ProductPRODUCT

Featured products

Contact Us

- Emerson

- A6410

- Valve And Case Expansion Monitor

- USA

- 130 mm × 185 mm × 65 mm

- 0.54kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 149

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

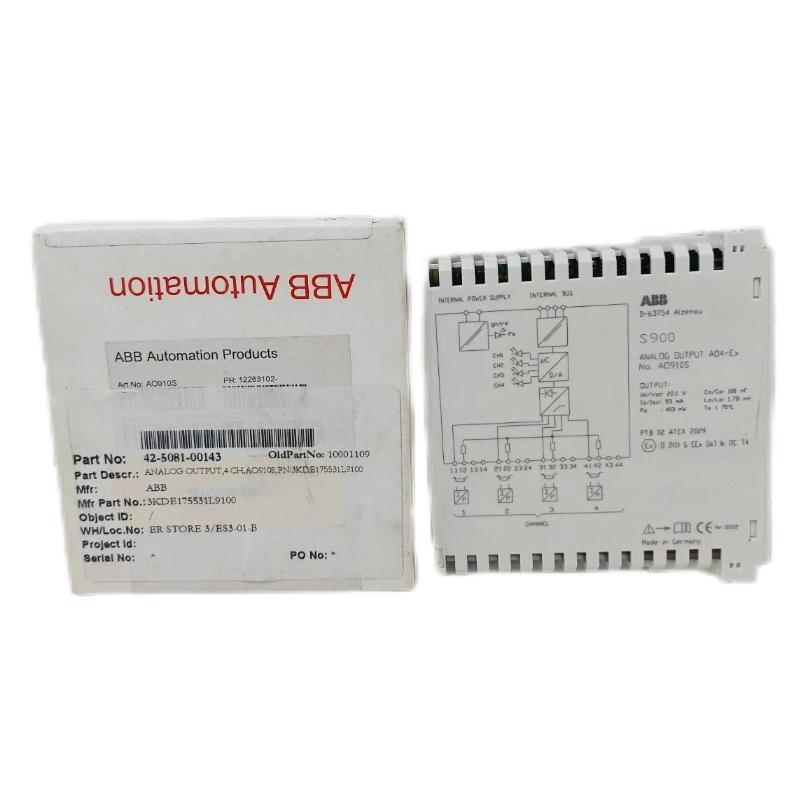

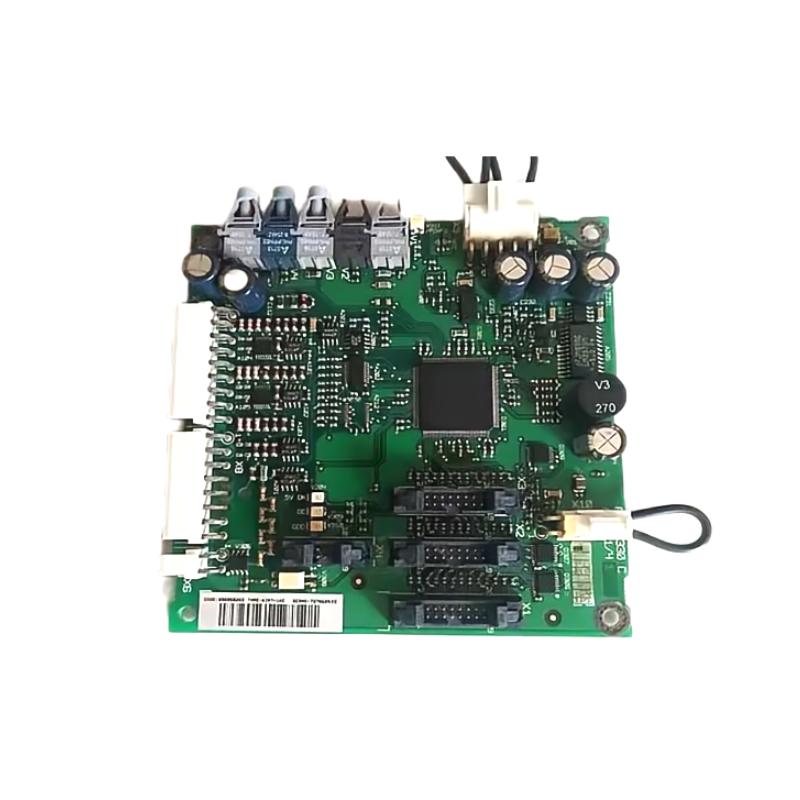

Product Introduction

The Emerson A6410 is a high-performance Vibration Monitoring and Protection Module designed for continuous condition monitoring of rotating machinery such as turbines, compressors, pumps, motors, and generators. It provides accurate, real-time vibration measurement and protection to prevent mechanical failures and unplanned downtime.

Belonging to the AMS 6300 Machinery Health Monitoring Series, the A6410 offers advanced diagnostic capabilities, flexible sensor inputs, and compatibility with safety and control systems. With robust signal processing and high-speed response, it ensures reliable performance in critical industrial environments that demand 24/7 operational safety and efficiency.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | A6410 |

| Brand | Emerson |

| Series | AMS 6300 Machinery Health Monitoring Series |

| Type | Vibration Monitoring and Protection Module |

| Input Channels | 4 vibration or proximity sensor inputs |

| Input Signal Type | IEPE accelerometers, velocity probes, or proximity sensors |

| Input Range | ±24 V DC, sensitivity 100 mV/g typical |

| Frequency Range | 0.1 Hz to 20 kHz |

| Sampling Rate | Up to 100 kHz per channel |

| Dynamic Range | 96 dB typical |

| Output Channels | 2 analog outputs (4–20 mA or 0–10 V); 4 relay outputs |

| Digital Communication | RS-485 / Modbus RTU / optional Ethernet |

| Power Supply | 24 V DC ±10 % |

| Power Consumption | 6 W typical |

| Response Time | <10 ms |

| Mounting Type | DIN-rail or rack mountable |

| Operating Temperature | –20 °C to +65 °C |

| Storage Temperature | –40 °C to +85 °C |

| Humidity | 5 % to 95 % (non-condensing) |

| Isolation Voltage | 1500 V RMS channel-to-bus isolation |

| Protection | Overvoltage and reverse polarity protection |

| Dimensions (W × H × D) | 130 mm × 185 mm × 65 mm |

| Weight | 0.54 kg |

| Certifications | CE, UL, RoHS, ISO 13849 |

| Typical Application Fields | Turbines, compressors, pumps, motors, generators, process machinery |

