ProductPRODUCT

Featured products

Contact Us

- Honeywell

- 620-2030 6202030

- Processor Module

- USA

- 245 × 130 × 65 mm

- 1.37kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 5

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

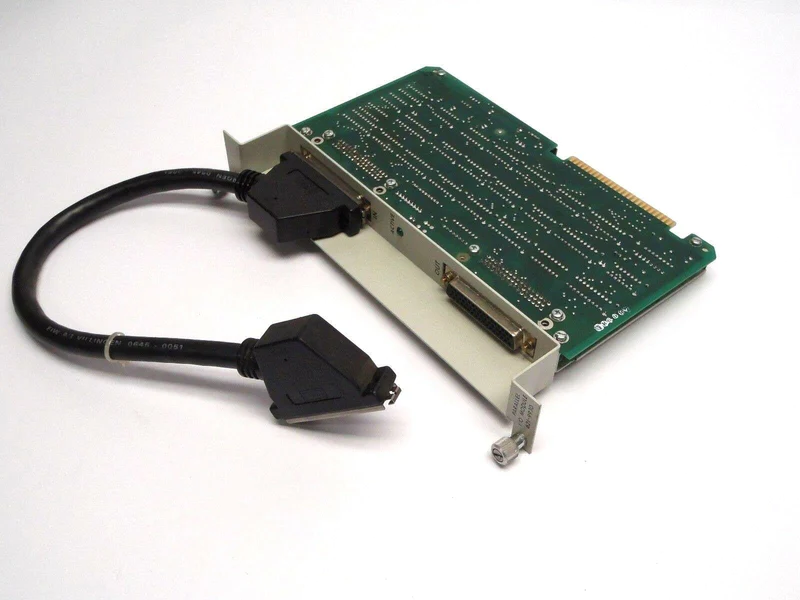

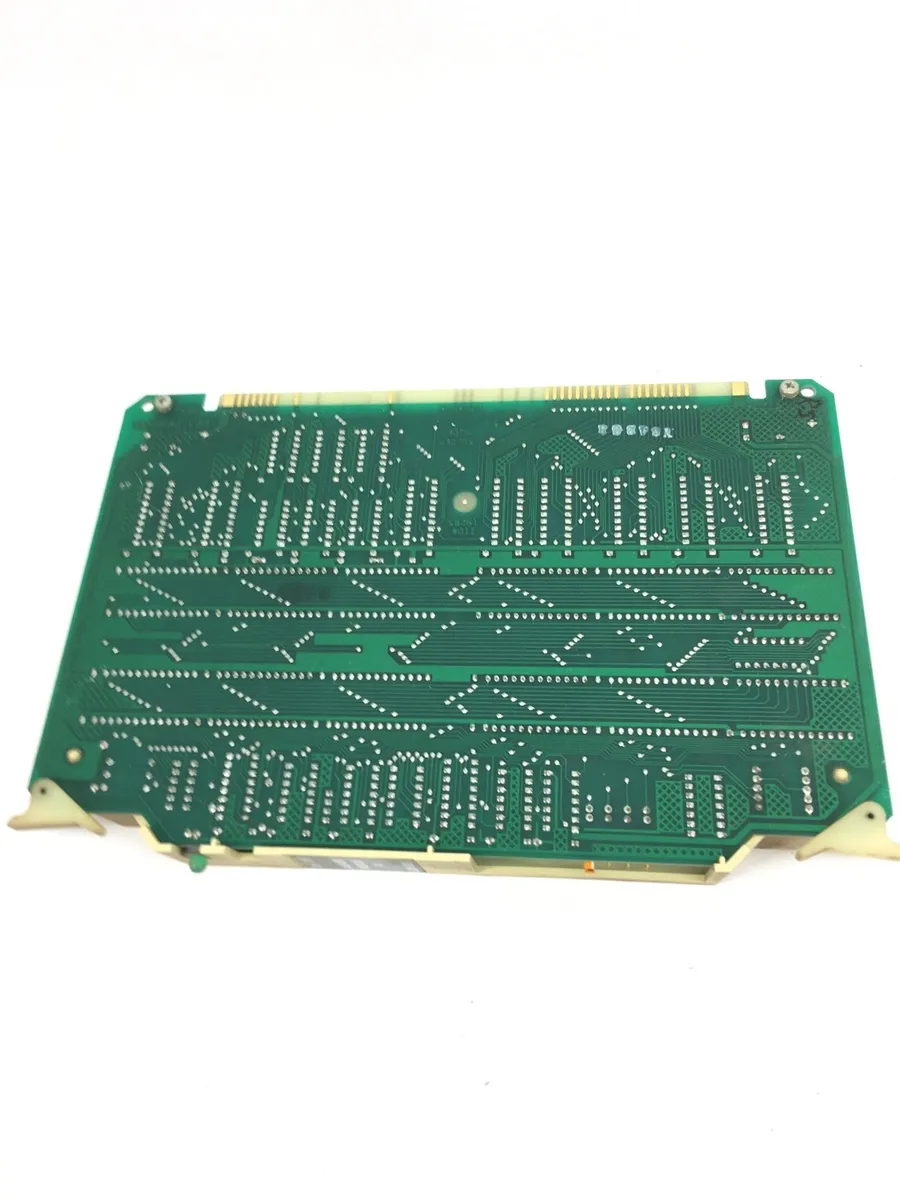

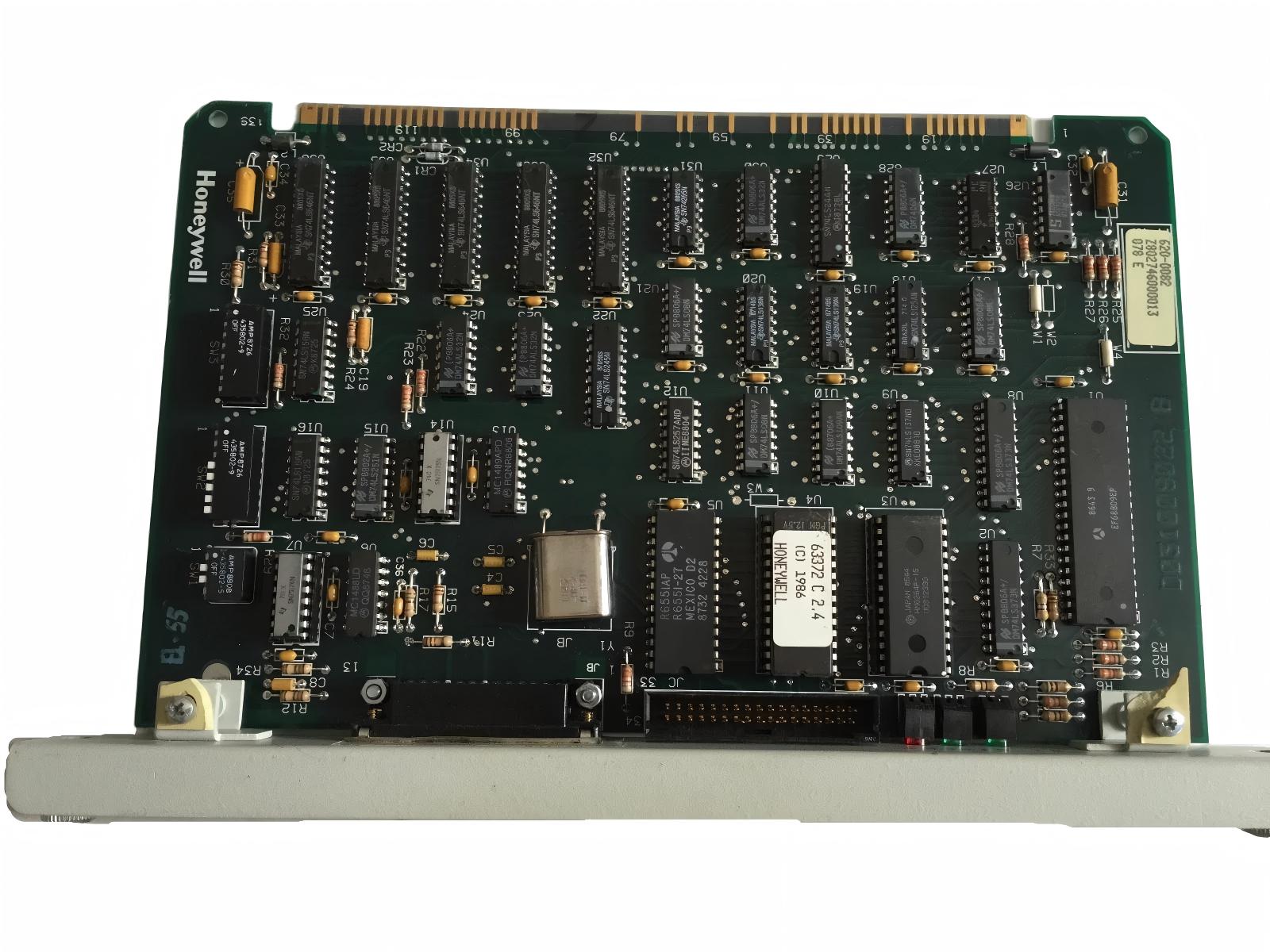

Honeywell 620‑2030 PLC Control and Interface Module

Product Basic Information

-

Model: 620‑2030

-

Product Type: PLC Control and Interface Module

-

Brand: Honeywell

-

Series: IPC 620 PLC Module Series

-

Category: Industrial Automation / PLC Logic & Communication

Product Introduction

The Honeywell 620‑2030 is an advanced PLC control and interface module designed for industrial automation systems requiring high reliability and precision.

This module serves as a bridge between central PLC CPUs and distributed field devices, including I/O modules, actuators, and sensors. It supports deterministic execution of control logic to maintain predictable and consistent operation in critical industrial processes.

