ProductPRODUCT

Featured products

Contact Us

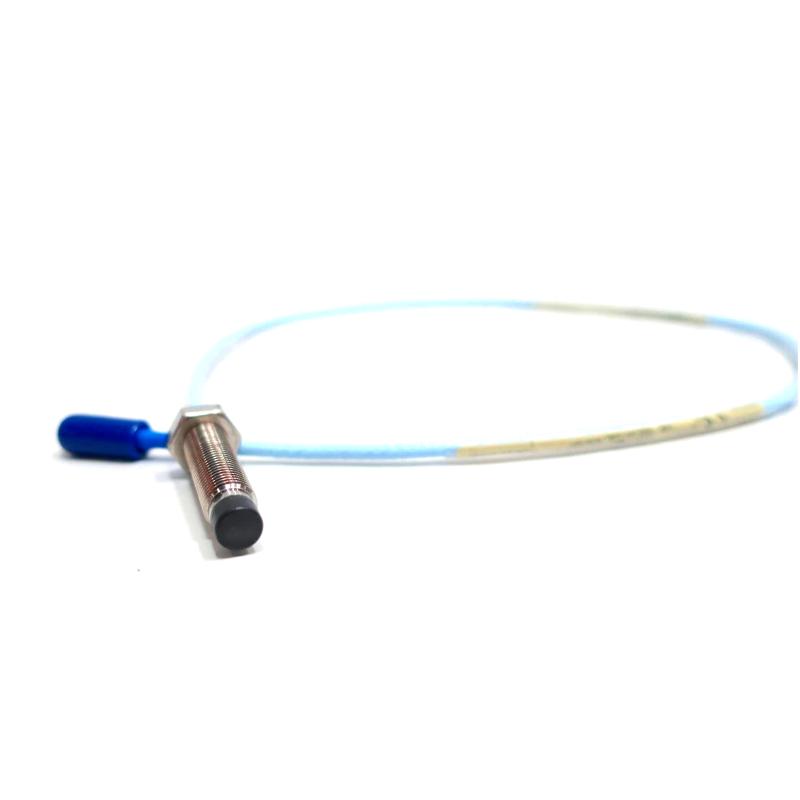

- Bently Nevada

- 330103-00-04-05-02-00

- 3300 XL 8 mm Proximity Probe

- USA

- 95 x 60 x 55 mm

- 0.34kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 60

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Product Overview: Bently Nevada 330103-00-04-05-02-00

Product Introduction

The Bently Nevada 330103-00-04-05-02-00 is a high-performance vibration sensor designed for precise condition monitoring of machinery. As part of the Bently Nevada 3300 Series, this sensor is engineered to monitor machinery health by measuring vibrations with high accuracy, enabling predictive maintenance. The sensor plays a crucial role in preventing unplanned downtime and costly repairs by detecting early signs of mechanical failure such as misalignments, imbalances, and bearing defects.

Built to endure harsh industrial environments, the sensor ensures reliable performance even under extreme operating conditions. It can be integrated into existing machinery monitoring systems and is commonly used in industries such as power generation, oil and gas, chemical processing, and manufacturing.

Product Applications

The 330103-00-04-05-02-00 vibration sensor is widely used in industries where reliable machinery health monitoring is critical for operational efficiency. Its primary applications include:

-

Power Generation: Monitoring critical equipment like turbines, generators, and pumps to ensure early detection of failures and prevent unexpected shutdowns.

-

Oil and Gas: Used in compressors, pumps, and motors to detect issues in real-time, allowing operators to take timely corrective actions.

-

Manufacturing: Employed in motors, conveyor belts, and other factory equipment to maintain smooth operations and prevent production halts.

-

Chemical Processing: Applied to pumps, mixers, and motors to detect vibration anomalies and improve the overall reliability of the plant.

-

Mining: Used to monitor crushers, mills, and other machinery in the mining industry, where equipment reliability is essential for continuous production.

Product Advantages

The Bently Nevada 330103-00-04-05-02-00 sensor offers several significant advantages that make it ideal for predictive maintenance applications:

-

High Accuracy: The sensor delivers precise vibration measurements, helping to detect even minor changes that could indicate potential issues.

-

Real-Time Monitoring: Provides continuous feedback on the health of machinery, enabling immediate action to be taken before problems escalate.

-

Durability: Built to withstand challenging environmental conditions such as extreme temperatures, vibrations, and exposure to chemicals, ensuring long-lasting performance.

-

Ease of Integration: Compatible with a wide range of existing condition monitoring systems, making it easy to incorporate into current setups.

-

Cost-Effective: By detecting faults early, the sensor helps prevent expensive repairs and downtime, ultimately reducing maintenance costs.

-

Low Maintenance: Requires minimal upkeep due to its durable design, ensuring reliable performance over the long term.

Brand Information

-

Brand: Bently Nevada

-

Series: 3300 Series

Product Series Overview

The Bently Nevada 3300 Series is a comprehensive range of vibration sensors and condition monitoring equipment designed for industrial applications. The sensors in the 3300 Series provide precise measurements that enable predictive maintenance and early fault detection, improving the reliability and lifespan of machinery. This series is well-known for its ease of use, robustness, and ability to withstand harsh operating environments.

