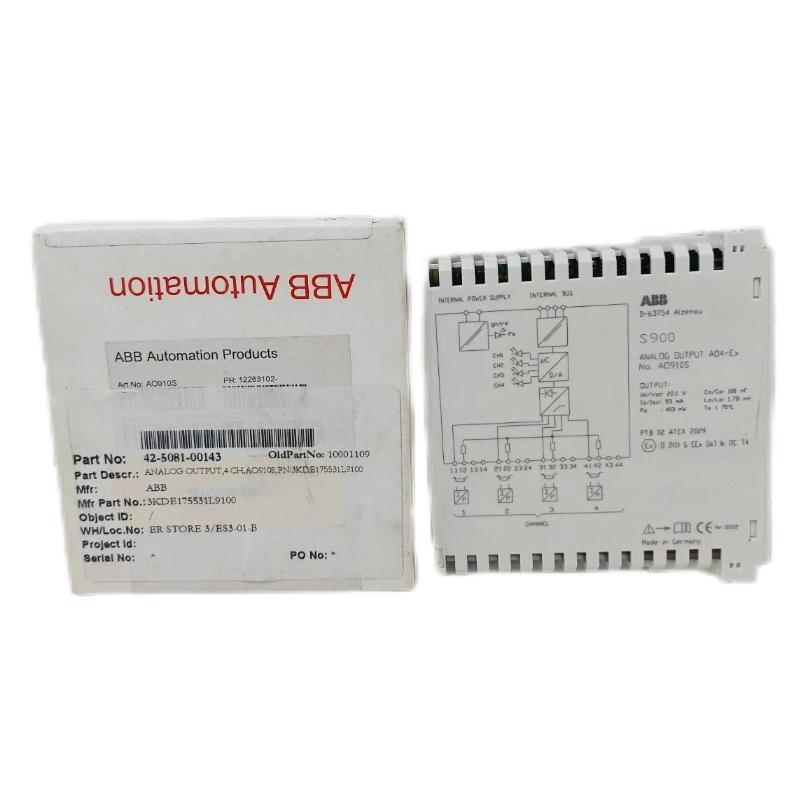

ProductPRODUCT

Featured products

Contact Us

- Yokogawa

- YCB311-M250

- Vnet Cable DCS Cable

- Japan

- 300mm x 285mm x 230mm

- 6.2kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 124

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Yokogawa YCB311-M250 Product Overview

