ProductPRODUCT

Featured products

Contact Us

- Bently Nevada

- 330103-01-06-05-02-05

- 3300 XL 8 mm Proximity Probe

- USA

- 55 mm x 120 mm x 75 mm

- 0.65kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 47

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

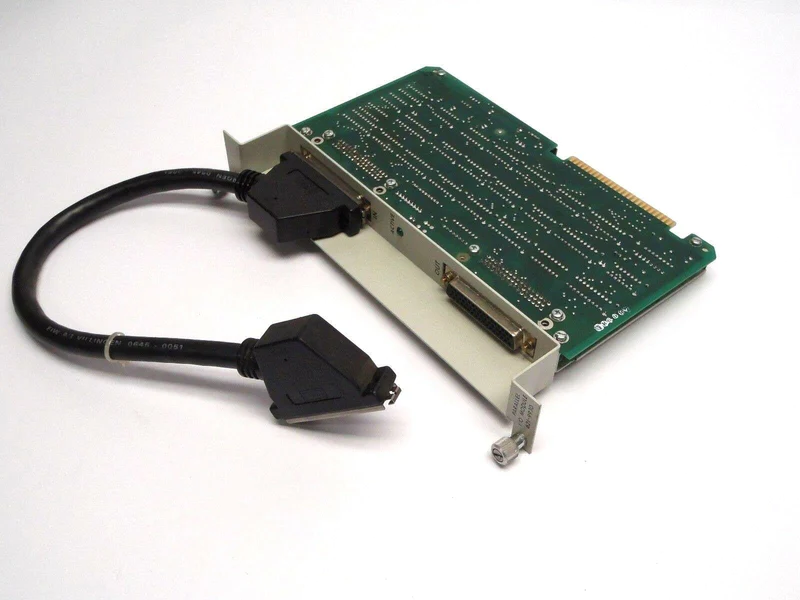

Bently Nevada 330103-01-06-05-02-05 Product Overview

The Bently Nevada 330103-01-06-05-02-05 is a highly advanced vibration monitoring sensor used to measure the condition of rotating machinery. It is part of Bently Nevada’s 3300 Series of products, which are designed to help businesses in various industries monitor their machinery’s health, detect problems early, and schedule maintenance before catastrophic failures occur. This sensor is engineered to deliver high accuracy in vibration measurement and provides essential data that can be used for predictive maintenance, reducing downtime and increasing machinery longevity.

In this detailed overview, we will explore the product’s specifications, its applications across industries, its advantages, and additional model recommendations.

Product Parameters

| Parameter | Details |

|---|---|

| Model Number | 330103-01-06-05-02-05 |

| Product Type | Vibration Monitoring Sensor |

| Measurement Type | Vibration, Displacement, and Velocity |

| Power Supply | 24V DC |

| Output Type | 4-20 mA / 0-10 V |

| Temperature Range | -40°C to +85°C |

| Dimensions (L x W x H) | 55 mm x 120 mm x 75 mm |

| Weight | 0.65 kg |

| Signal Processing | Digital and Analog Output |

| Mounting | DIN Rail Mounting |

Product Introduction

The Bently Nevada 330103-01-06-05-02-05 sensor is designed for real-time vibration monitoring of industrial machinery. It measures key parameters such as vibration, displacement, and velocity, offering operators critical data for ensuring equipment reliability and longevity. The sensor provides both analog (4-20 mA) and digital (0-10 V) output options, making it highly adaptable to various condition monitoring systems. Its robust construction allows it to operate efficiently in challenging industrial environments, with a temperature range from -40°C to +85°C.

This product is specifically designed to be integrated into machinery that requires continuous monitoring for predictive maintenance programs. With its compact size (55 mm x 120 mm x 75 mm), the 330103-01-06-05-02-05 sensor is easy to install, typically on DIN rails in control panels, saving space in industrial settings.

Product Applications

The Bently Nevada 330103-01-06-05-02-05 sensor has a wide range of applications across industries where machinery condition monitoring is critical. Key sectors include:

-

Power Generation – Monitoring turbines, generators, and compressors to ensure they run smoothly and avoid unexpected breakdowns.

-

Oil and Gas – Essential for monitoring pumps, motors, and compressors used in exploration, extraction, and transportation processes.

-

Manufacturing – Used to track motors, conveyors, and robotic systems, ensuring optimal performance in manufacturing plants.

-

Mining – Ideal for equipment such as crushers, mills, and conveyors, critical in mining operations where unplanned downtime can result in significant losses.

-

Water Treatment – Helps maintain the operational reliability of pumps, motors, and filtration systems, ensuring a constant supply of clean water.

The 330103-01-06-05-02-05 sensor is particularly valuable in any application where the failure of a critical piece of machinery can lead to operational disruptions, lost productivity, or safety hazards.