The 3300 Series is used in various industries, including power generation, manufacturing, chemical processing, and more, providing businesses with critical insights into their machinery’s condition and preventing costly unplanned downtime.

Technical Specifications (Table Format)

| Parameter | Value |

|---|---|

| Model | Bently Nevada 330103-00-04-05-02-00 |

| Vibration Range | 0-200 mils (0-5.08 mm) |

| Output Signal | 4-20 mA |

| Operating Temperature | -40°C to +85°C |

| Supply Voltage | 18-30 VDC |

| Sensitivity | 100 mV/mil |

| Mounting Style | Bolt-on |

| Dimensions (L x W x H) | 95 x 60 x 55 mm |

| Weight | 0.34 kg |

Related Models from the Same Series

| Model | Vibration Range | Output Signal | Operating Temperature | Sensitivity | Weight |

|---|---|---|---|---|---|

| Bently Nevada 330103-00-04-05-01 | 0-100 mils (0-2.54 mm) | 4-20 mA | -40°C to +85°C | 100 mV/mil | 0.32 kg |

| Bently Nevada 330103-00-04-05-03 | 0-100 mils (0-2.54 mm) | 4-20 mA | -40°C to +85°C | 100 mV/mil | 0.31 kg |

| Bently Nevada 330103-00-04-10-01 | 0-500 mils (0-12.7 mm) | 4-20 mA | -40°C to +85°C | 100 mV/mil | 0.36 kg |

| Bently Nevada 330103-00-04-15-01 | 0-50 mils (0-1.27 mm) | 4-20 mA | -40°C to +85°C | 100 mV/mil | 0.33 kg |

| Bently Nevada 330103-00-04-10-02 | 0-100 mils (0-2.54 mm) | 4-20 mA | -40°C to +85°C | 100 mV/mil | 0.35 kg |

Popular Models from Bently Nevada

| Model | Vibration Range | Output Signal | Operating Temperature | Sensitivity | Weight |

|---|---|---|---|---|---|

| Bently Nevada 330103-00-03-05-01 | 0-100 mils (0-2.54 mm) | 4-20 mA | -40°C to +85°C | 100 mV/mil | 0.32 kg |

| Bently Nevada 330103-00-03-10-01 | 0-200 mils (0-5.08 mm) | 4-20 mA | -40°C to +85°C | 100 mV/mil | 0.34 kg |

| Bently Nevada 330103-00-03-15-01 | 0-50 mils (0-1.27 mm) | 4-20 mA | -40°C to +85°C | 100 mV/mil | 0.30 kg |

| Bently Nevada 330103-00-03-50-01 | 0-50 mils (0-1.27 mm) | 4-20 mA | -40°C to +85°C | 100 mV/mil | 0.31 kg |

| Bently Nevada 330103-00-03-30-01 | 0-50 mils (0-1.27 mm) | 4-20 mA | -40°C to +85°C | 100 mV/mil | 0.32 kg |

FAQ Section (QA Format)

Q1: What is the purpose of the Bently Nevada 330103-00-04-05-02-00 sensor?

A1: The sensor is designed to monitor machinery vibrations, helping detect early signs of mechanical failure, such as imbalances or bearing issues, and preventing costly downtime through predictive maintenance.

Q2: What industries use this vibration sensor?

A2: The sensor is used in industries like power generation, oil and gas, manufacturing, chemical processing, and mining to monitor critical machinery and improve operational efficiency.

Q3: How accurate is the vibration measurement provided by the sensor?

A3: The sensor provides highly accurate vibration measurements, capable of detecting even small changes in vibration that may indicate a potential problem.

Q4: What is the output signal type of this sensor?

A4: The sensor outputs a 4-20 mA signal, which is compatible with most industrial monitoring systems.

Q5: What is the temperature range in which the sensor operates?

A5: The 330103-00-04-05-02-00 sensor operates within a temperature range of -40°C to +85°C, suitable for a wide variety of industrial environments.

Q6: What is the vibration range of this sensor?

A6: This sensor has a vibration range of 0-200 mils (0-5.08 mm), making it suitable for applications requiring a broad measurement range.

Q7: How should the sensor be installed?

A7: The sensor uses a bolt-on mounting style, ensuring secure and stable attachment to machinery.

Q8: What is the weight of this sensor?

A8: The Bently Nevada 330103-00-04-05-02-00 sensor weighs approximately 0.34 kg, making it lightweight and easy to handle during installation.

Q9: How often should the vibration sensor be calibrated?

A9: Calibration of the sensor should be performed periodically, typically every 6 to 12 months depending on the application and operating environment. Regular calibration ensures that the sensor continues to provide accurate measurements.

Q10: Can this sensor be used in hazardous environments?

A10: Yes, the Bently Nevada 330103-00-04-05-02-00 vibration sensor is designed to withstand harsh and hazardous industrial environments, such as high temperatures, extreme vibrations, and exposure to chemicals, ensuring reliable performance even in challenging conditions.