Model: Yokogawa YCB311-M250

Brand: Yokogawa

Series: YCB Series

Product Introduction

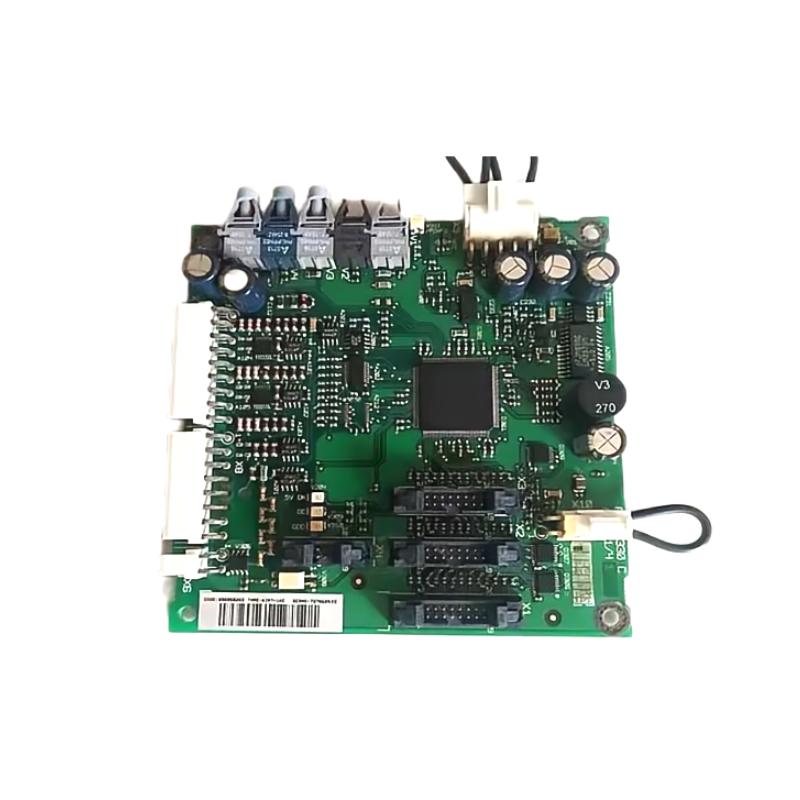

The Yokogawa YCB311-M250 is a high-performance process controller designed to provide advanced process automation, control, and monitoring across various industrial sectors. As part of the YCB Series, this model is engineered for precision control, real-time monitoring, and enhanced system flexibility. The YCB311-M250 offers an ideal solution for industries requiring robust process control with complex system integration capabilities.

With a focus on high-speed data processing, adaptive control algorithms, and flexible input/output configuration, the YCB311-M250 ensures that your systems operate at peak performance, delivering consistent and reliable results. This product is ideal for integration into large-scale, high-demand systems, offering scalable options for complex automation tasks.

Product Applications

-

Chemical and Pharmaceutical Manufacturing: The YCB311-M250 provides precise control for chemical reactors, batch processes, and continuous production systems where maintaining specific conditions (temperature, pressure, flow rates) is crucial.

-

Power Generation: In power plants, the YCB311-M250 optimizes turbine performance, power distribution, and grid management. It also helps monitor critical components such as boilers, generators, and transformers.

-

Water and Wastewater Treatment: Ideal for controlling pumps, filtration systems, chemical dosing, and water quality monitoring systems in both municipal and industrial water treatment plants.

-

Oil and Gas Processing: It supports advanced control and monitoring of refining processes, pipelines, and storage facilities, ensuring efficiency, safety, and reliability.

-

Automated Manufacturing and Robotics: The YCB311-M250 is used in automated assembly lines, robotics systems, and production plants to maintain consistent product quality and reduce operational downtime.

Product Advantages

-

High-Precision Control: The YCB311-M250 utilizes advanced PID control algorithms, adaptive control, and real-time optimization to ensure high-precision control across multiple variables in complex industrial processes.

-

Flexible Input/Output Configuration: It offers a wide range of compatible input and output types, allowing for customized configurations to meet specific application requirements.

-

Scalable and Modular Design: The system’s modular design allows for easy scaling, enabling users to add or remove components to expand or adapt the system according to changing needs.

-

Multi-Protocol Support: The YCB311-M250 supports a variety of communication protocols, including Modbus RTU, Profibus DP, and Ethernet/IP, ensuring compatibility with existing industrial networks and third-party equipment.

-

User-Friendly Interface: With its intuitive HMI (Human-Machine Interface), operators can easily configure, monitor, and troubleshoot the system, reducing training time and operational errors.

-

Durability in Harsh Environments: The YCB311-M250 is designed to withstand tough industrial environments, featuring an IP65 rating for dust and water resistance, ensuring long-lasting reliability even in extreme conditions.

Product Specifications

| Parameter | Description |

|---|---|

| Model | Yokogawa YCB311-M250 |

| Power Supply | 24V DC ± 10% |

| Control Type | Digital PID, Adaptive Control Algorithms |

| Input Interface | 4-20mA, 0-10V, RTD, Thermocouple, Digital Inputs |

| Output Interface | 4-20mA, Relay Outputs (contact), Digital Outputs |

| Communication Protocol | Modbus RTU, Profibus DP, Ethernet/IP |

| Operating Temperature | -10°C to +60°C |

| Storage Temperature | -20°C to +70°C |

| Dimensions | 300mm x 285mm x 230mm |

| Weight | 6.2kg |

| Protection Rating | IP65 |

| Certifications | CE, UL, RoHS |

Recommended Models

1. Models in the Same Series

| Model | Description | Key Features | Dimensions | Weight |

|---|---|---|---|---|

| YCB312-M250 | Advanced control for large-scale applications | Features enhanced I/O capacity, real-time monitoring, and adaptive feedback | 310mm x 290mm x 240mm | 6.5kg |