Product Advantages

-

High Precision: The 330103-01-06-05-02-05 offers highly accurate vibration, displacement, and velocity measurements, which are essential for detecting early signs of machinery failure.

-

Durable Design: Built to withstand harsh environmental conditions, the sensor can operate in temperatures ranging from -40°C to +85°C, ensuring reliability in a wide range of industrial settings.

-

Real-Time Monitoring: The continuous data provided by this sensor allows operators to take action quickly, minimizing downtime and avoiding costly repairs.

-

Versatile Output: The sensor provides both analog and digital output signals, which enhances its compatibility with a variety of monitoring systems.

-

Compact Size: The sensor’s compact design (55 mm x 120 mm x 75 mm) makes it easy to install in tight spaces, such as in control panels or machinery monitoring systems.

-

Easy Integration: With its standard DIN rail mounting, the sensor integrates seamlessly into existing monitoring systems, saving time and reducing installation costs.

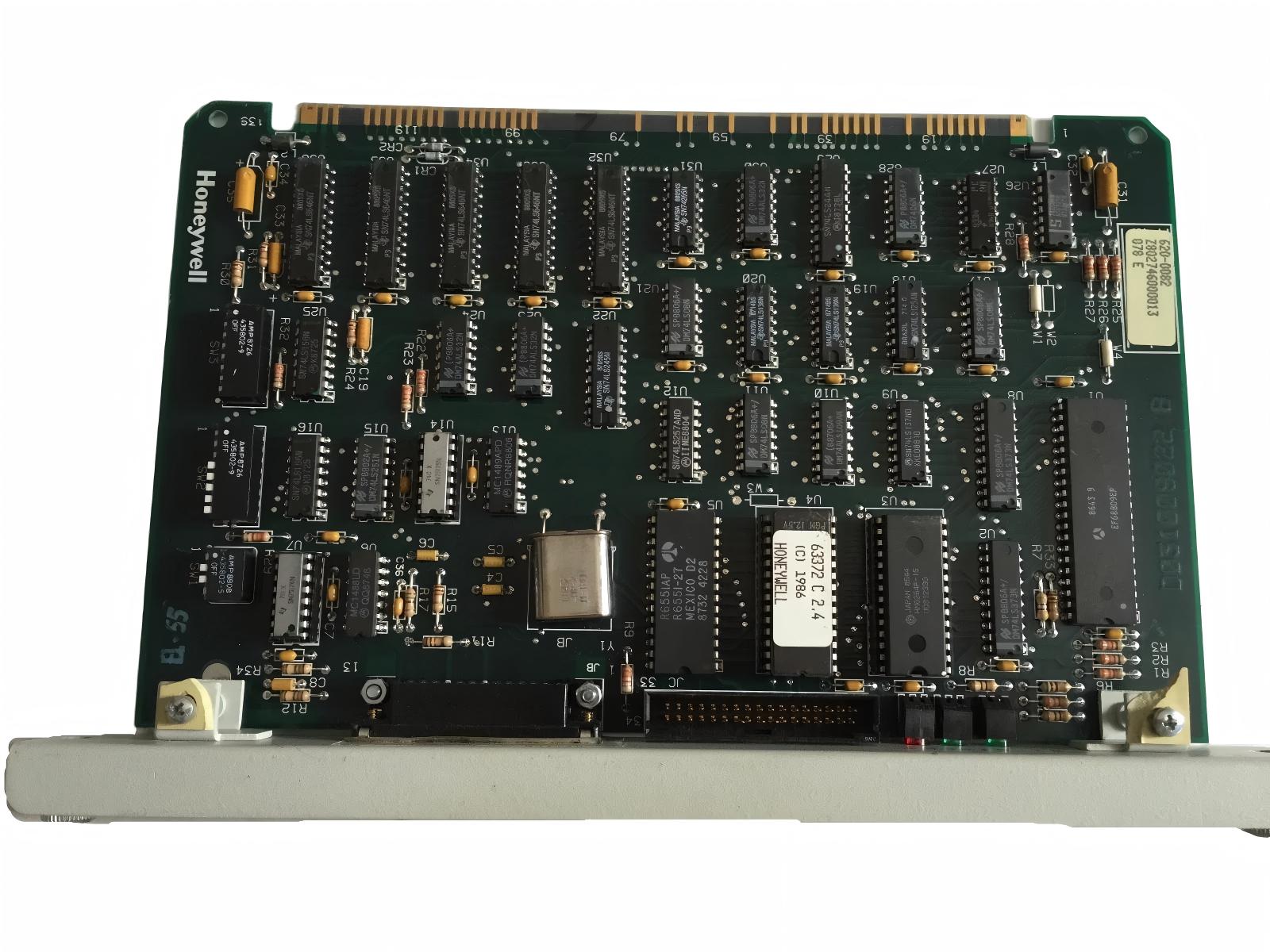

Brand Overview

Bently Nevada is a leading brand in the field of condition monitoring, specializing in vibration analysis and predictive maintenance technologies. Their solutions are designed to help industries ensure the continuous operation of critical machinery, thereby reducing downtime and increasing productivity. Bently Nevada’s products are renowned for their accuracy, reliability, and adaptability to diverse industrial environments, ranging from power generation to manufacturing and beyond.

