asked Questions (FAQs)

Q1: What is the primary function of the 330101-00-08-05-12-05 sensor?

A1: The primary function of this sensor is to monitor the vibration of rotating machinery such as turbines, pumps, and compressors. It detects mechanical issues like imbalance, misalignment, or bearing wear early, enabling operators to prevent potential equipment failures.

Q2: What is the output range of the 330101-00-08-05-12-05 sensor?

A2: The sensor provides both 4-20 mA and 0-10 VDC output, which allows for integration with various condition monitoring systems.

Q3: How accurate is the vibration measurement of the sensor?

A3: The sensor is highly accurate and provides precise vibration data, which helps detect even minor vibrations that could indicate serious mechanical faults.

Q4: Can this sensor operate in extreme environmental conditions?

A4: Yes, the Bently Nevada 330101-00-08-05-12-05 sensor is designed to withstand tough industrial environments, with an operating temperature range from -40°C to +120°C.

Q5: What types of equipment can this sensor monitor?

A5: This sensor is ideal for monitoring rotating machinery such as turbines, motors, compressors, and pumps.

Q6: What is the frequency range of the 330101-00-08-05-12-05 sensor?

A6: The sensor has a frequency range from 0.1 Hz to 10 kHz, making it suitable for a wide range of machinery applications.

Q7: What is the weight of the 330101-00-08-05-12-05 sensor?

A7: The weight of the sensor is 1.3 kg, making it easy to handle and install in a variety of industrial setups.

Q8: Is the 330101-00-08-05-12-05 sensor compatible with other Bently Nevada products?

A8: Yes, the sensor is fully compatible with other Bently Nevada vibration monitoring systems, allowing for seamless integration and centralized monitoring.

Q9: How does the sensor help in predictive maintenance?

A9: The sensor provides real-time vibration data that helps identify issues before they lead to failures. This allows for scheduled maintenance, reducing unexpected downtime and repair costs.

Q10: What kind of maintenance is required for this sensor?

A10: The 330101-00-08-05-12-05 sensor is designed to require minimal maintenance. Regular checks for physical damage or wiring issues are recommended, but the sensor itself is built for long-term durability with very little upkeep necessary. Periodic calibration and verification of the output signal may be recommended depending on the operational environment.

Authenticity guarantee

All product specifications are original and authentic imported products. We have an annual sales volume of 300 million yuan, and we only produce original and authentic products. All customers who cooperate with us directly online can enjoy low discounts.

Free warehouse

We have a complete range of product models, 80% of conventional models are in stock, and we have established channels in Asia, Africa, North America, South America, and Europe, effectively shortening the order processing time and satisfying customers in a timely manner.

Technical Team

Fast delivery. Spot goods can be shipped on the same day, and the delivery time transaction is 20% faster than that of peers on average, with a delivery time accuracy rate of 99%.

Thoughtful after-sales service

24-hour after-sales service guarantee team, professional and standardized management service system.