| YCB313-M250 | Flexible, modular control system | Ideal for multi-zone control, suitable for energy management and large plants | 300mm x 285mm x 230mm | 6.3kg |

| YCB314-M250 | High-performance feedback control | Real-time control system with fast data processing capabilities | 310mm x 290mm x 240mm | 6.6kg |

| YCB315-M250 | Energy-efficient and scalable | Offers real-time optimization and modular I/O for large processes | 305mm x 290mm x 235mm | 6.4kg |

| YCB316-M250 | Real-time process optimization | Optimized for large, complex systems requiring continuous monitoring and adaptive control | 300mm x 285mm x 230mm | 6.5kg |

2. Popular Models from the Same Brand

| Model | Description | Key Features | Dimensions | Weight |

|---|---|---|---|---|

| YOKO-34712 | Real-time industrial process controller | Advanced real-time feedback and process optimization | 315mm x 300mm x 250mm | 6.7kg |

| YOKO-45893 | Modular automation control system | Features flexible I/O and high-speed data processing | 320mm x 310mm x 260mm | 7.0kg |

| YOKO-57832 | High-speed data-driven control system | High-performance system with fast response times | 300mm x 290mm x 230mm | 6.3kg |

| YOKO-67934 | Energy management system | Optimized for energy generation and consumption monitoring | 310mm x 295mm x 240mm | 6.6kg |

| YOKO-78956 | Advanced feedback controller for automation | Suitable for manufacturing, energy, and chemical industries | 305mm x 295mm x 235mm | 6.4kg |

Frequently Asked Questions (FAQ)

Q1: What power supply does the YCB311-M250 require?

A1: The YCB311-M250 requires a 24V DC ± 10% power supply.

Q2: Can I integrate the YCB311-M250 into my existing control system?

A2: Yes, the YCB311-M250 supports Modbus RTU, Profibus DP, and Ethernet/IP, allowing seamless integration with existing systems.

Q3: What is the operating temperature range of the YCB311-M250?

A3: The YCB311-M250 operates between -10°C to +60°C and can be stored at temperatures from -20°C to +70°C.

Q4: How easy is it to maintain the YCB311-M250?

A4: The YCB311-M250’s modular design makes maintenance straightforward. Components can be easily replaced or upgraded without requiring significant downtime.

Q5: Does the YCB311-M250 support remote control?

A5: Yes, the YCB311-M250 supports remote monitoring and control via Ethernet/IP, enabling you to manage the system from a central location.

Q6: What types of inputs are compatible with the YCB311-M250?

A6: The YCB311-M250 supports a variety of inputs, including 4-20mA, 0-10V, RTD, thermocouple, and digital inputs.

Q7: Is the YCB311-M250 suitable for harsh environments?

A7: Yes, the YCB311-M250 is IP65-rated, making it dust-tight and resistant to water jets, which is ideal for demanding industrial environments.

Q8: Can I expand the I/O capacity of the YCB311-M250?

A8: Yes, the YCB311-M250 features a modular I/O design, allowing you to add or remove I/O modules based on your specific requirements.

Q9: What output options does the YCB311-M250 support?

A9: The YCB311-M250 supports 4-20mA, relay outputs (contact), and digital outputs, providing flexibility for controlling external devices.

Q10: What certifications does the YCB311-M250 have?

A10: The YCB311-M250 is CE, UL, and RoHS certified, ensuring it meets international safety and environmental standards.