Product Advantages

-

High Precision Vibration Measurement: The A6410 offers 24-bit resolution with wide dynamic range to capture the most subtle changes in machine vibration patterns.

-

Multi-Sensor Compatibility: Supports accelerometers, proximity probes, and velocity sensors for diverse monitoring configurations.

-

Fast Real-Time Protection: Provides near-instantaneous trip relay activation in case of vibration threshold breach, ensuring equipment safety.

-

Scalable and Modular Design: Easily integrates into existing monitoring systems; modules can be expanded for multi-channel setups.

-

Strong Electromagnetic Immunity: Robust noise filtering and isolation design enable operation in harsh industrial electromagnetic environments.

-

Flexible Output Options: Analog, digital, and relay outputs provide seamless connection to DCS, PLC, and SCADA systems.

-

Reliable and Durable: Built for continuous operation under vibration, humidity, and temperature variations typical in industrial plants.

Applications

The A6410 module is designed for continuous vibration monitoring and machine protection in:

-

Power Generation: Monitoring turbines, generators, and auxiliary pumps to ensure safe and efficient operation.

-

Oil & Gas: Supervising compressors, turbines, and drilling equipment under high mechanical load.

-

Petrochemical & Refining: Detecting abnormal vibration in pumps and rotating units to prevent process interruptions.

-

Marine & Offshore: Monitoring propulsion machinery, turbines, and drives in demanding offshore conditions.

-

Manufacturing & Steel Plants: Condition monitoring of rolling mills, conveyors, and heavy-duty motors.

Brand and Series Information

-

Brand: Emerson

-

Series: AMS 6300 Machinery Health Monitoring Series

The AMS 6300 series is a suite of intelligent vibration, speed, and process condition monitoring modules. Designed to detect early signs of equipment degradation, this series allows predictive maintenance, operational safety, and improved plant efficiency.

Each module in the AMS 6300 family provides consistent electrical design, communication compatibility, and modular flexibility, supporting both stand-alone and networked installations.

Related Models (Same Series or Equivalent)

| Model | Type | Description | Key Specifications |

|---|---|---|---|

| A6310 | Vibration Input Module | 8-channel vibration input module for rotating equipment | Frequency 0.1–20 kHz; 130×185×65 mm; 0.52 kg |

| A6320 | Dual Channel Protection Module | 2-channel protection module for critical assets | 24 V DC; relay output; 0.50 kg |

| A6330 | Machine Health Module | Condition monitoring with FFT analysis | 4 inputs; Modbus communication; 0.53 kg |

| A6350 | Combined Vibration and Speed Module | Monitors vibration + shaft speed; integrated alarms | 24 V DC; DIN-rail mount; 0.55 kg |

| A6370D | Overspeed Protection Module | Monitors overspeed and reverse rotation | 0–20 kHz; SIL 3 certified; 0.49 kg |

Popular Models from the Same Brand

| Model | Series | Type | Description / Key Specs |

|---|---|---|---|

| KJ4001X1-BA1 | DeltaV | Controller Processor Module | 24 V DC supply; 150×185×70 mm; 0.56 kg |

| VE4003S2B1 | DeltaV | Communication Interface | 24 V DC; 130×185×65 mm; 0.50 kg |

| VE4002S1T2B1 | Ovation | Digital Output Module | 24 V DC; 130×185×65 mm; 0.46 kg |

| KJ2003X1-BB1 | DeltaV | Analog Output Module | 0–10 V / 4–20 mA; 130×185×65 mm; 0.48 kg |

| VE4005S2B1 | Ovation | Analog Input Module | 0–20 mA / 4–20 mA; 130×185×65 mm; 0.52 kg |

FAQ (Frequently Asked Questions)

Q1: What is the purpose of the A6410 module?

A1: The A6410 monitors vibration signals to detect early signs of imbalance, misalignment, or bearing failure in rotating machinery.

Q2: How many input channels does the A6410 have?

A2: It features 4 independent vibration/proximity input channels.

Q3: What types of sensors can be connected to the A6410?

A3: It supports accelerometers, velocity probes, and proximity probes (eddy-current type).

Q4: Does the A6410 provide protection outputs?

A4: Yes, it includes 4 programmable relay outputs and 2 analog outputs (4–20 mA).

Q5: Can the A6410 be used in hazardous environments?

A5: Yes, it is designed for industrial environments with robust isolation and CE/UL certifications.

Q6: What is the module’s power requirement?

A6: 24 V DC ±10 %, with a typical power consumption of 6 W.

Q7: What communication interfaces are available?

A7: RS-485, Modbus RTU, and optional Ethernet are available for system integration.

Q8: What is the response time of the A6410?

A8: Less than 10 milliseconds, allowing fast protection activation.

Q9: What are its dimensions and weight?

A9: 130 mm × 185 mm × 65 mm; weight approximately 0.54 kg.

Q10: Is it compatible with AMS software platforms?

A10: Yes, it integrates seamlessly with AMS Machinery Health systems for configuration and diagnostics.