Its modular construction allows easy installation, maintenance, and system expansion. The 620‑2030 is engineered to handle continuous industrial operation with resistance to vibration, electrical noise, and environmental variations.

Product Applications

The 620‑2030 module is widely applicable in various industrial settings:

-

Central control of multi-rack PLC systems in factories.

-

Communication and coordination of distributed I/O devices in automation networks.

-

Integration into assembly lines, conveyors, and robotic control systems.

-

Retrofitting and upgrading legacy PLC systems to modern modular architectures.

-

Real-time monitoring and control in process industries, manufacturing, and material handling.

This module is suitable for both new installations and expansion of existing industrial automation systems.

Product Advantages

Key advantages of the Honeywell 620‑2030 include:

-

High Reliability: Designed for continuous industrial operation with minimal downtime.

-

Deterministic Logic Execution: Ensures precise and repeatable control performance.

-

Modular Design: Simplifies installation, maintenance, and expansion of PLC networks.

-

Industrial Durability: Resistant to vibrations, electrical interference, and moderate temperature fluctuations.

-

Status Indicators: LEDs for run, fault, and status monitoring enhance system visibility.

-

Flexible Integration: Works seamlessly with various sensors, actuators, and distributed I/O devices.

-

Ease of Maintenance: Plug-in rack design allows quick replacement without system downtime.

These advantages make it ideal for applications requiring high uptime and robust industrial control.

Product Specifications

| Parameter | Description |

|---|---|

| Model | 620‑2030 |

| Product Type | PLC Control and Interface Module |

| Core Function | Real-time logic execution and communication management |

| Compatible Platform | IPC 620 PLC systems |

| Installation Method | Rack-mounted plug-in module |

| Rated Voltage | 115 / 230 VAC |

| Processor Architecture | Industrial PLC processing unit |

| Memory | Non-volatile program memory |

| Operational Mode | Deterministic real-time control |

| Operating Temperature | 0°C to 55°C |

| Storage Temperature | -20°C to 70°C |

| Relative Humidity | 5% to 95% non-condensing |

| Diagnostic Indicators | Status, run, and fault LEDs |

| Dimensions | 245 × 130 × 65 mm |

| Weight (kg) | 1.37 kg |

Recommended Models – Same Series or Related Modules

| Model | Description | Dimensions | Weight (kg) |

|---|---|---|---|

| 620‑2031 | PLC interface and logic expansion module | 245 × 130 × 65 mm | 1.35 kg ( ) |

| 620‑2032 | High-performance PLC control unit | 245 × 135 × 65 mm | 1.40 kg ( ) |

| 620‑2033 | Multi-channel I/O interface module | 250 × 140 × 70 mm | 1.45 kg ( ) |

| 620‑2035 | Advanced logic processing module | 245 × 130 × 65 mm | 1.38 kg ( ) |

| 620‑2036 | Redundant PLC control module | 250 × 140 × 70 mm | 1.50 kg ( ) |

Recommended Popular Models – Same Brand

| Model | Product Type | Dimensions | Weight (kg) |

|---|---|---|---|

| 900G‑01 | Central PLC CPU module | 240 × 140 × 65 mm | 1.20 kg ( ) |

| 900H‑02 | High-capacity I/O controller | 260 × 150 × 70 mm | 1.40 kg ( ) |

| 900P‑05 | Industrial power supply module | 180 × 120 × 60 mm | 0.90 kg ( ) |

| 900C‑10 | Communications gateway module | 220 × 130 × 65 mm | 1.00 kg ( ) |

| 900R‑08 | Redundant control module | 250 × 150 × 70 mm | 1.50 kg ( ) |

Frequently Asked Questions (FAQ)

Q1: What is the main purpose of the 620‑2030 module?

A1: It executes real-time control logic and manages communication between PLCs and field devices.

Q2: Can the module operate continuously in industrial environments?

A2: Yes, it is designed for 24/7 industrial operation with high reliability.

Q3: How is the module installed?

A3: It is a rack-mounted plug-in module compatible with IPC 620 PLC systems.

Q4: Does it provide status or fault indicators?

A4: Yes, it has LEDs for run status, fault conditions, and operational status.

Q5: Can the 620‑2030 interface with multiple I/O devices?

A5: Yes, it supports integration with sensors, actuators, and distributed I/O modules.

Q6: Is it suitable for upgrading existing PLC systems?

A6: Yes, it can be integrated into legacy PLC networks for expansion or retrofitting.

Q7: What is the operating temperature range?

A7: The module operates safely between 0°C and 55°C.

Q8: Is it resistant to industrial vibrations and electrical interference?

A8: Yes, it is designed to handle typical industrial environmental conditions.

Q9: Can it be replaced or expanded easily?

A9: Yes, its modular plug-in design allows quick replacement or system expansion.

Q10: What is the expected service life of the 620‑2030 module?

A10: With proper installation and maintenance, it provides long-term reliable service in industrial settings.