Product Series

The 330103-01-06-05-02-05 sensor is part of the 3300 Series, a series of vibration and condition monitoring sensors developed by Bently Nevada. This series includes sensors designed for a variety of monitoring needs, from basic vibration analysis to complex predictive maintenance applications. The 3300 Series is known for its versatility, precision, and durability in demanding industrial environments.

Related Models in the 3300 Series

| Model Number | Description | Measurement Type | Dimensions (L x W x H) | Weight (kg) |

|---|---|---|---|---|

| 330103-01-06-05-02-01 | Vibration and Displacement Monitoring | Vibration, Displacement | 55 mm x 120 mm x 75 mm | 0.65 kg |

| 330104-01-06-05-02-05 | High-Velocity Vibration Monitoring | Velocity, Vibration | 55 mm x 130 mm x 80 mm | 0.7 kg |

| 330102-01-06-05-02-03 | Vibration Monitoring with Temperature | Vibration, Temperature | 60 mm x 125 mm x 80 mm | 0.75 kg |

| 330106-01-06-05-02-06 | Vibration Monitoring with Logging | Vibration, Velocity | 55 mm x 130 mm x 80 mm | 0.75 kg |

| 330106-01-06-05-02-07 | High Precision Vibration Sensor | Vibration, Displacement | 55 mm x 130 mm x 85 mm | 0.8 kg |

Popular Models from Bently Nevada

| Model Number | Description | Measurement Type | Dimensions (L x W x H) | Weight (kg) |

|---|---|---|---|---|

| 350101-01 | Vibration Monitor with Advanced Diagnostics | Vibration, Temperature | 60 mm x 120 mm x 70 mm | 0.8 kg |

| 350201-01 | Multi-Channel Vibration Monitoring | Vibration, Displacement | 65 mm x 140 mm x 80 mm | 1.0 kg |

| 3300/4 | Multi-Axis Vibration Sensor | Vibration, Velocity | 70 mm x 150 mm x 80 mm | 1.1 kg |

| 350601-01 | High-Speed Vibration Sensor | Vibration, Velocity | 60 mm x 130 mm x 75 mm | 0.9 kg |

| 330701-01 | Advanced Vibration Monitoring | Vibration, Displacement | 75 mm x 140 mm x 85 mm | 1.2 kg |

Frequently Asked Questions (FAQs)

Q1: What is the main purpose of the Bently Nevada 330103-01-06-05-02-05 sensor?

A1: The primary purpose of the 330103-01-06-05-02-05 is to monitor vibration, displacement, and velocity in rotating machinery, providing real-time data for predictive maintenance and condition monitoring.

Q2: In which industries is this sensor used?

A2: The sensor is commonly used in power generation, oil and gas, mining, manufacturing, and water treatment industries, where machinery reliability is crucial.

Q3: What type of output does the sensor provide?

A3: The 330103-01-06-05-02-05 provides both analog (4-20 mA) and digital (0-10 V) output options, making it compatible with a wide variety of monitoring systems.

Q4: How durable is the Bently Nevada 330103-01-06-05-02-05 sensor?

A4: The sensor operates in temperatures ranging from -40°C to +85°C, ensuring durability and reliable performance in harsh industrial environments.

Q5: How is the sensor mounted?

A5: The sensor can be easily mounted on a DIN rail, which is a standard method for installing industrial equipment in control panels.

Q6: What is the weight of the 330103-01-06-05-02-05 sensor?

A6: The weight of the sensor is 0.65 kg, making it lightweight and easy to install.

Q7: How does this sensor help in predictive maintenance?

A7: The sensor continuously monitors machinery, allowing operators to detect potential issues early and schedule maintenance before failure occurs, thus avoiding unplanned downtime.

Q8: Can the Bently Nevada 330103-01-06-05-02-05 sensor be used with other Bently Nevada products?

A8: Yes, the sensor can be integrated with other products in the 3300 Series and other Bently Nevada condition monitoring systems for a comprehensive solution.

Q9: Is this sensor suitable for high-speed applications?

A9: Yes, the sensor is designed to accurately measure high-speed vibrations, making it suitable for critical machinery applications.

Q10: Does the sensor require regular maintenance?

A10: The sensor is low-maintenance, requiring only periodic checks to ensure proper operation and signal output.